Method for preparation of large size CVD diamond by vertical splicing and cutting

A cutting method and diamond technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems such as diamond separation, achieve the effect of breaking through size bottlenecks and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

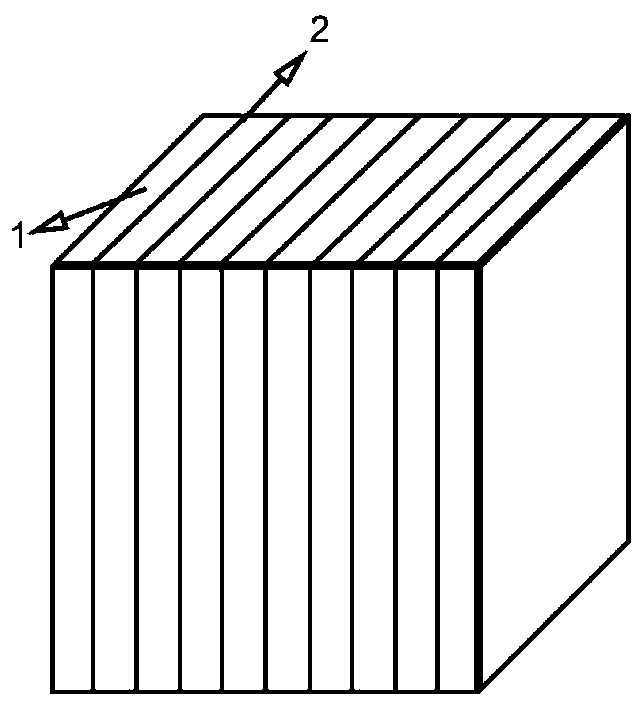

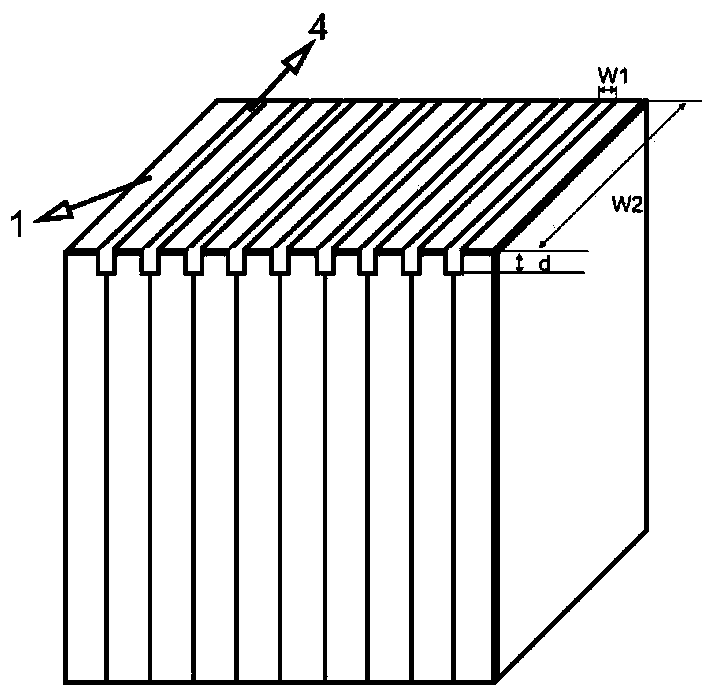

[0036] Select 10 single crystal diamonds with a side orientation of (100), each with a size of 4×4×1mm 3 , arrange 10 seed crystals vertically and closely, such as figure 1 shown. The upper surface of its composition is mechanically polished at the same time, and the seed crystals to be spliced are placed vertically and closely together, and placed on the same workpiece, so that all the seed crystals can be polished under the same process conditions, ensuring the upper surface. It has the same height and roughness after polishing. First use a load of 200 for 5 minutes, then increase the load to 600, and polish for 10 minutes. Finally, use a load of 300 and polish for 10 minutes. For comparison, the polished sample was acid-washed for 30 minutes, and then ultrasonically cleaned with acetone and absolute ethanol for 10 minutes; the laser was used for groove processing, such as figure 2 As shown, size W1=50μm, W2=4000μm, d=50μm, set laser power 1KW, laser step length 5mm / s;...

