Preparation method of high-performance lithium ion battery based on three-dimensional graphene bracket structure

A lithium-ion battery and support structure technology, which is applied in the direction of electrolyte storage battery manufacturing, electrode manufacturing, secondary batteries, etc., can solve the problems of reducing internal stress, achieve stress relief, simple and convenient operation, and avoid the effect of coating film preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention relates to a kind of high-performance ion battery preparation method based on three-dimensional graphene support structure, and described preparation method is as follows:

[0029] Step 1: Clean the nickel sheet, copper sheet or nickel-copper alloy sheet ultrasonically with acetone, alcohol, and deionized water for 5-15 minutes respectively. After drying, put it into a 1.5kW microwave plasma chemical vapor deposition chamber and heat it to After 600-700 degrees, add 1100-1400 watts of microwave power, and at the same time feed 1-2sccm methane, keep the pressure at 20-30Torr, and treat with hydrogen plasma for 10-30 minutes. After the treatment, turn off the plasma and let the chamber Natural cooling to form a three-dimensional graphene scaffold;

[0030] Step 2: Take the three-dimensional graphene support out of the microwave plasma chemical vapor deposition chamber, put it into the magnetron sputtering chamber, use the lithium-ion battery electrod...

Embodiment 1

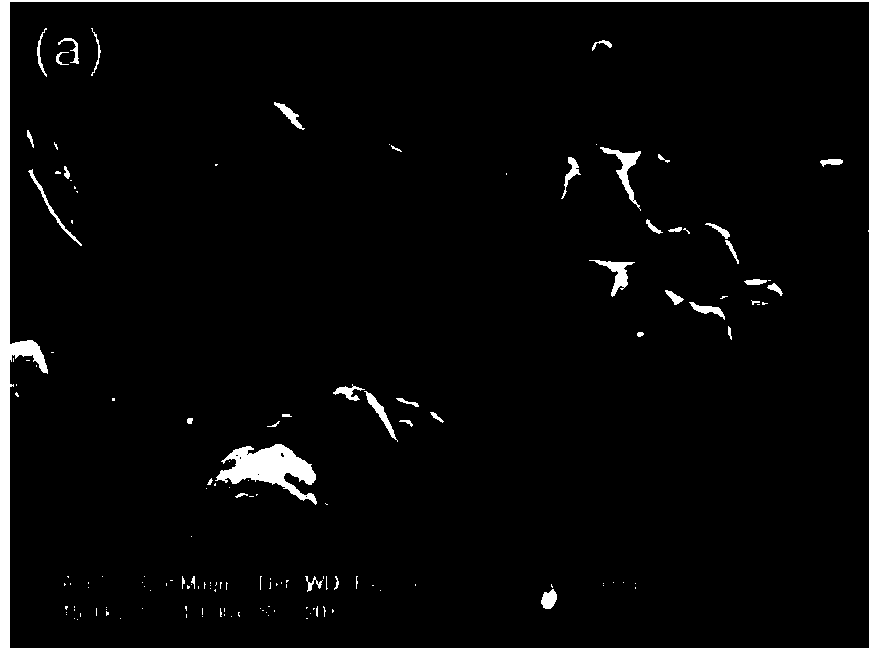

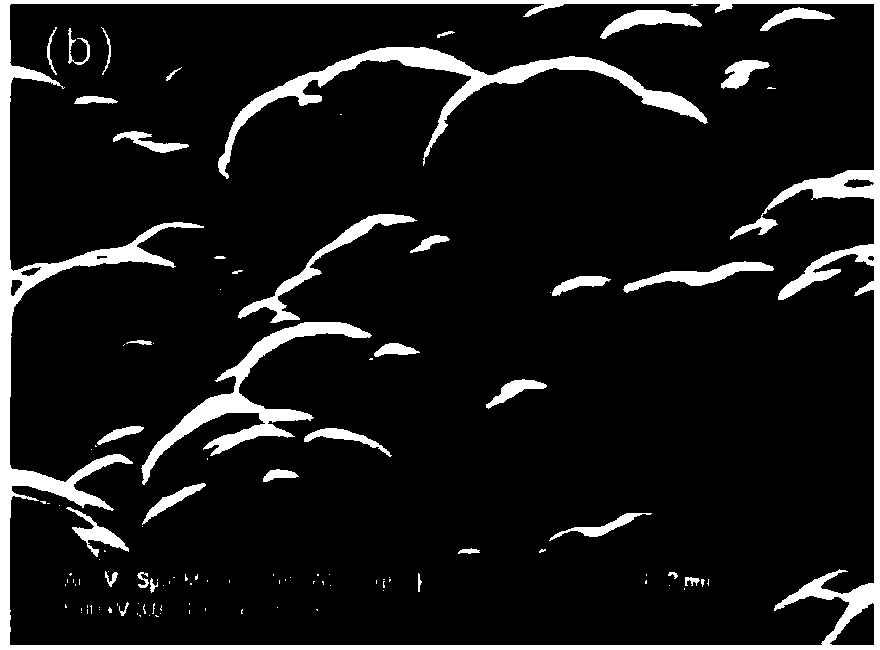

