Chemical vapor deposition method for preparing diamond single crystal by adding N2O gas

A chemical vapor deposition and diamond single crystal technology, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems affecting the quality of diamond single crystals and deepening the color of single crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

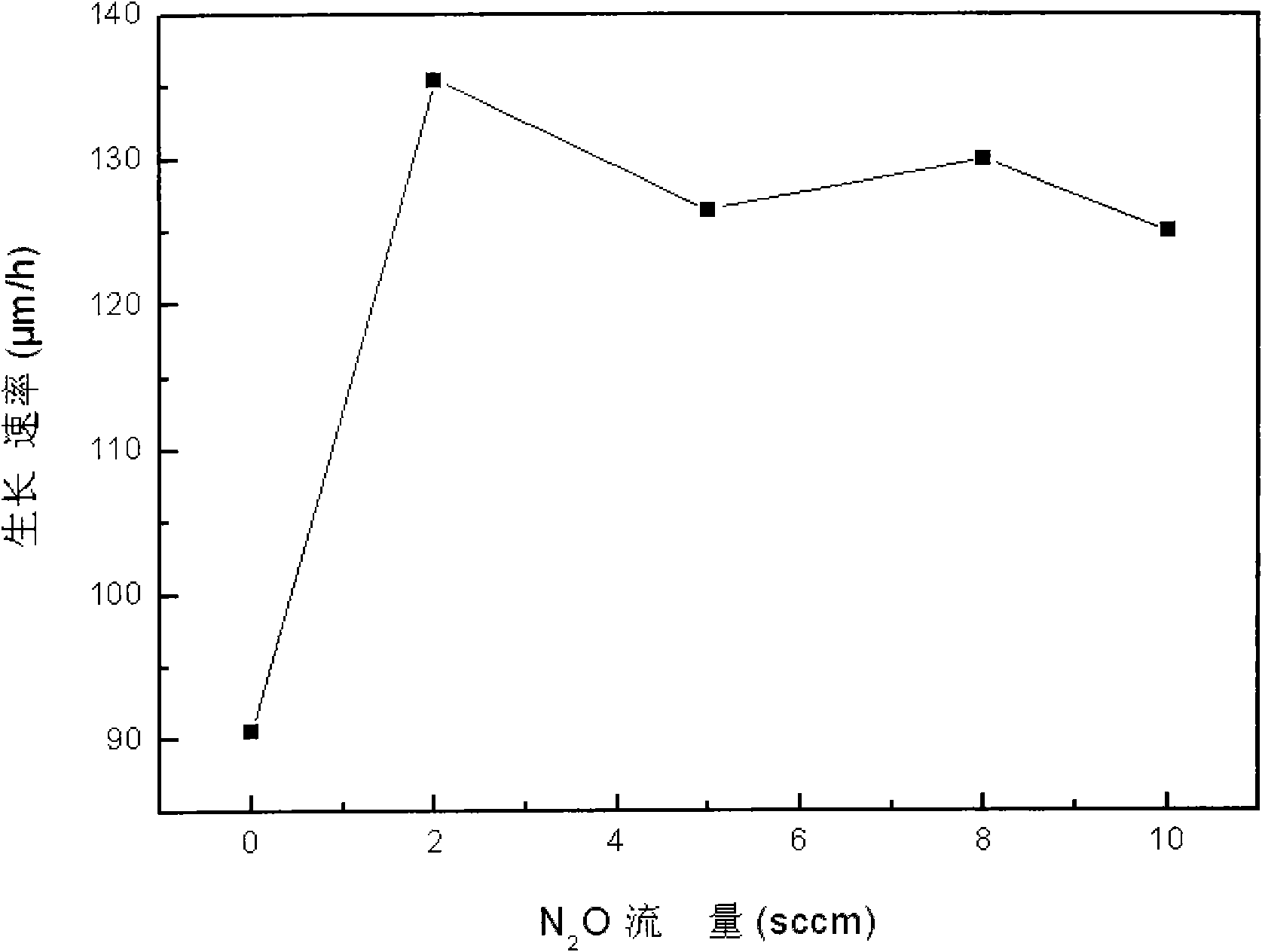

Embodiment 1

[0020] The ASTex 5250 type 5kw (2.45GHz) microwave plasma chemical vapor deposition equipment of Seki Company is used, and the high temperature and high pressure type Ib single crystal (100) diamond is used as the substrate, and the single crystal diamond is grown at a high speed by homoepitaxial growth. The upper and lower (100) sides of the single crystal diamond substrate are mechanically polished, then ultrasonically cleaned in acetone, and finally placed in a polycrystalline diamond-like crystal holder and placed in a deposition chamber. First pump down the pressure in the deposition chamber to below 0.1Pa. The gases used in the experiment are high-purity methane (purity 99.99%), hydrogen (purity 99.999%) and laughing gas (purity 99.999%). In the growth stage, hydrogen, methane and nitrous oxide were fed, and the flow rates were 750, 75, and 2 sccm respectively; the growth was carried out for 2 hours under the conditions of a pressure of 13 kPa and a microwave power of 2....

