Method for ultrasonically detecting orientation degree of pipe on line

A technology of orientation degree and ultrasonic wave, which is applied in the direction of material analysis, measuring device, and analytical material using sound wave/ultrasonic wave/infrasonic wave. It can solve problems such as lack of advantages, difficulty in sample preparation, and limitation of sonic method, and achieve automation and intelligence. The effect of chemicalization, strong penetrating power and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Establishing an online orientation detection system includes the following steps:

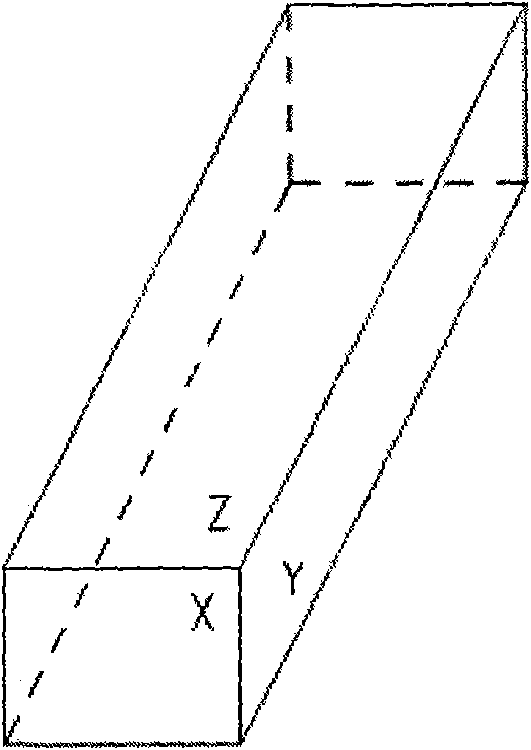

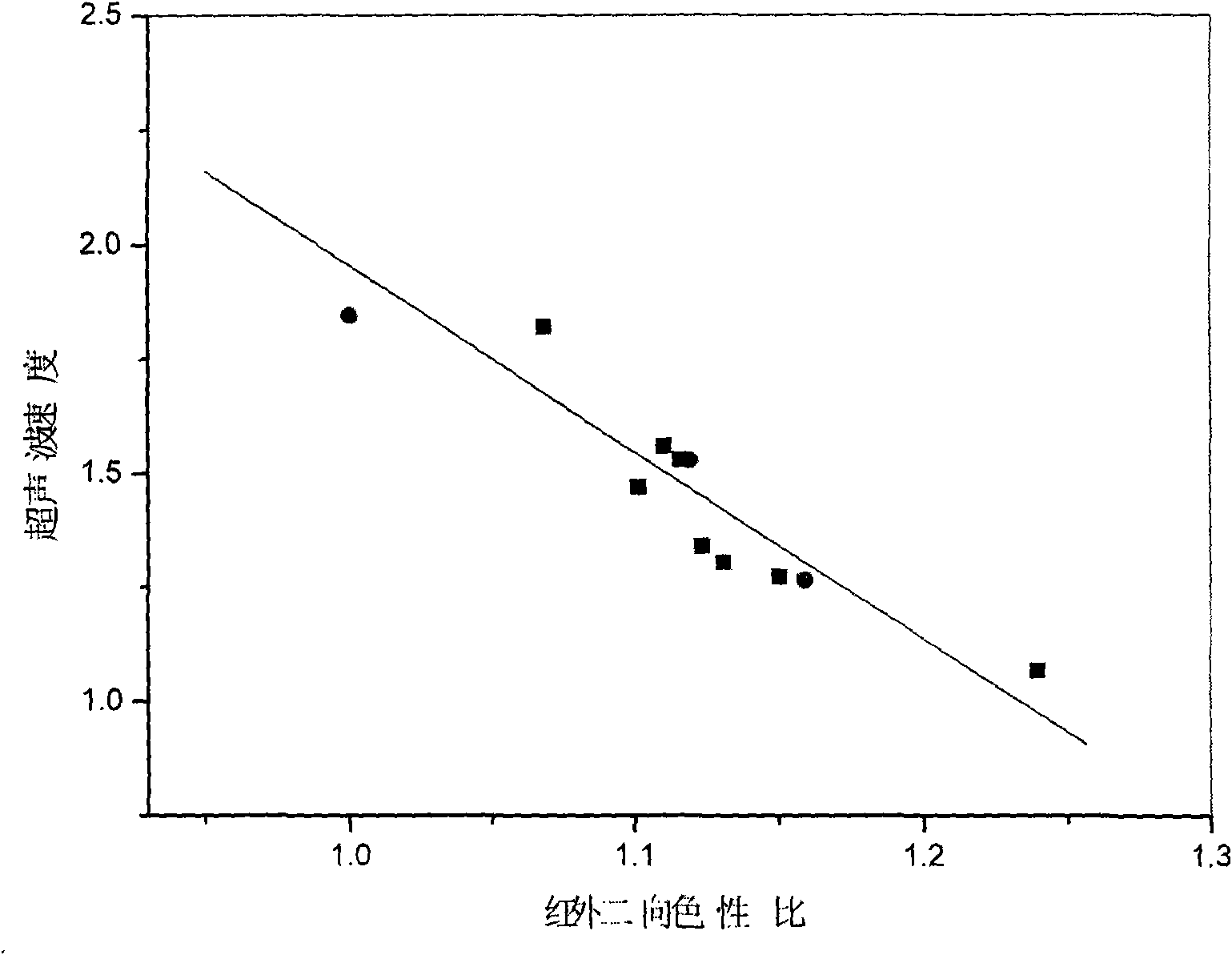

[0014] (1) Measure the ultrasonic velocity perpendicular to the orientation direction for samples with different orientation degrees.

