Method and device for detecting liquid sample by using ultrasonic atomization and breakdown spectroscopy

A liquid sample, spectral detection technology, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of affecting sensitivity, high cost, high breakdown energy density, and achieve the effect of improving sensitivity and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

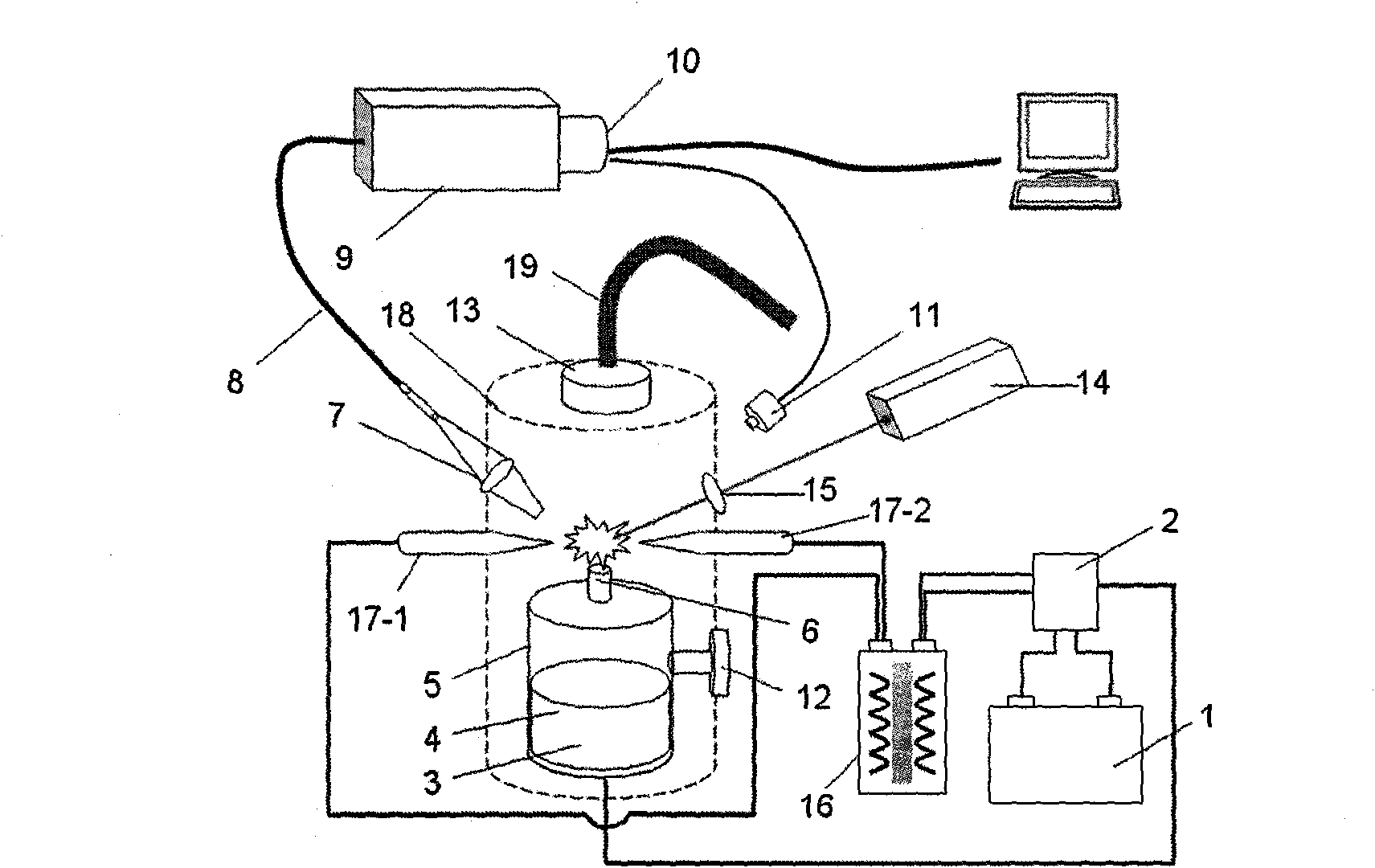

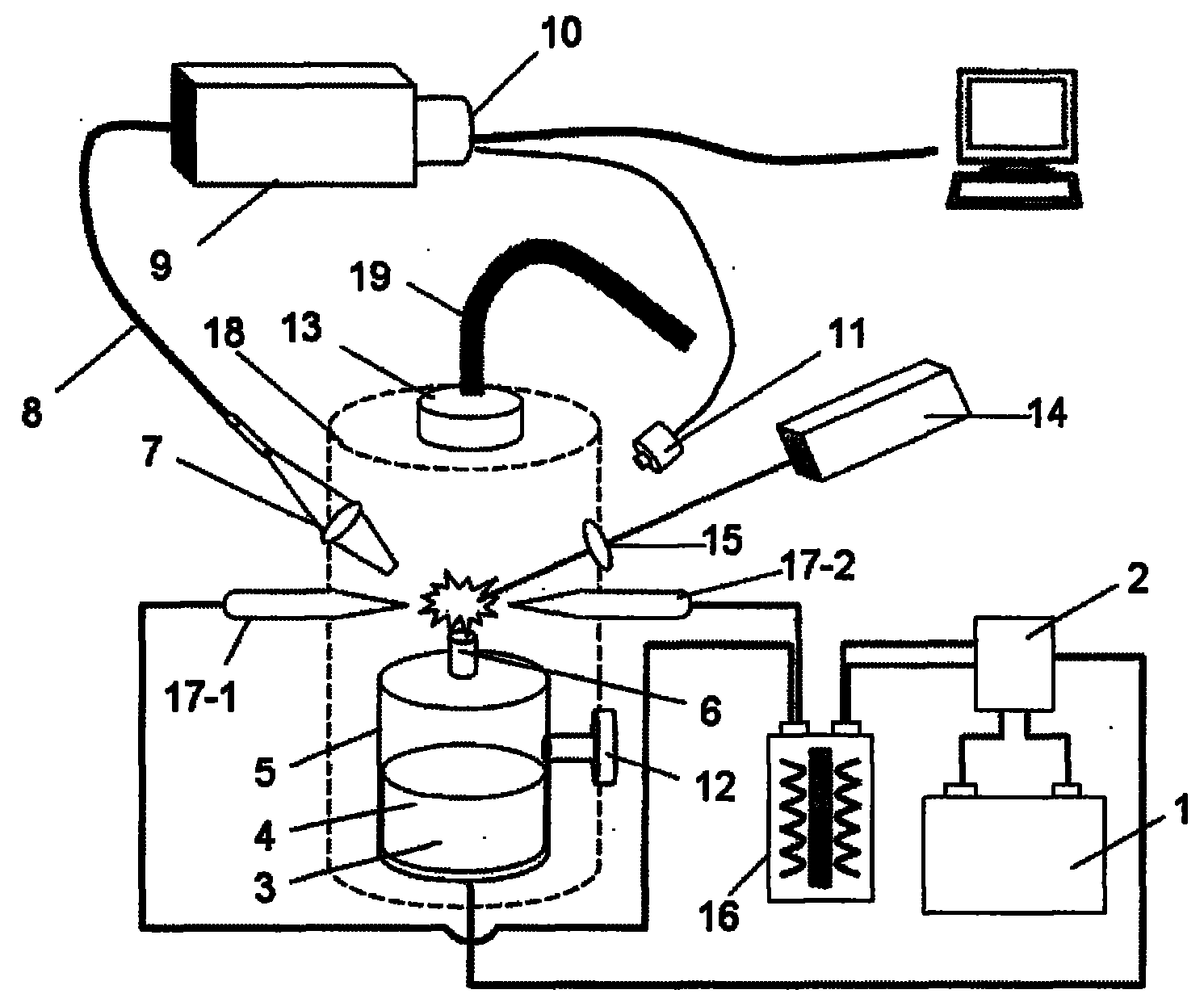

[0010] The present invention is carried out as follows. Put an appropriate amount of the liquid sample to be tested into the sample cell 5 with the ultrasonic transducer 3 installed at the bottom. According to the difference in the viscosity coefficient of the liquid sample 4 to be tested, the output oscillation frequency and output power of the control circuit 2 are adjusted, and the high-frequency oscillation signal is output to the ultrasonic transducer 3 to make it start to work. The working frequency adjustment range of the ultrasonic transducer 3 is between 1MHz and 10MHz. The high-frequency oscillation generated by the ultrasonic transducer 3 will generate a large number of mist droplets with a smaller diameter on the surface of the liquid, and the diameter of the droplets is about 200um. With the assistance of the intake fan 12 and the exhaust fan 13, the air enters the sample cell 5 from the intake fan 12, drives the mist-like liquid droplets to move from bottom to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com