Embodiment 2

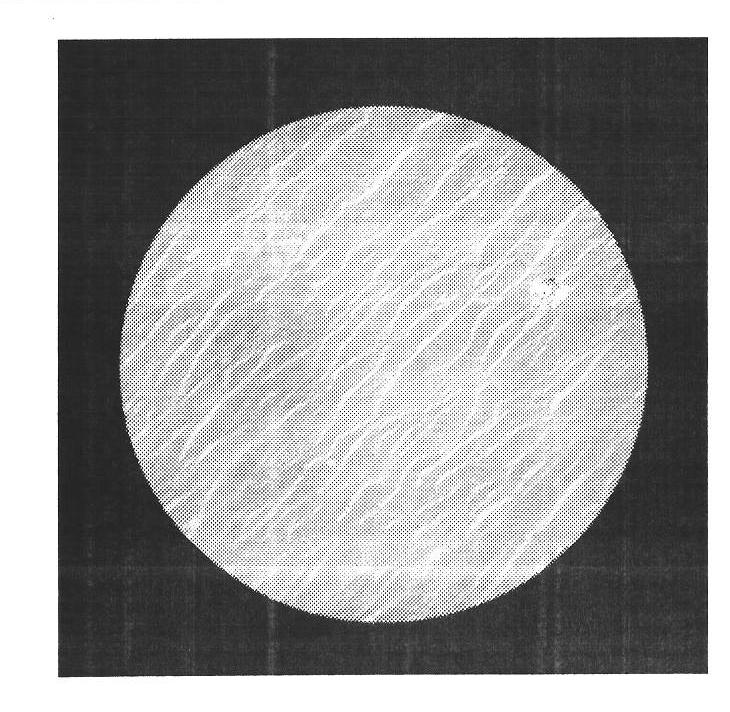

[0022] The deposition system is the same as in Example 1. In the growth stage, hydrogen, methane and nitrous oxide were introduced, and the flow rates were 750, 90, and 2 sccm respectively; the growth was carried out for 2 hours under the conditions of a pressure of 40 kPa and a microwave power of 2.0 kw. The temperature of the substrate in the growth stage was measured to be 1000° C. by an infrared thermometer (IR-GZ01N type produced by CHINO Corporation, Japan). The color of the obtained single crystal is yellow, the surface has a slight orange-peel-like texture, which is relatively smooth, and the growth rate is 135 μm / h.

Embodiment 3

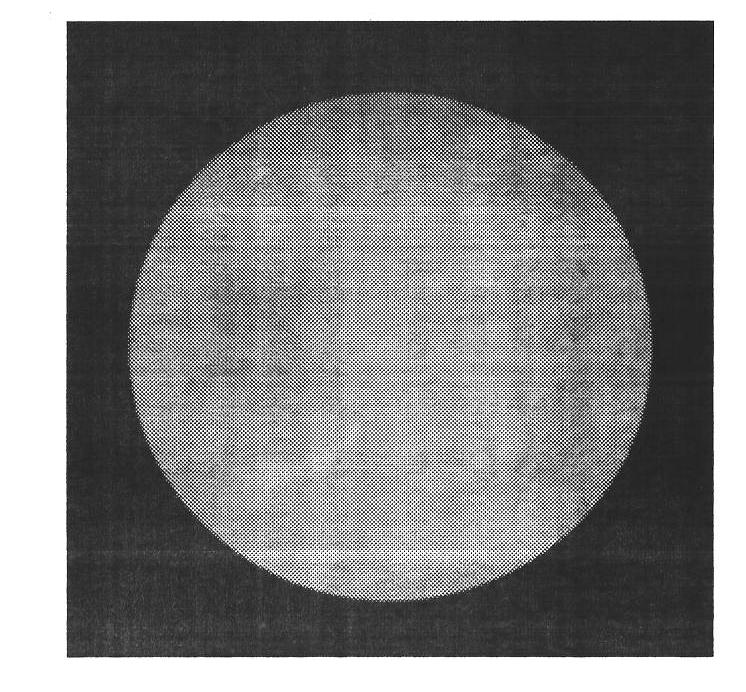

[0024] The deposition system is the same as in Example 1. In the growth stage, hydrogen, methane and nitrous oxide were introduced, and the flow rates were 750, 90, and 5 sccm respectively; the growth was carried out for 2 hours under the conditions of a pressure of 40 kPa and a microwave power of 2.0 kw. The temperature of the substrate in the growth stage was measured to be 1000° C. by an infrared thermometer (IR-GZ01N type produced by CHINO Corporation, Japan). The color of the obtained single crystal is light yellow, the surface is smooth, and the growth rate is 125 μm / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com