Ultrasonic detection defect information acquisition method based on multi-wafer probe

A technology of ultrasonic detection and information collection, applied in the direction of material analysis using acoustic wave emission technology, can solve the problem of limited signal and achieve the effect of improving resolution and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

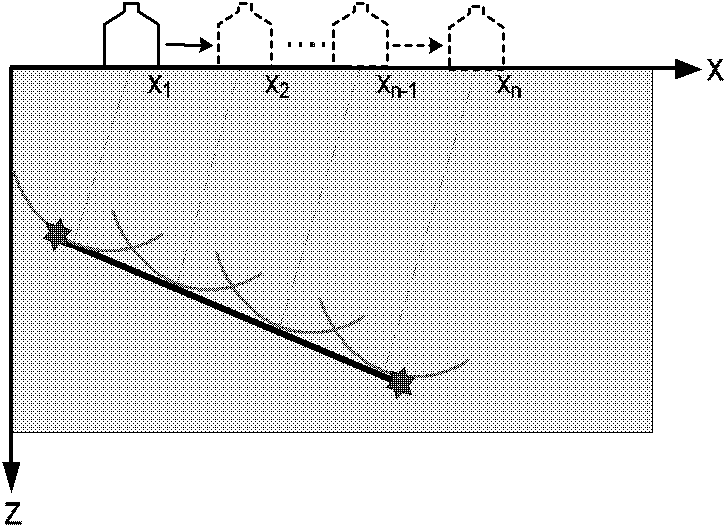

[0023] like image 3 As shown, the defect information collection method of the present invention adopts polycrystalline probes, that is, the probes are evenly distributed and arranged by a plurality of wafers. Each chip has receive and transmit functions. In this embodiment, a plurality of wafers are arranged in a row to form a linear arrangement.

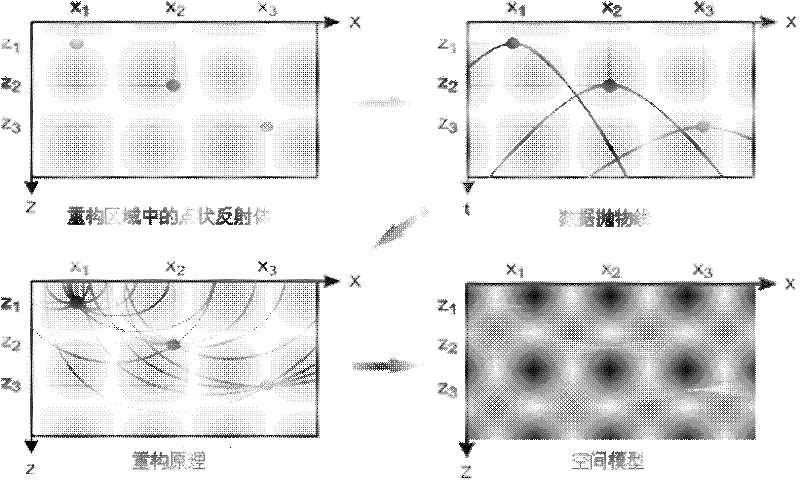

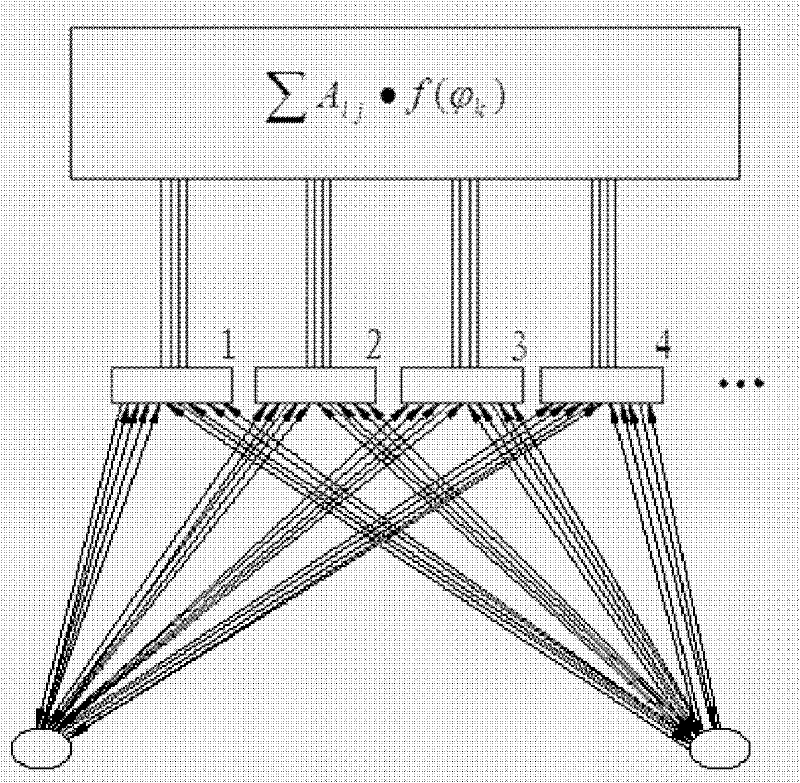

[0024] The probe can form a synthetic aperture, and the image of the plane reflector can be reconstructed through the matrix containing the reflector information. For the sensitivity of the plane reflector, the scanning method is much larger than that of the large-aperture single-crystal probe. The information collected by the probe can be represented by an information data matrix A, as shown in Table 1 below. A ij Indicates the ultrasonic signal received by chip j in the phased array when chip i in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com