Ultrasonic detection system of quantitative contact pressure, and detection method thereof

A technology of contact pressure and detection system, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, and can solve the problem of inability to detect changes in rock samples to be tested.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

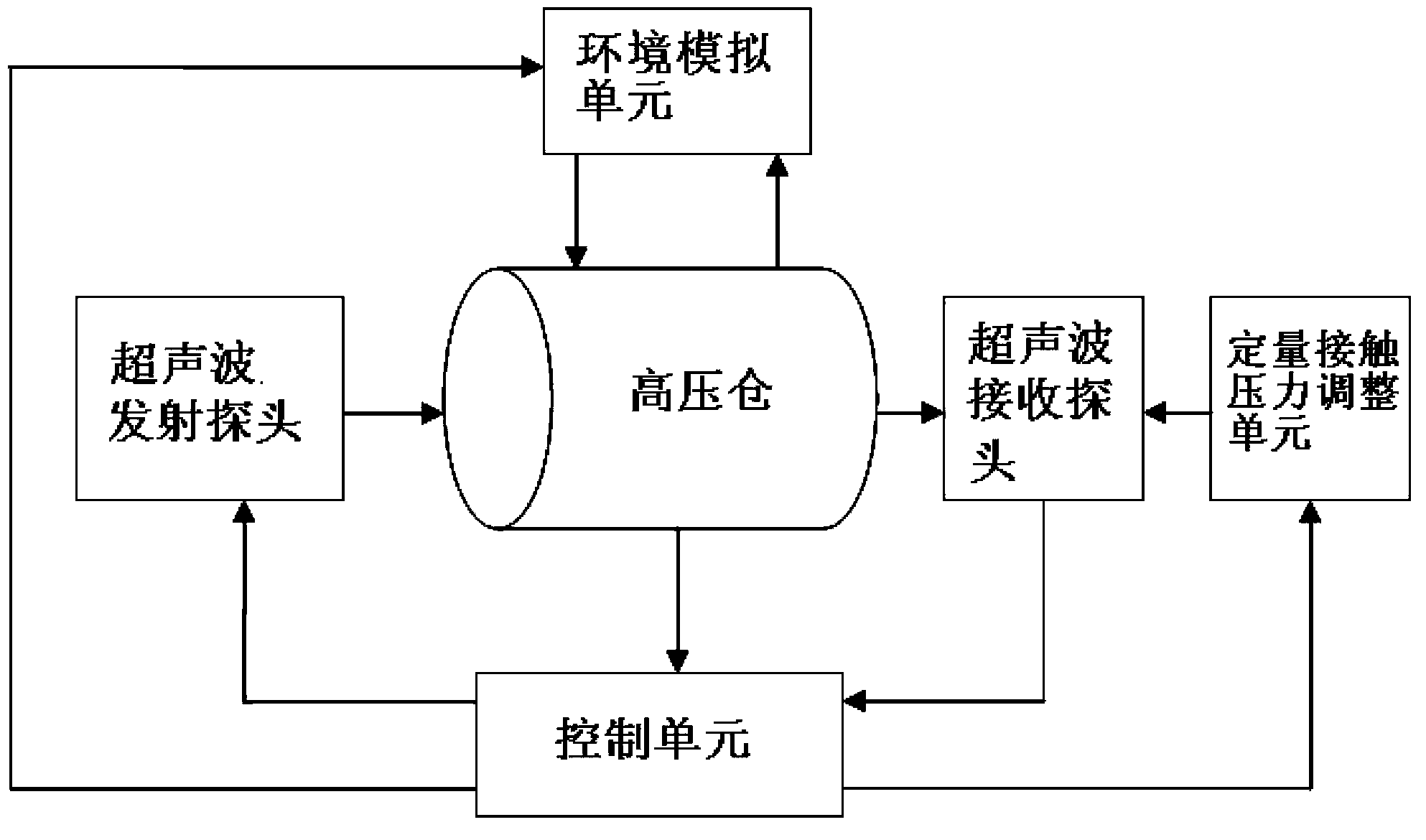

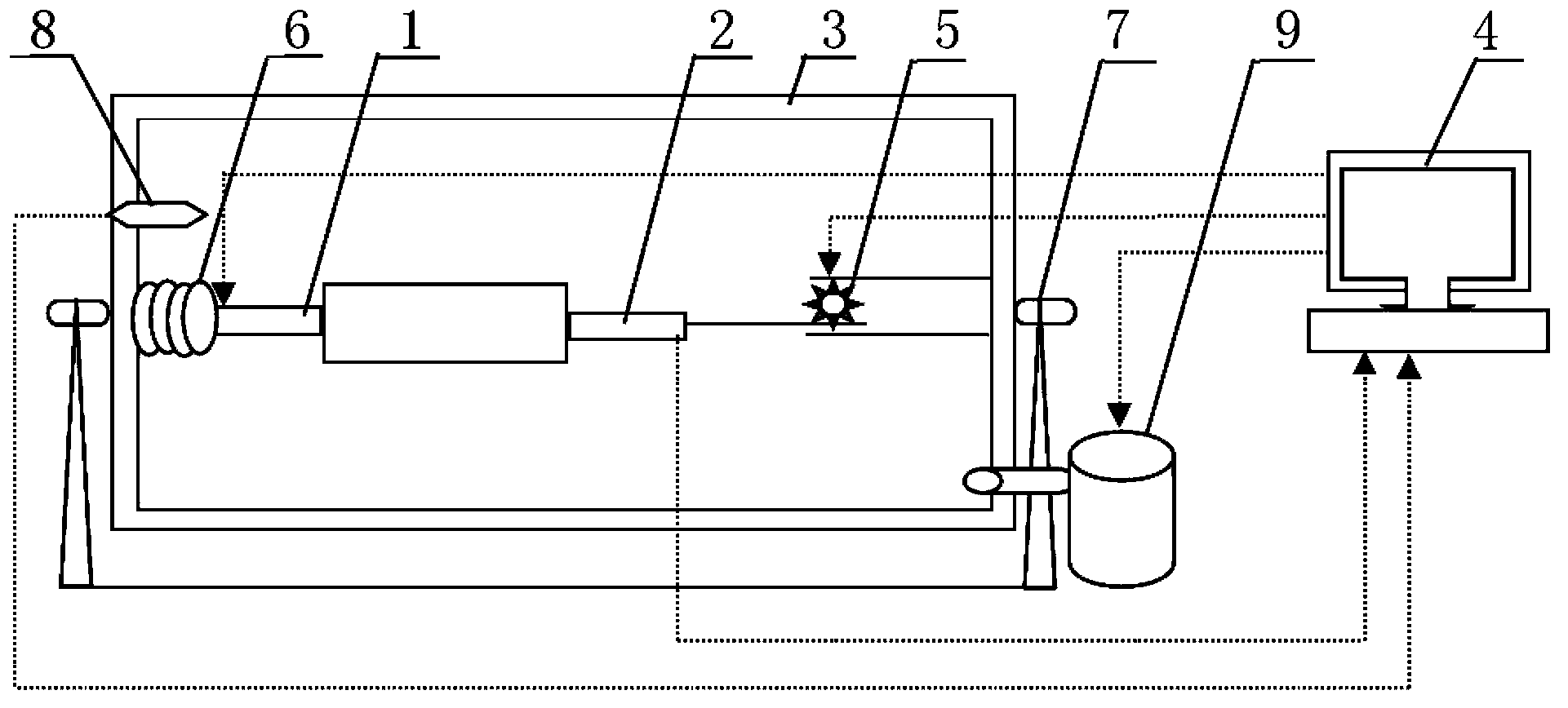

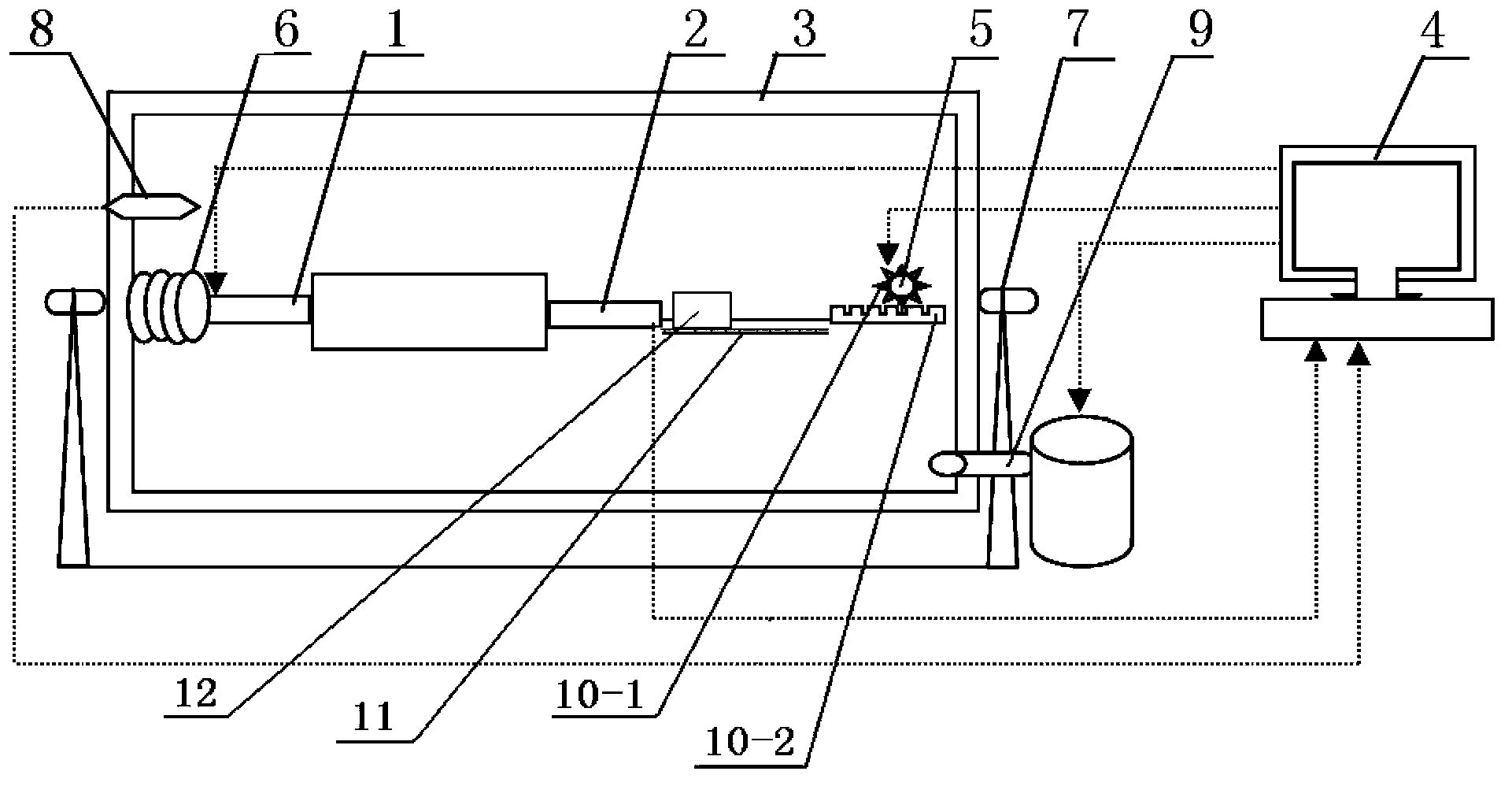

[0053] Such as Figure 1~4 As shown, a quantitative contact pressure ultrasonic detection system includes an ultrasonic transmitting probe 1, an ultrasonic receiving probe 2, a high pressure chamber 3, a computer 4, a quantitative contact pressure adjustment unit, an environment simulation unit and a spring 6;

[0054] The rock sample to be tested is sealed in the high-pressure chamber 3, and the two ends of the high-pressure chamber 3 are fixed on the bracket 7. The outer wall of the high-pressure chamber 3 is made of high-temperature and high-pressure resistant polytetrafluoroethylene.

[0055] The quantitative contact pressure adjustment unit includes a motor and a transmission part; the motor drives the transmission part to connect with the ultrasonic receiving probe 2 for adjusting the ultrasonic receiving probe 2 so that the rock sample to be tested and the ultrasonic receiving probe 2 are connected. Tight coupling between probes 2.

[0056] The transmission part compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com