Water immersion ultrasonic flaw detection system and method

A technology of water immersion ultrasonic and ultrasonic probes, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. The needs of the development of flaw detection technology, etc., to improve the system response speed, improve the accuracy and reliability, and achieve the effect of digitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

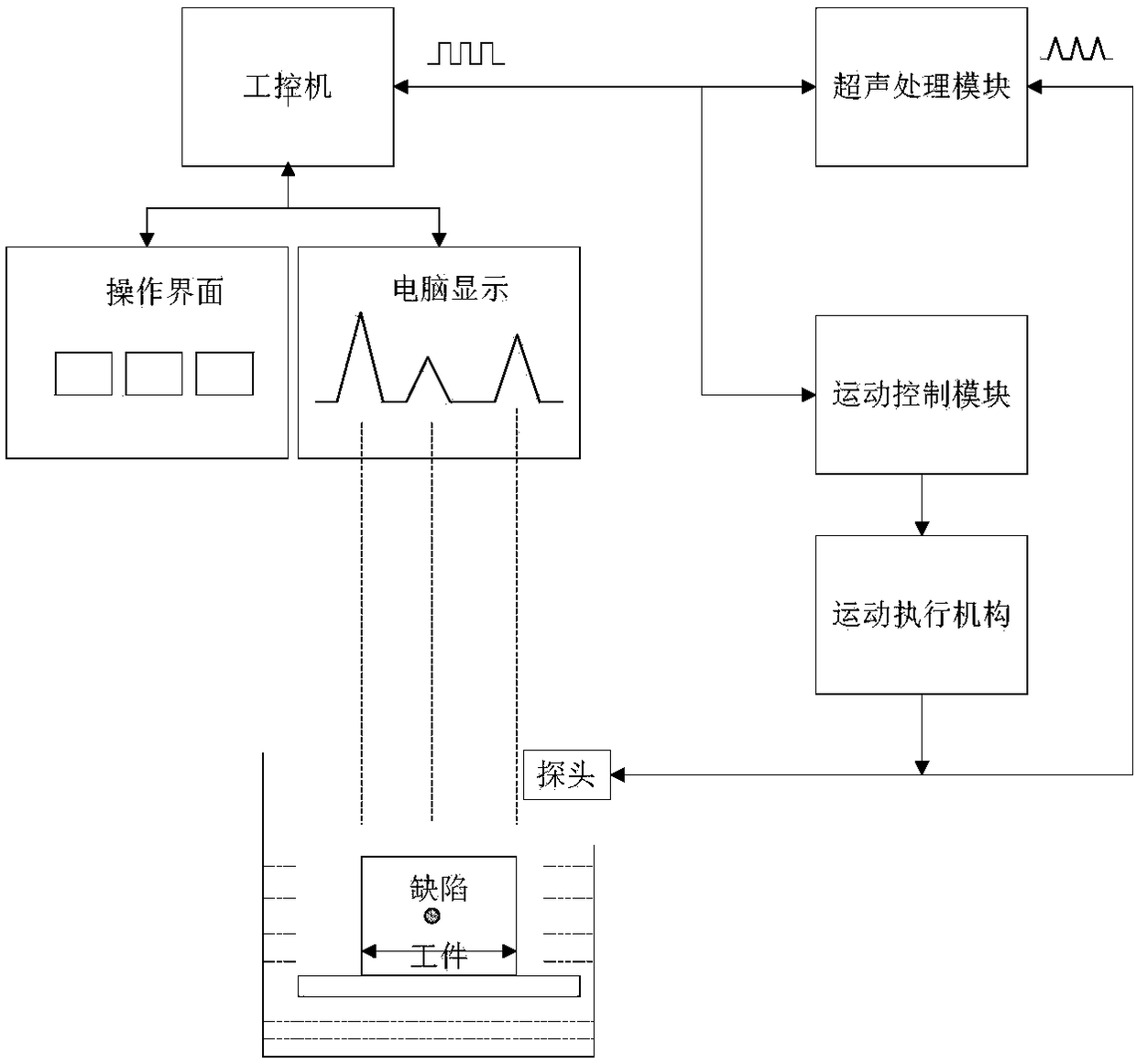

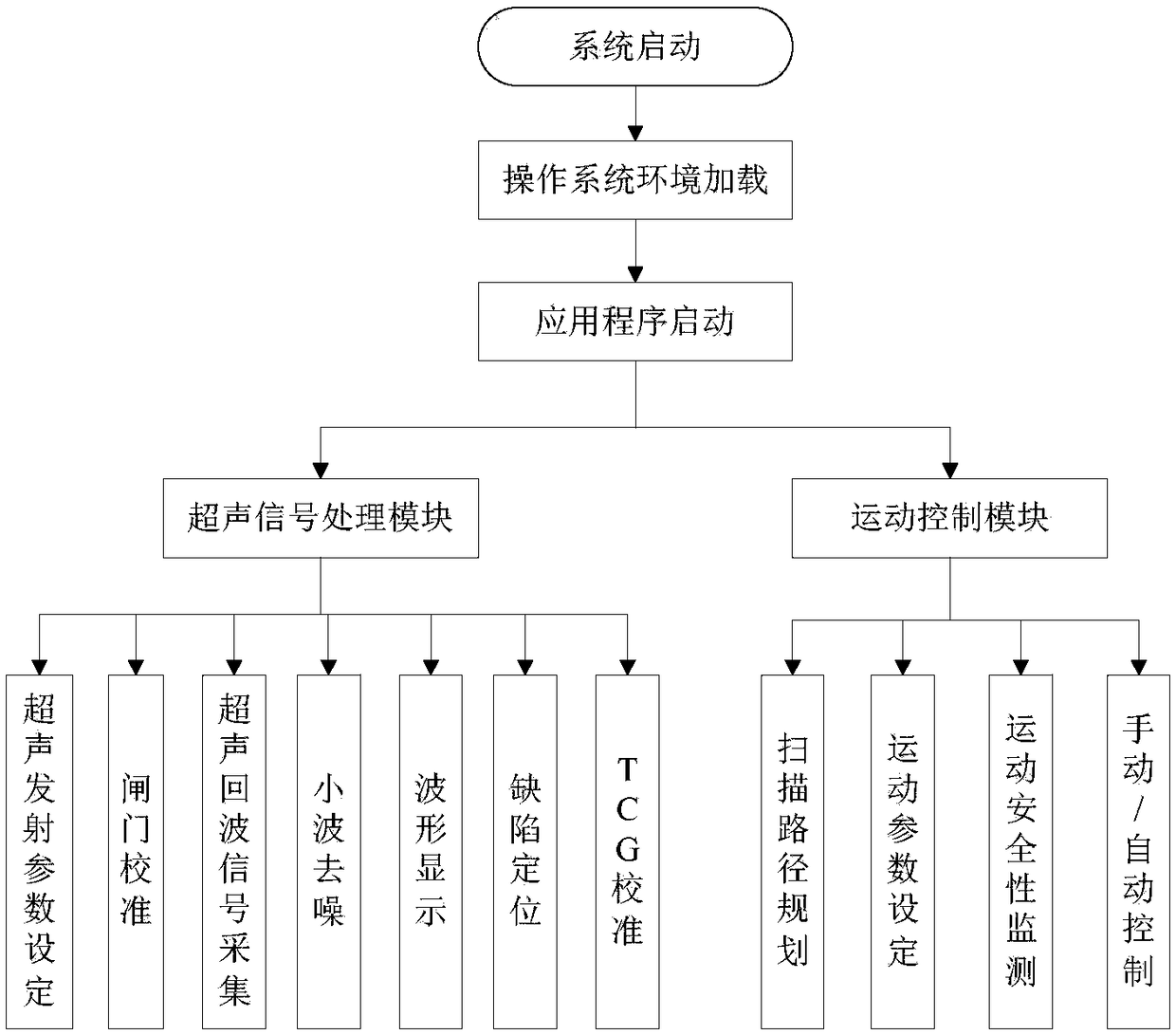

