Acoustic lens composition, ultrasonic probe, and ultrasonic diagnostic apparatus

a technology of ultrasonic probes and compositions, applied in the field of ultrasonic probes and ultrasonic diagnostic apparatuses, can solve the problems of difficult incorporation of this amount of silica powder into silicone rubber, affecting the image quality, and affecting the performance of the acoustic lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

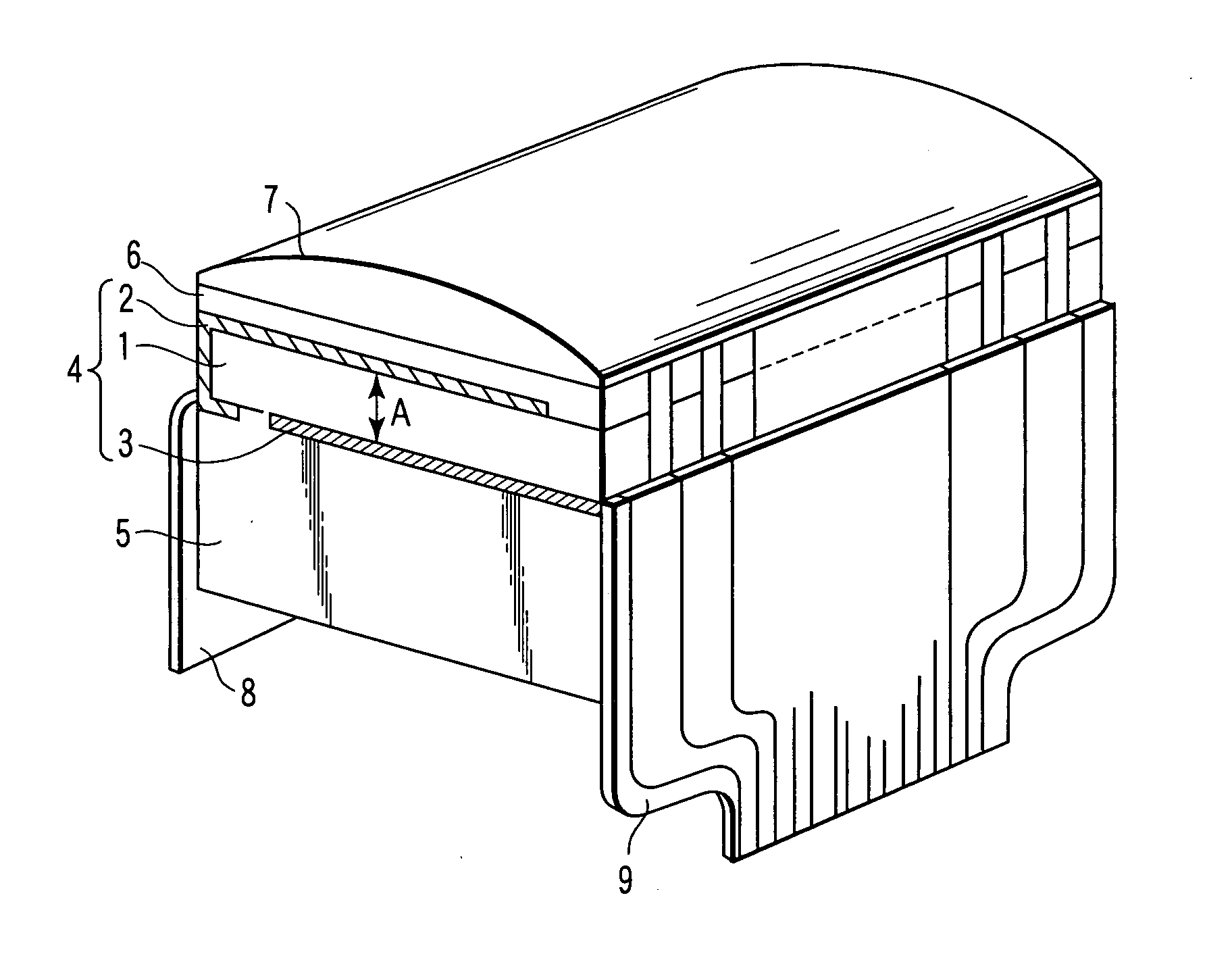

[0056] An acoustic lens composition according to the first embodiment comprises 40 wt % or more of silicone rubber and 15 to 60 wt % of zinc oxide (ZnO).

[0057] The silicone rubber is a material having a siloxane bond, which is an Si—O bond, as a molecular skeleton. For example, as the silicone rubber, a material containing dimethylpolysiloxane as a main component, or the like can be used. The silicone rubber is roughly classified into liquid silicone rubber having a polymerization degree of 100 to 2,000, and millable silicone rubber having a polymerization degree of 3,000 to 10,000.

[0058] The content of the silicone rubber in the acoustic lens composition is 40 wt % or more. If the silicone rubber content is less than 40 wt %, not only the molding properties may deteriorate, but also the attenuation ratio of an ultrasonic wave may increase. In an acoustic lens having the composition, it may also become impossible to obtain a necessary sound velocity or acoustic impedance. The cont...

second embodiment

[0083] An acoustic lens composition according to the second embodiment comprises 40 wt % or more of silicone rubber, and 10 to 52 wt % of at least one platinum-based powder selected from a platinum powder, a platinum powder having platinum oxide on at least the surface, and a platinum oxide powder.

