Method for growing polycrystalline diamond piece by using microwave plasma chemical vapor deposition method

A chemical vapor deposition and microwave plasma technology is applied in the field of synthetic diamond to achieve the effect of increasing the density and refining the diamond particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

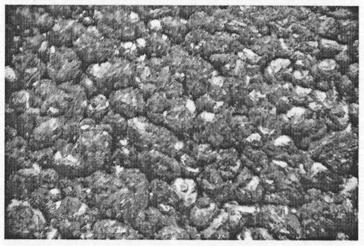

Image

Examples

Embodiment 1

[0030] In the embodiment of the present invention, the method for growing polycrystalline diamond chips by microwave plasma chemical vapor deposition has the following specific steps:

[0031] (1) Pretreating the substrate in the microwave plasma chemical vapor deposition equipment;

[0032] (2) Nucleation for 0.5h on the pretreated substrate according to the conventional polycrystalline diamond sheet growth process;

[0033] (3) Long-term growth of polycrystalline diamond chips under the condition of fixed methane, hydrogen and other added gases, the growth temperature is controlled at 800-1050°C, and the growth time is controlled at 40 hours;

[0034] (4) After 40 hours of growth, stop the supply of other gases except hydrogen, use the plasma generated by hydrogen to etch the diamond chip sample in the reaction chamber for 1 hour, and then slowly reduce the microwave power in the microwave plasma chemical vapor deposition equipment , And gradually stop the supply of hydrogen to redu...

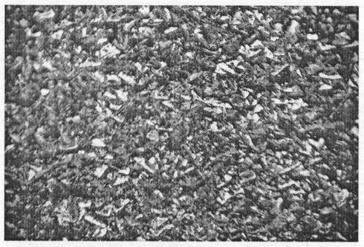

Embodiment 2

[0044] In the embodiment of the present invention, the method for growing polycrystalline diamond chips by microwave plasma chemical vapor deposition has the following specific steps:

[0045] (1) Pretreating the substrate in the microwave plasma chemical vapor deposition equipment;

[0046] (2) Nucleation for 0.5h on the pretreated substrate according to the conventional polycrystalline diamond sheet growth process;

[0047] (3) Long-term growth of polycrystalline diamond chips under the conditions of fixed methane, hydrogen and other added gases, the growth temperature is controlled at 800-1050°C, and the growth time is controlled at 24 hours;

[0048] (4) After 24 hours of growth, stop the supply of other gases except hydrogen, use the plasma generated by hydrogen to etch the diamond chip sample in the reaction chamber for 1 hour, and then slowly reduce the microwave power in the microwave plasma chemical vapor deposition equipment , And gradually stop the hydrogen supply to reduce...

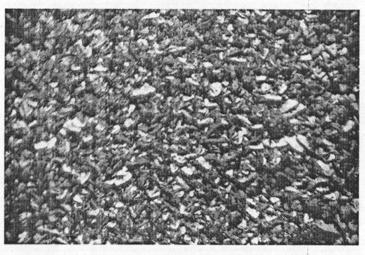

Embodiment 3

[0059] In the embodiment of the present invention, the method for growing polycrystalline diamond chips by microwave plasma chemical vapor deposition has the following specific steps:

[0060] (1) Pretreating the substrate in the microwave plasma chemical vapor deposition equipment;

[0061] (2) Nucleation for 0.5h on the pretreated substrate according to the conventional polycrystalline diamond sheet growth process;

[0062] (3) Long-term growth of polycrystalline diamond chips under the conditions of fixed methane, hydrogen and other added gases, the growth temperature is controlled at 800-1050°C, and the growth time is controlled at 24 hours;

[0063] (4) After 24 hours of growth, stop the supply of other gases except hydrogen, use the plasma generated by hydrogen to etch the diamond chip sample in the reaction chamber for 1 hour, and then slowly reduce the microwave power in the microwave plasma chemical vapor deposition equipment , And gradually stop the hydrogen supply to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com