Vapor-water mixed heating device

A heating device and steam-water mixing technology, which is applied to lighting and heating equipment, heat exchanger types, direct contact heat exchangers, etc., can solve the problems of small adjustment range and poor stability, and achieve wide adjustment range and low mixing noise , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

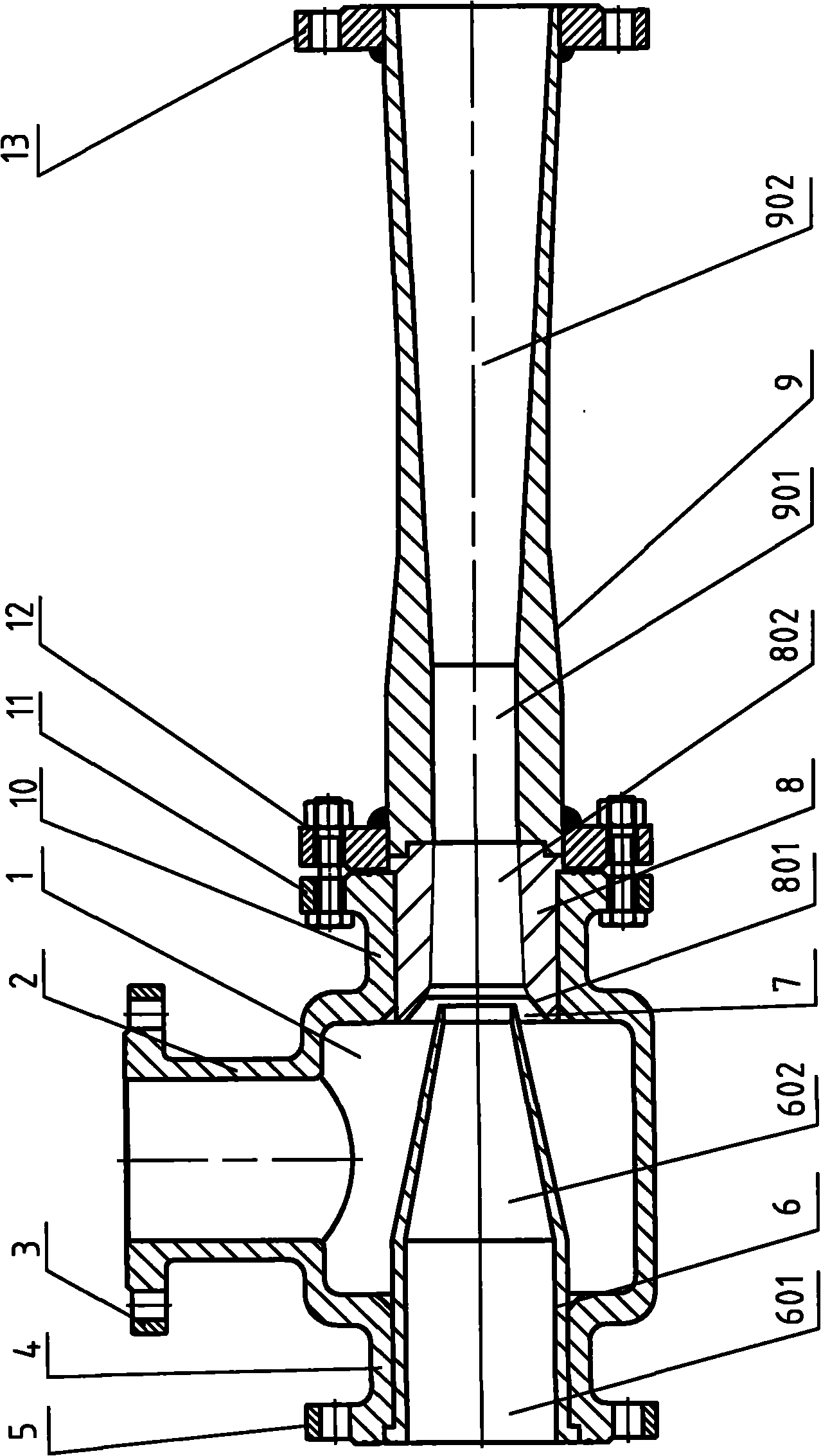

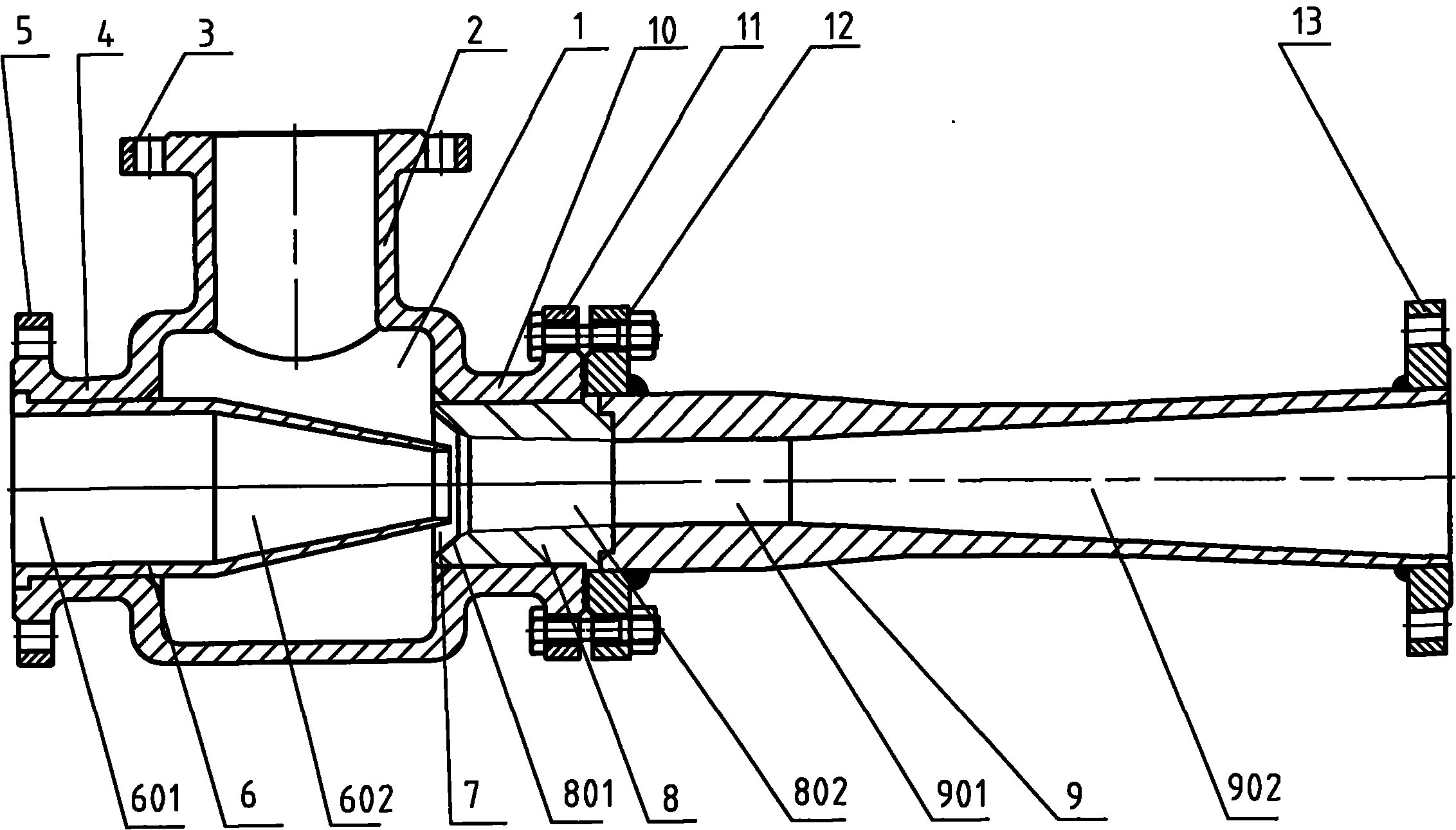

[0012] In the accompanying drawings, a steam-water mixing heating device includes a steam-water heating chamber 1 .

[0013] A water inlet pipe 4 , a steam inlet pipe 2 and a water outlet pipe 10 are respectively provided on the chamber wall of the steam-water heating chamber 1 .

[0014] The water inlet pipe 4 and the water outlet pipe 10 are on the same axis. The steam inlet pipe 2 is located on the chamber wall of the steam-water heating chamber 1 between the water inlet pipe 4 and the water outlet pipe 10 .

[0015] The inlet of the water inlet pipe 4, the inlet of the steam inlet pipe 2 and the outlet of the water outlet pipe 10 are respectively provided with flanges 5, 3, 11.

[0016] As shown in the drawings, a tapered nozzle 6 is provided in the water inlet pipe 4, and a cylindrical water inlet chamber 601 and a frusto-conical spray chamber 602 are arranged on the coaxial line in the pipe body of the tapered nozzle 6. The taper of the frusto-conical spray chamber 602...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com