Microcosmic simulated analysis method for ultrasound attenuation coefficient of composite material with holes

A composite material and attenuation coefficient technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as relatively few studies, inability to accurately establish porous composite material models, etc., to achieve clear thinking and easy to grasp. and the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0027] For convenience and simplification, the present invention makes the following assumptions: 1) The composite material is continuous fibers and the fibers are evenly distributed in the resin, so that the properties of the composite material are uniform and anisotropic except for the pores; 2) The thickness of the composite material in the direction of ultrasonic propagation Uniform; 3) The ideal elastoplastic model is used for simulation calculation.

[0028] Such as figure 1 As shown in the schematic diagram of the work flow, according to the present invention, the simulation analysis method of the ultrasonic attenuation coefficient of the porous carbon fiber reinforced resin matrix composite material based on mesomechanics is mainly realized by two softwares.

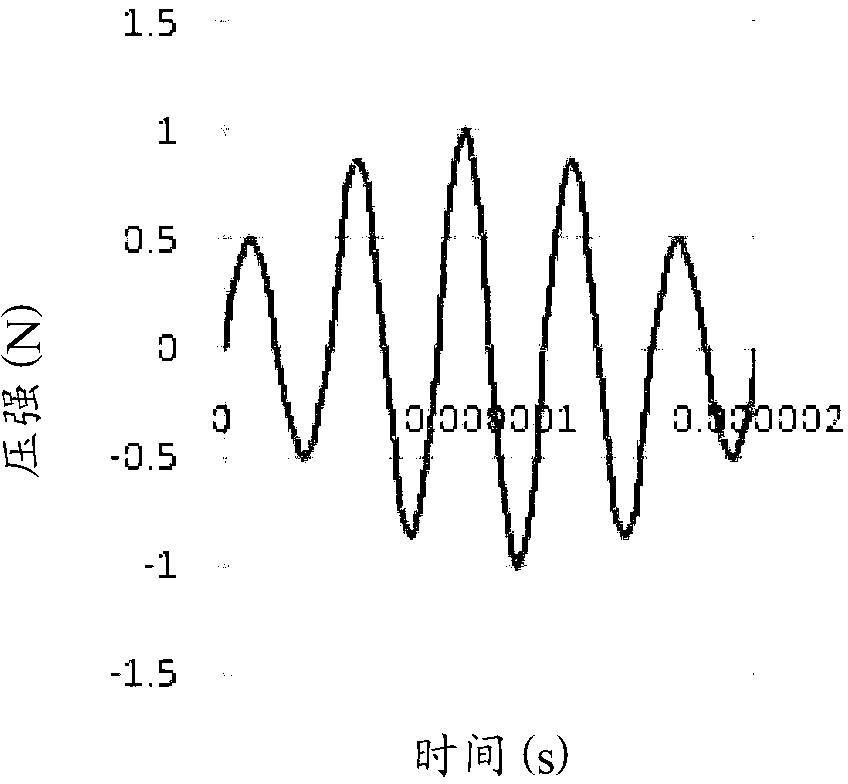

[0029] The detailed steps of the simulation analysis method are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com