Method for measuring quality and flow of light oil product by using ultrasonic waves

A technology of mass flow and light oil, which is applied in the field of pipeline transportation, ultrasonic mass flow measurement of light oil, and mass flow measurement during filling, which can solve the problems of inconvenient accurate measurement and improve the accuracy of measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] According to existing literature, in ultrasonic mass flow measurement, its fluid mass flow q m It can be obtained by formula (1): q m =ρq v =ρAu (1);

[0033] Where q m Is the mass flow rate (kg / S), q v Is the volume flow (L / S), ρ is the oil density (Kg / L), A is the cross-sectional area of the ultrasonic measuring pipe (cm 2 ), u is the average flow velocity of the fluid interface (cm / S).

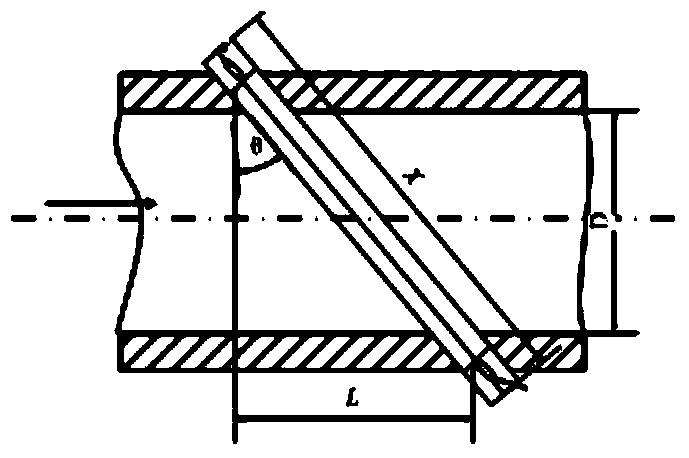

[0034] In the present invention, the cross-sectional average flow rate is measured by the plug-in time difference method. The technical method can be seen in the well-known ultrasonic flow measurement method and technology, which is outside the scope of the present invention. Here, the ultrasonic density measurement method is mainly described.