[0084] The silicone rubber is the same as that explained in the first embodiment and also has the same functions as in the first embodiment.

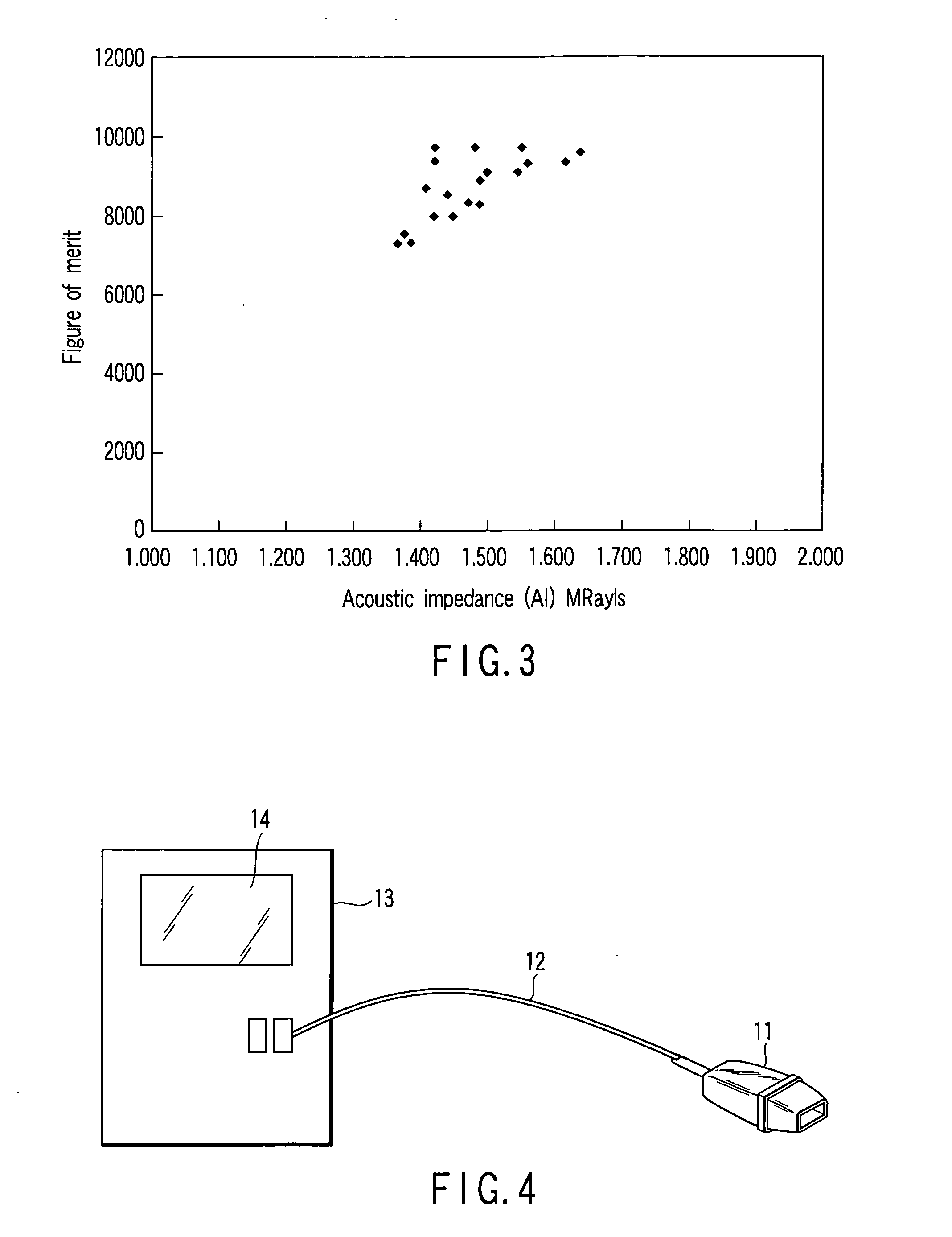

[0085] The content of the platinum-based powder in the acoustic lens composition is 10 to 52 wt %. If the content of the platinum-based powder is less than 10 wt %, it may become difficult to well achieve the effect of lowering the sound velocity of an acoustic lens having the composition, and no appropriate FOM may be obtained. Also, since the density cannot be well increased, it is difficult to set the acoustic lens at a necessary acoustic impedance of about 1.3 to 1.7 MRayls. If the content of the platinum-based powder exceeds 52 wt %, not only th...

third embodiment

[0099] An acoustic lens composition according to the third embodiment comprises 40 wt % or more of silicone rubber, and 12 to 56 wt % of a ytterbium oxide (Yb2O3) powder.

[0100] The silicone rubber is the same as that explained in the first embodiment and also has the same functions as in the first embodiment.

[0101] The content of the ytterbium oxide powder in the acoustic lens composition is 12 to 56 wt %. If the content of the ytterbium oxide powder is less than 12 wt %, it may become difficult to well achieve the effect of lowering the sound velocity of an acoustic lens having the composition, and no appropriate FOM may be obtained. Also, since the density cannot be well increased, it is difficult to set the acoustic lens at a necessary acoustic impedance of about 1.3 to 1.7 MRayls. If the content of the ytterbium oxide powder exceeds 56 wt %, not only the acoustic impedance of the acoustic lens may increase too much, but also the attenuation ratio of an ultrasonic wave may incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sound velocity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com