Vertical graphene/manganese dioxide composite material as well as preparation method and application thereof

A technology of manganese dioxide and composite materials, applied in nanotechnology for materials and surface science, secondary batteries, electrochemical generators, etc., can solve the problems of accelerated reaction rate, poor rate performance, poor conductivity, etc., to achieve Effects of high conductivity, high rate performance, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After the carbon cloth base material is activated with concentrated sulfuric acid, the conditions for the activation of concentrated sulfuric acid are: the temperature is 70°C, the concentration of concentrated sulfuric acid is 5mol / L, and the activation time is 120 minutes, and then it is washed several times with deionized water and ethanol to obtain the preliminary Treated carbon cloth substrate.

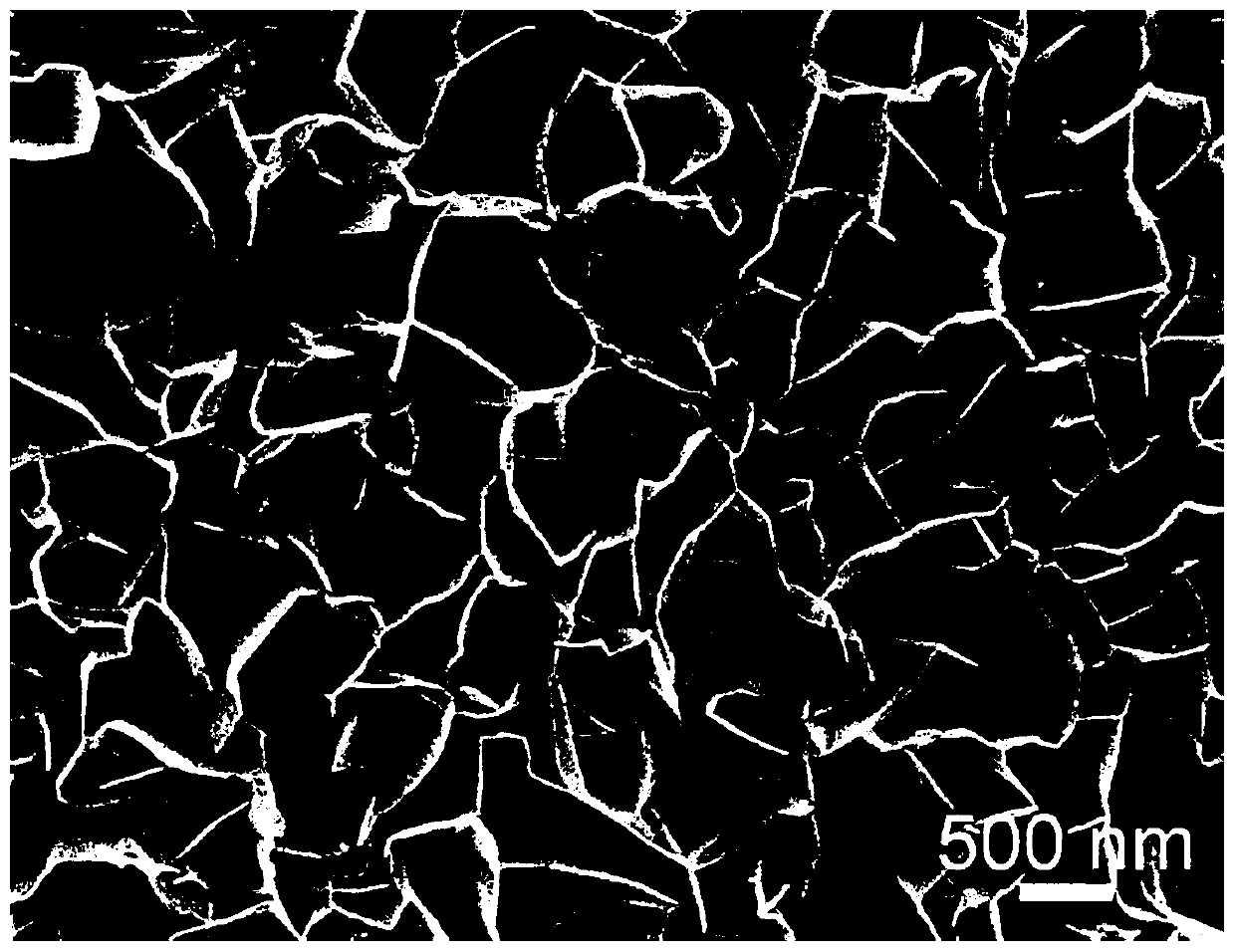

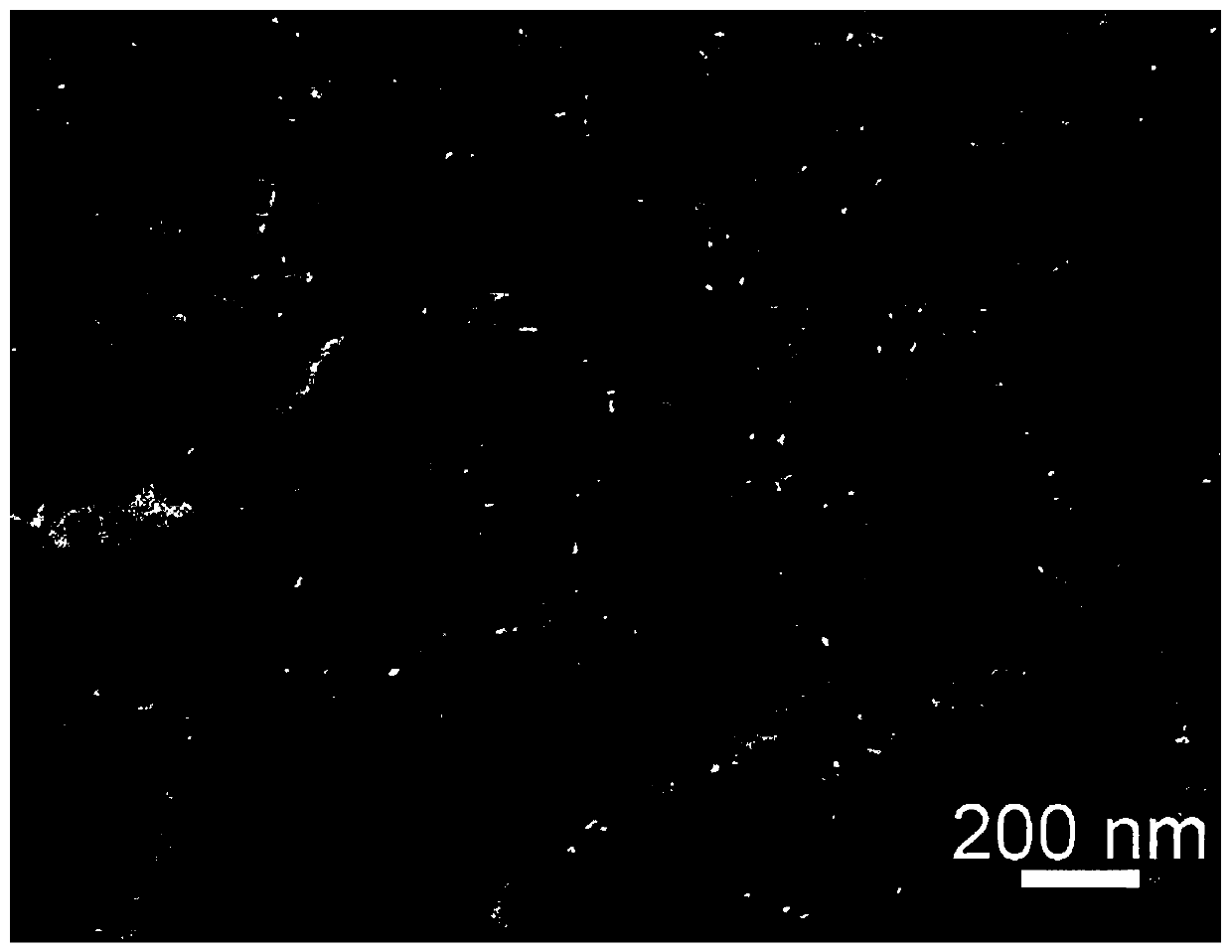

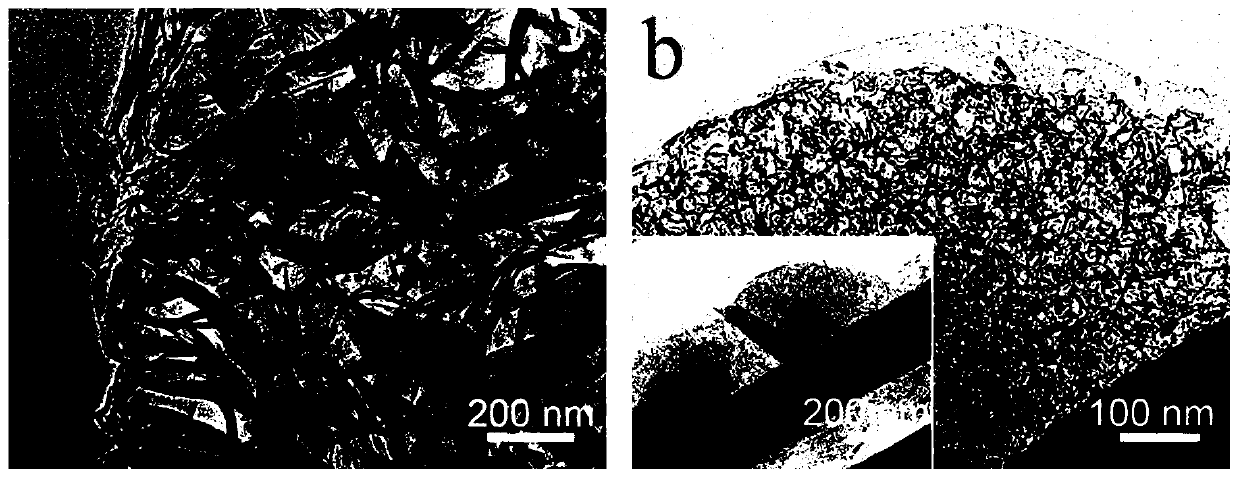

[0026] The pretreated carbon cloth substrate was placed in a tube furnace and evacuated so that the system pressure reached 10 mTorr. Then the temperature was raised to 450°C, and plasma was