[0035]Embodiment 1 Put the nickel sheet through the standard cleaning into a 1.5kW ASTeX plasma-enhanced chemical vapor deposition system cavity, feed 100 sccm hydrogen, add 1200 watts of microwave power when the temperature increases to 650 degrees, and feed 1.5 sccm methane simultaneously, After 20 minutes of plasma treatment, turn off the microwave, let the cavity cool naturally, take out the sample, and use SEM to observe the three-dimensional graphene structure growing on the surface of the nickel sheet. Then put the three-dimensional graphene-nickel sheet into the magnetron sputtering chamber, pass in 10 sccm of argon gas to control the pressure at 2mTorr, add 50W RF power, sputter for 30 minutes, and then a layer will be covered on the surface of the three-dimensional graphene A silicon film of about 1 μm.

[0036] Afterwards, the silicon-three-dimensional graphene-nickel sheet was assembled in an argon glove box, in which porous polypropylene was used as a separator, a...

Embodiment 2

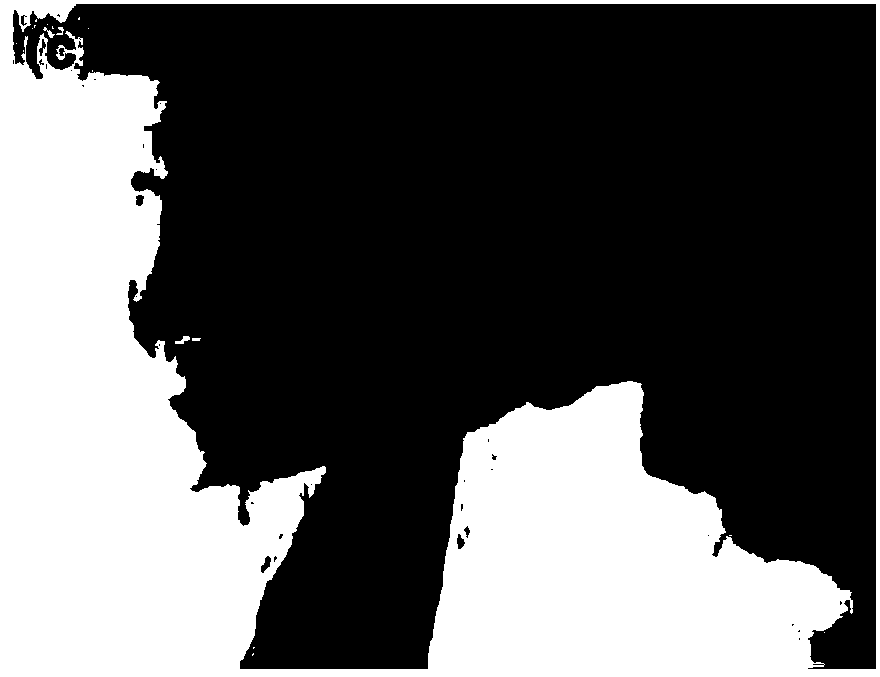

[0040] Embodiment 2 Put the nickel sheet through the standard cleaning into the chamber of the 1.5kW ASTeX plasma enhanced chemical vapor deposition system, put a quartz glass sheet (4cm * 4cm) under the nickel sheet to avoid direct contact with the molybdenum sheet, and feed 100sccm hydrogen , when the temperature increases to 650 degrees, add 1200 watts of microwave power, and at the same time pass through 1.5 sccm methane, turn off the microwave after 20 minutes of plasma treatment, let the cavity cool naturally, take out the sample and you can observe the surface of the nickel sheet with SEM Two-dimensional graphene (multilayers) grows. Then put the two-dimensional graphene-nickel sheet into the magnetron sputtering chamber, feed 10 sccm of argon gas to control the pressure at 2mTorr, add 50W RF power, sputter for 30 minutes, and then the two-dimensional graphene surface will be covered A silicon film of about 1 μm.

[0041] Afterwards, the silicon-two-dimensional graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com