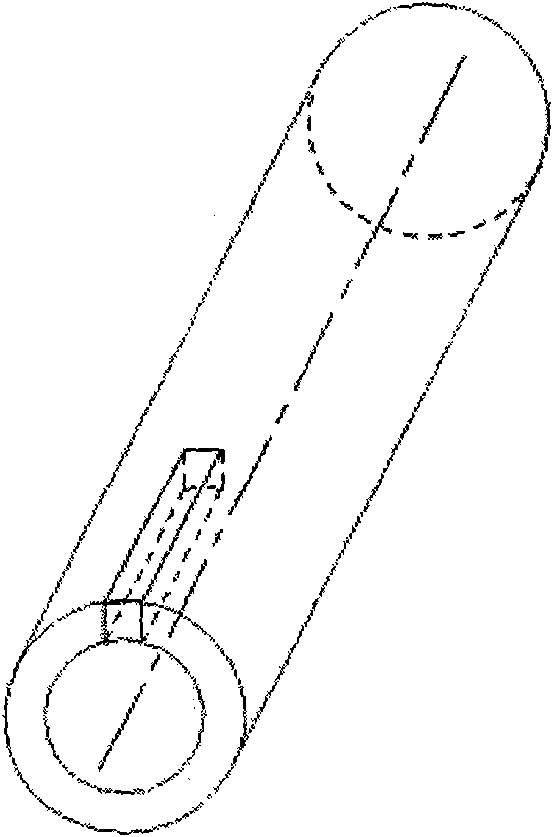

[0015] Ultrasonic testing instrument, the GIMI2 ultrasonic online monitor developed by the Industrial Materials Institute of the National Research Council of Canada (IndustrialMaterials Institute, National Research Council Canada). For samples with different degrees of orientation, the sound wave will slow down if the test is performed perpendicular to the direction of orientation. The invention uses ultrasonic waves to measure the wave velocity of the sample perpendicular to the orientation direction. This method is mainly for the convenience of being applied to the on-line detection of the orientation degree on the PVC-O pipe production line in the future.

[0016] (2) Using infrared dichroism method to accurately measure the degree of orientation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com