generated when the microwave power reached 550W under hydrogen atmosphere. After the carbon cloth was treated with plasma, it was heated to 750°C for 1 hour under the atmosphere of methane and hydrogen (volume ratio: 5:1), and the vertical graphene material grown on the carbon cloth substrate was obtained. Scanning electron microscope (SEM) and transmission electron microscope (TEM) a...

Embodiment 2

[0029] After the carbon cloth base material is activated with concentrated sulfuric acid, the conditions for the activation of concentrated sulfuric acid are: the temperature is 80°C, the concentration of concentrated sulfuric acid is 8mol / L, and the activation time is 90 minutes, and then it is washed several times with deionized water and ethanol to obtain the preliminary Treated carbon cloth substrate.

[0030] The pretreated carbon cloth substrate was placed in a tube furnace and evacuated so that the system pressure reached 10 mTorr. Then the temperature was raised to 500°C, and plasma was generated when the microwave power reached 600W under hydrogen atmosphere. After the carbon cloth was treated with plasma, the temperature was raised to 800°C for 1.5 hours under the atmosphere of methane and hydrogen (10:1 volume ratio), and the vertical graphene material grown on the carbon cloth substrate was obtained.

[0031] Weigh 7.9g of potassium permanganate and dissolve it in...

Embodiment 3

[0033] After the carbon cloth base material is activated with concentrated sulfuric acid, the conditions for the activation of concentrated sulfuric acid are: the temperature is 90°C, the concentration of concentrated sulfuric acid is 10mol / L, the activation time is 60 minutes, and then washed several times with deionized water and ethanol to obtain the pre- Treated carbon cloth substrate.

[0034]The pretreated carbon cloth substrate was placed in a tube furnace and evacuated so that the system pressure reached 10 mTorr. Then the temperature was raised to 550°C, and plasma was generated when the microwave power reached 650W under hydrogen atmosphere. After the carbon cloth was treated with plasma, the temperature was raised to 850°C for 2 hours under the atmosphere of methane and hydrogen (15:1 volume ratio), and the vertical graphene material grown on the carbon cloth substrate was obtained.

[0035] Weigh 15.8g of potassium permanganate and dissolve it in 1000ml of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com