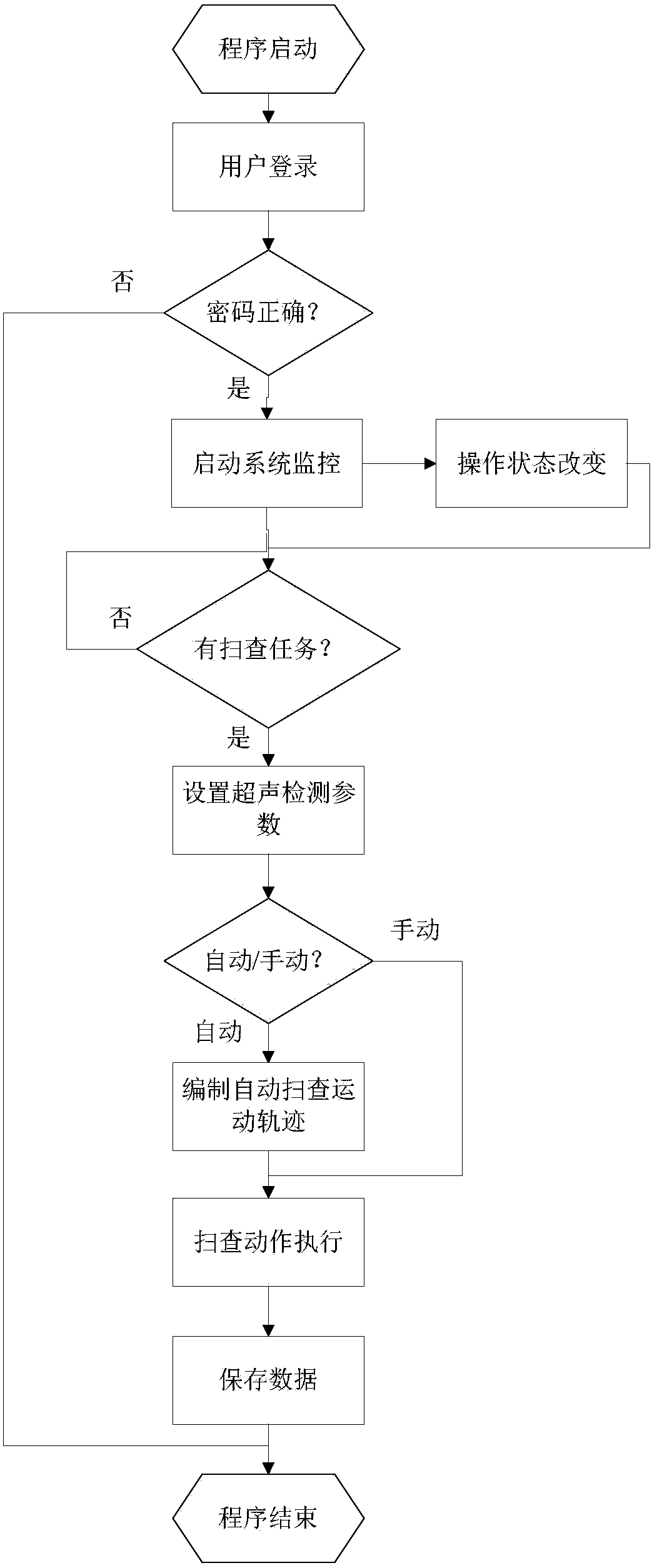

[0049] A method and implementation process of a new type of water immersion ultrasonic flaw detection system is to develop special water immersion ultrasonic operation software on the industrial computer platform, and the software controls the ultrasonic processing module to perform ultrasonic transmission and echo reception through a single crystal longitudinal wave ultrasonic probe, and to receive The received echoes are processed by filtering, wavelet noise reduction, etc. At the same time, the software can also send motion commands to the motion control module to realize the servo control of the speed and position of the 7 motion axes to meet the process inspection requirements of workpieces with different shapes.

[0050] The structure of the water immersion ultrasonic flaw detection system of the present invention is as follows: figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com