Method of preparing high-performance diamond semiconductor based on low-cost single crystal diamond

A single-crystal diamond and low-cost single-crystal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced electrical conductivity, adverse effects of carrier transport properties, roughness, etc., to reduce defect density , Reduce technical difficulty, improve the effect of crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

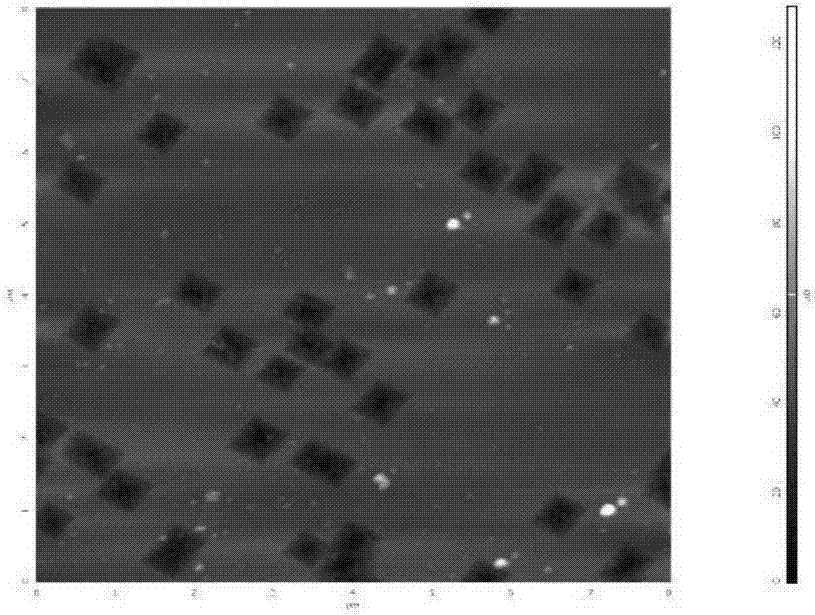

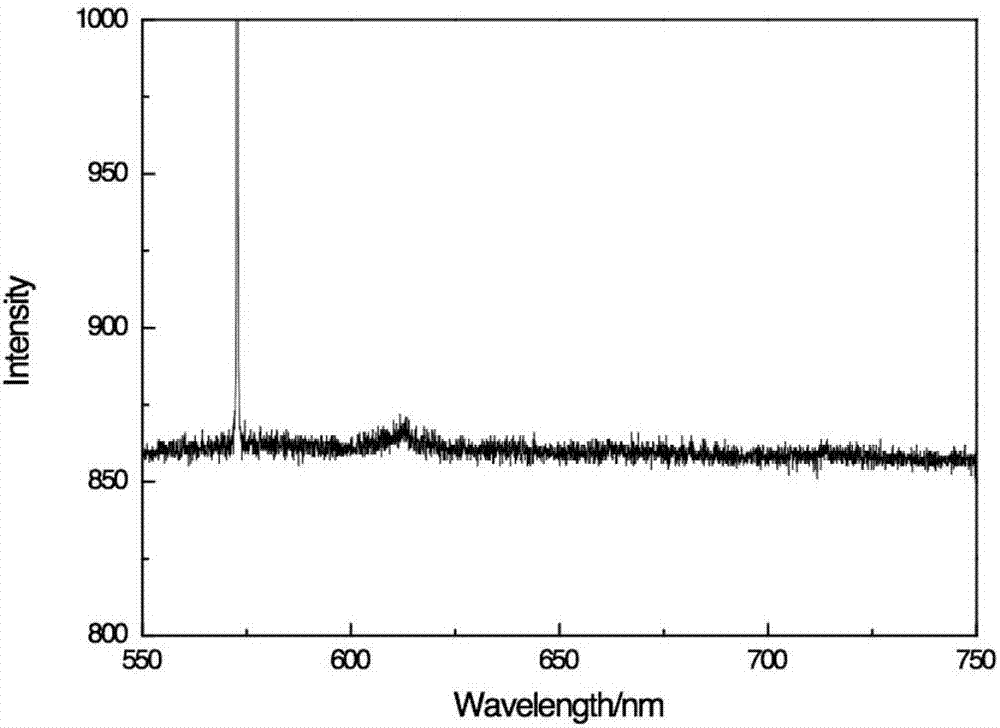

[0040] Using a high temperature and high pressure (100) oriented type Ib single crystal diamond with a side length of 4.3mm and a thickness of 0.8mm as the substrate, the single crystal diamond substrate was cleaned ultrasonically with acetone and alcohol in sequence. The ultrasonic power was 300W. 30min, blow dry. Carry out pickling and passivation treatment on the cleaned diamond substrate, place the diamond substrate in a solution with a sulfuric acid: nitric acid concentration of 5:1, and boil for 30 minutes. The diamond substrate was ultrasonically cleaned with deionized water for 2 times, with an ultrasonic power of 300 W, for 30 min each time, and then dried. The surface-passivated single-crystal diamond substrate was placed in a microwave chemical vapor deposition device, and the surface of the single-crystal diamond substrate was activated by microwave hydrogen plasma at an activation temperature of 800°C and an activation time of 5 minutes. After surface activation ...

Embodiment 2

[0042] Using a high temperature and high pressure (100) oriented type Ib single crystal diamond with a side length of 3.8mm and a thickness of 0.85mm as the substrate, the single crystal diamond substrate was cleaned ultrasonically with acetone and alcohol in sequence. The ultrasonic power was 240W. 30min, blow dry. Carry out pickling and passivation treatment on the cleaned diamond substrate, place the diamond substrate in a solution with a sulfuric acid: nitric acid concentration of 5:1, and boil for 40 minutes. The diamond substrate was ultrasonically cleaned with deionized water for 2 times, with an ultrasonic power of 240W, for 30min each time, and then dried. The surface-passivated single-crystal diamond substrate was placed in a microwave chemical vapor deposition device, and the surface of the single-crystal diamond substrate was activated by microwave hydrogen plasma at an activation temperature of 750°C and an activation time of 10 minutes. After surface activation ...

Embodiment 3

[0044] With the high temperature and high pressure (100) orientation type Ib single crystal diamond with a side length of 8 mm and a thickness of 1 mm as the substrate, the single crystal diamond substrate is cleaned ultrasonically with acetone and alcohol in sequence. The ultrasonic power is 300 W, and each cleaning is 30 minutes. blow dry. Carry out pickling and passivation treatment on the cleaned diamond substrate, place the diamond substrate in a solution with a sulfuric acid: nitric acid concentration of 5:1, and boil for 50 minutes. The diamond substrate was ultrasonically cleaned with deionized water for 2 times, with an ultrasonic power of 300 W, for 30 min each time, and then dried. The surface-passivated single-crystal diamond substrate was placed in a microwave chemical vapor deposition device, and the surface of the single-crystal diamond substrate was activated by microwave hydrogen plasma at an activation temperature of 850°C and an activation time of 3 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com