Method and device for online representing crystallization kinetic process through ultrasonic wave

An ultrasonic and kinetic technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, measurement devices, and material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as difficult on-line characterization, achieve easy high-pressure testing, and convenient formulations Research and product quality evaluation, optimize the effect of cooling and solidification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

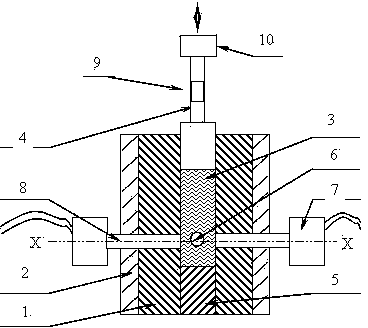

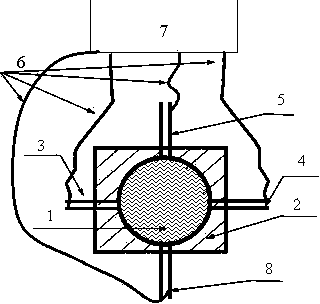

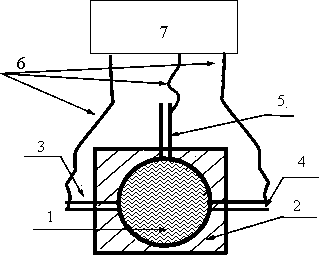

[0028] Implementation plan one: with figure 1 The material cavity of the PVT test device is equipped with an ultrasonic probe to conduct online tests on the cooling process of the polypropylene melt, and obtain the synchronous corresponding curves of the specific volume of polypropylene under isothermal and isobaric conditions and the velocity of ultrasonic sound transmitted therein versus time, see Figure 4 and Figure 5 .

[0029] At a certain temperature T and pressure P, the ultrasonic sound velocity transmitted in the material is uniquely corresponding to its specific volume, and the curves are almost parallel under different pressures; under a certain pressure, Figure 4 The variation curve of medium ultrasonic sound velocity with temperature and Figure 5 The change curve of medium specific volume with temperature is similar, and the inflection point of the sound velocity curve can determine the crystallization start temperature (T CS ) and end temperature (T CE )....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com