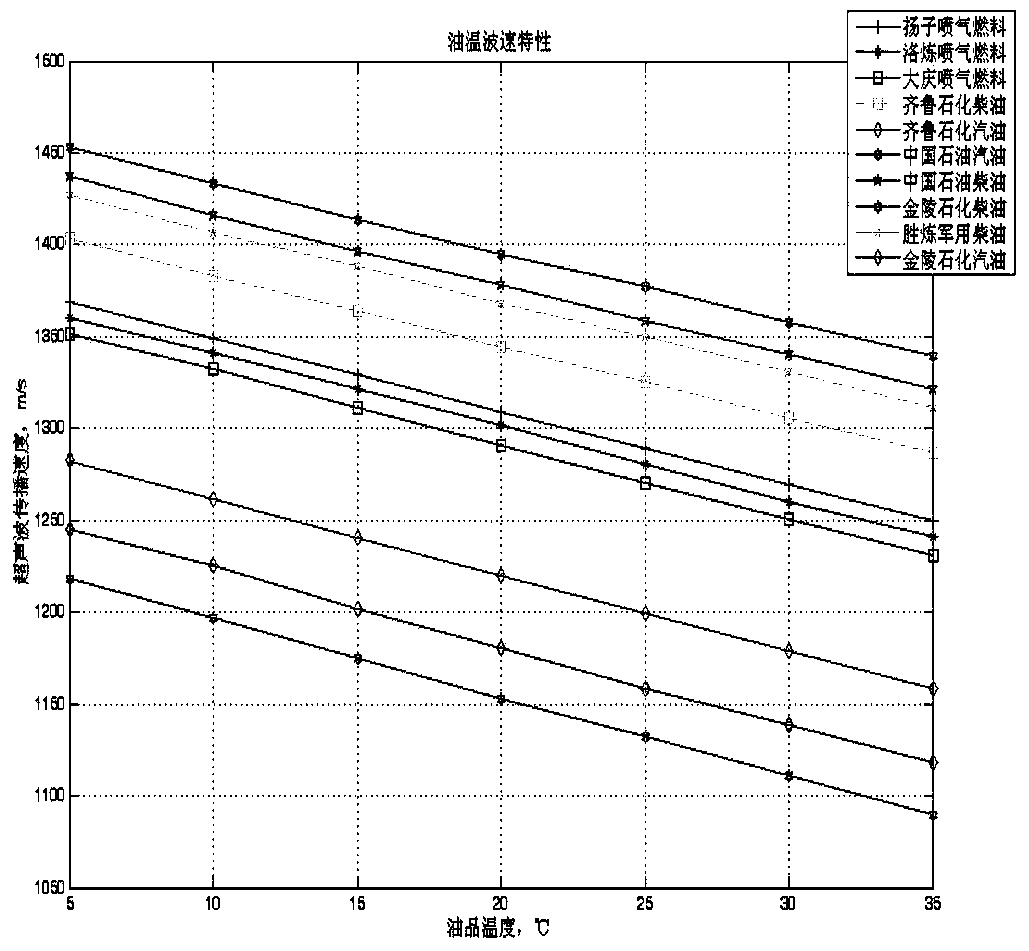

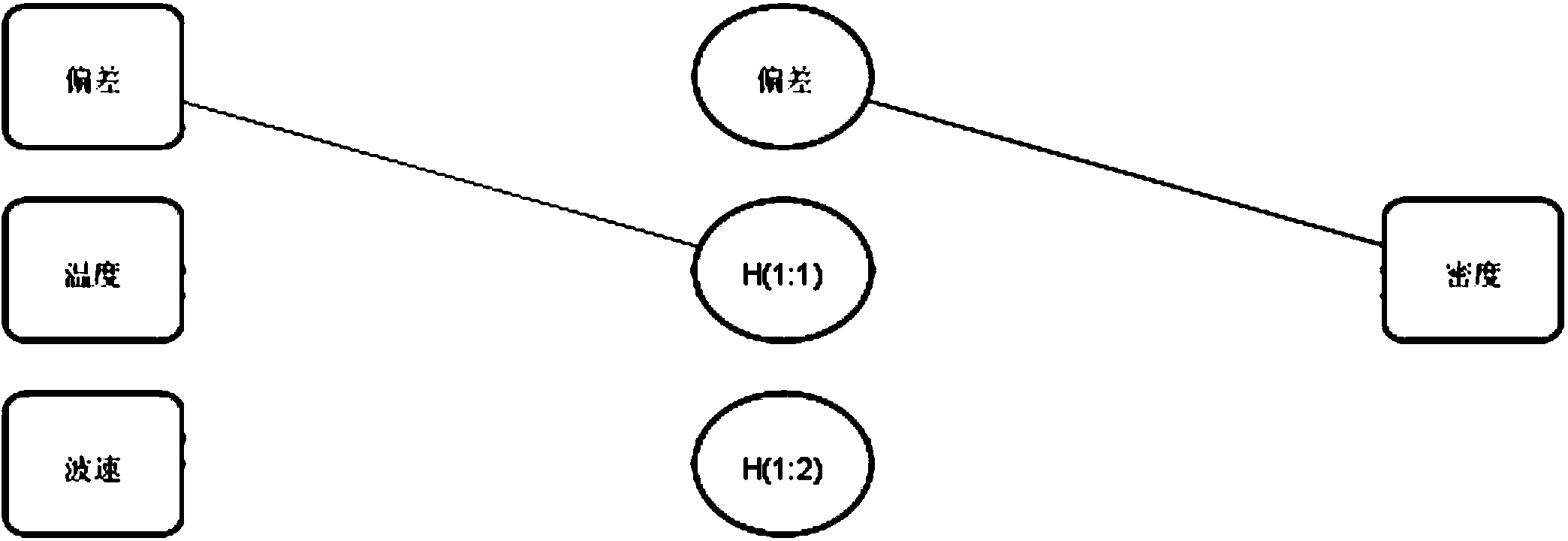

[0035] The ultrasonic density measurement method is as follows: first use the upstream and downstream ultrasonic delay of the existing time delay ultrasonic flowmeter to calculate the ultrasonic propagation velocity c of the static medium, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com