Microwave plasma chemical vapor deposition device

A technology of chemical vapor deposition and microwave plasma, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of uneven distribution of gas and meet the needs of large-scale industrial production, high The effect of quality deposited film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

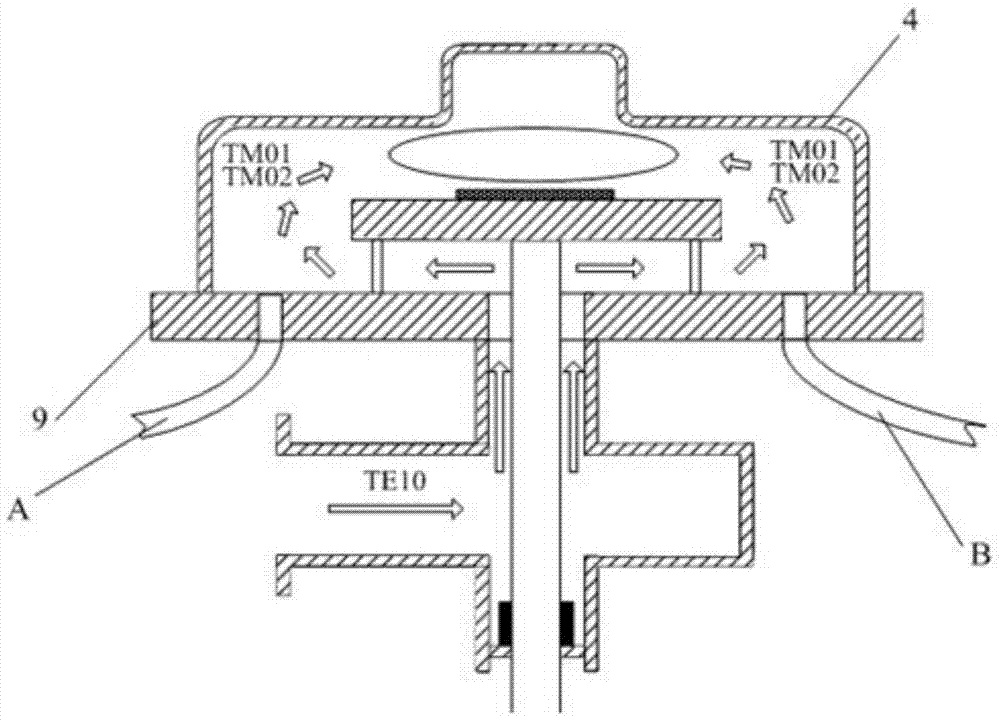

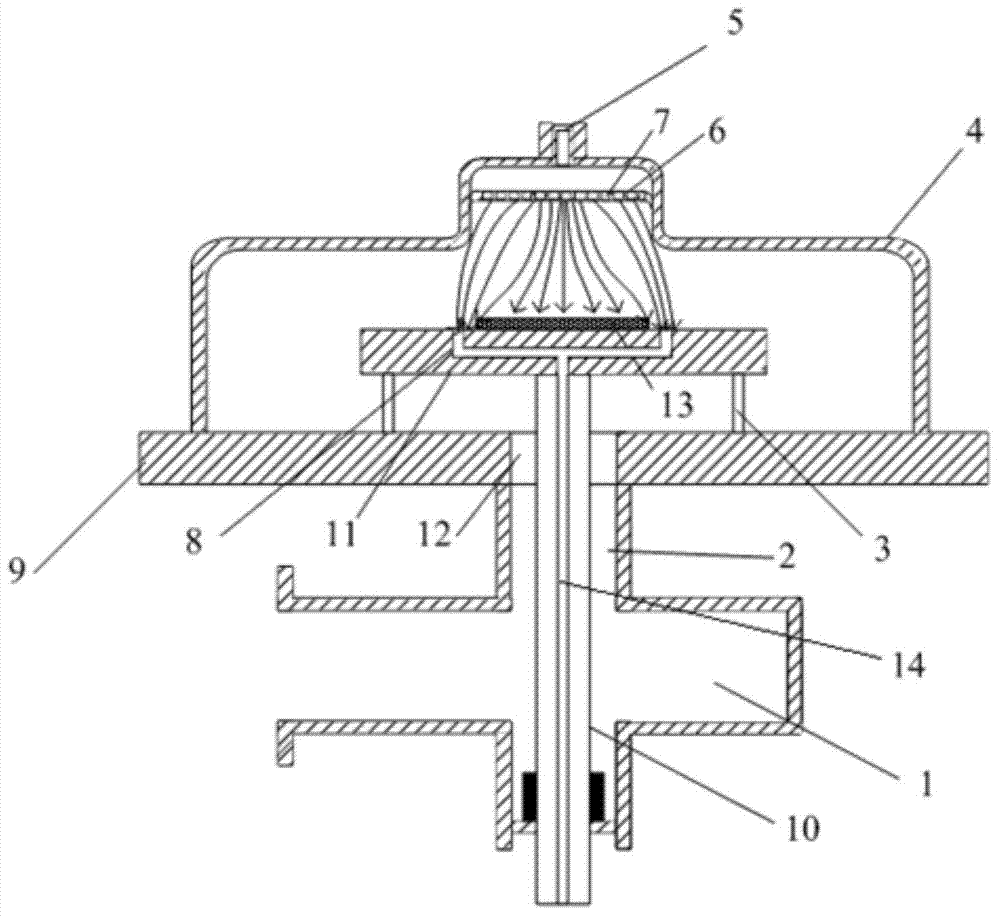

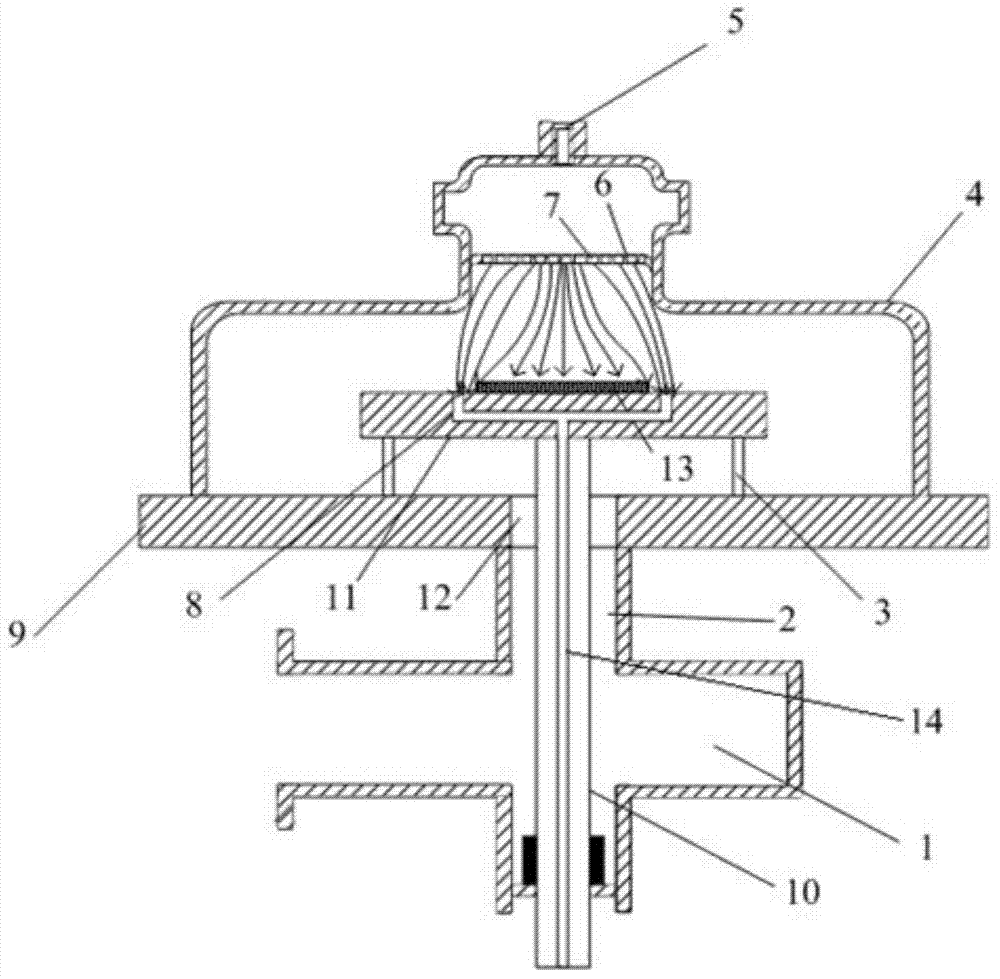

[0025] Such as figure 2 As shown, a microwave plasma chemical vapor deposition device of the present invention includes a reaction chamber composed of a reaction chamber upper cover 4 and a reaction table 9 . A connected rectangular waveguide 1 and coaxial waveguide 2 are arranged below the reaction chamber. The rectangular waveguide 1 is horizontal and used to introduce microwaves from the microwave generator and propagate TE10 single mode. The coaxial waveguide 2 is vertical and uses It is used to couple and propagate TM01 mode and TM02 mode. The reaction table 9 has a through hole 12 with the same shape and size as the inner cavity of the coaxial waveguide 2, the through hole 12 coincides with the exit of the coaxial waveguide 2, and the central axis 10 of the coaxial waveguide 2 extends into the reaction chamber through the through hole 12 .

[0026] A sample stage 11 for placing a substrate 13 is coaxially and fixedly connected above the central axis 10 . An annular q...

Embodiment 2

[0037] Such as Figure 7 As shown, the exhaust channel includes a plurality of vertical exhaust holes 8 that are evenly distributed around the circumference and are located on the sample stage 11 adjacent to the outer edge of the substrate 13. The plurality of vertical exhaust holes 8 are all connected to the The annular gas channel below it is connected, and the annular gas channel is connected with a quartz tube 15 through a horizontal exhaust channel opened radially to the outside. Station 9 is connected to external pipe fittings. combine Figure 8 As shown in , the number of horizontal exhaust passages is four and arranged in the shape of a "ten". Preferably, the diameter of the air inlet hole 7 is 1 mm, and the diameter of the vertical exhaust hole 8 is 1.5 mm.

[0038] A microwave plasma chemical vapor deposition device provided by the present invention improves the effect and efficiency of deposition and film formation, improves the quality and increases the uniformi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com