Embodiment 2

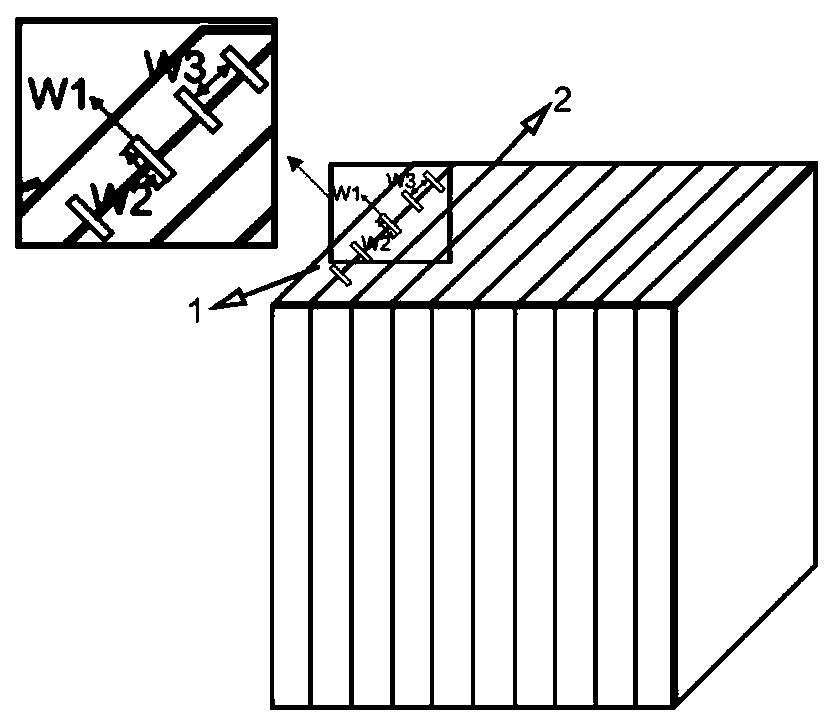

[0038] Select 15 single crystal diamonds with a side orientation of (110), each with a size of 8×8×1mm 3 , arrange 15 seed crystals vertically and closely, such as figure 1 shown. The upper surface of its composition is mechanically polished at the same time, and the seed crystals to be spliced are placed vertically and closely together, and placed on the same workpiece, so that all the seed crystals can be polished under the same process conditions, ensuring the upper surface. It has the same height and roughness after polishing. First use a load of 300 for 5 minutes, then increase the load to 800, and polish for 10 minutes. Finally, use a load of 300 and polish for 10 minutes. For comparison, the polished sample was pickled for 40 minutes, and then ultrasonically cleaned with acetone and absolute ethanol for 10 minutes respectively; using a laser for groove processing, it is necessary to make a periodic microgrooves, such as image 3 As shown, size W1=100μm, W2=500μm, ...

Embodiment 3

[0040] Select 20 single crystal diamonds with a side orientation of (100), each with a size of 10×10×1mm 3 , arrange 20 seed crystals vertically and closely, such as figure 1 shown. The upper surface of its composition is mechanically polished at the same time, and the seed crystals to be spliced are placed vertically and closely together, and placed on the same workpiece, so that all the seed crystals can be polished under the same process conditions, ensuring the upper surface. It has the same height and roughness after polishing. First use a load of 300 for 5 minutes, then increase the load to 800, and polish for 10 minutes. Finally, use a load of 300 and polish for 10 minutes. For comparison, the polished sample was acid-washed for 40 minutes, and then ultrasonically cleaned with acetone and absolute ethanol for 20 minutes respectively; the laser was used for groove processing, such as figure 2 As shown, the size W1=150μm, W2=10000μm, d=50μm, set the laser power to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com