Preparation method of porous diamond film

A diamond thin film and thin film technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of high growth cost, high growth equipment requirements, and inconspicuous porous structure, so as to improve hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

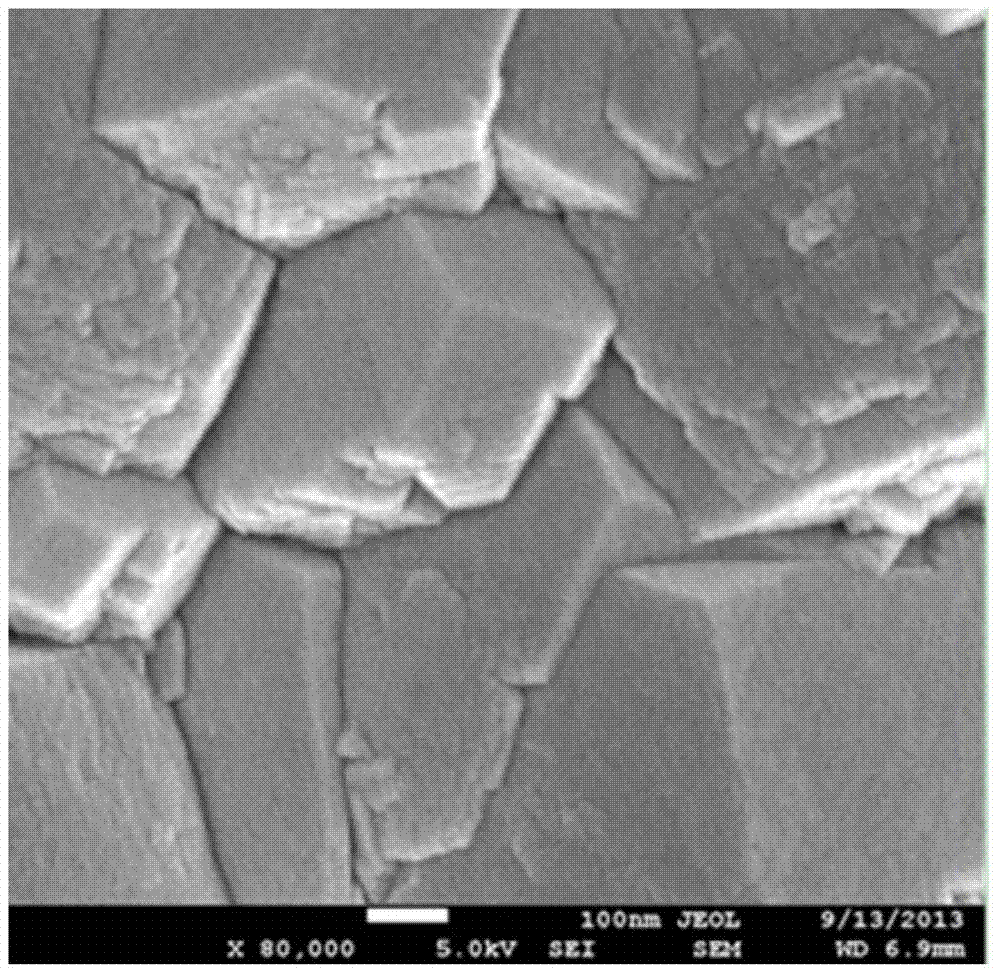

Embodiment 1

[0022] Using the microwave plasma chemical vapor deposition method, first place a silicon substrate in the middle of a quartz tube vacuum furnace. The surface of the silicon substrate is coated with a 5nm Pt film as a catalyst, and the vacuum of the vacuum tube furnace is evacuated to 10 mbar with a mechanical pump. , into H 2 and heated to 800°C, then turn on the Ar to load methyl formate to the microwave plasma generation area, the flow rate of H2 is 95 sccm, the flow rate of Ar is 5 sccm, turn on the microwave power supply and start deposition, the growth time is 5 hours, on the surface of the silicon substrate The bulk diamond film is obtained, air-cooled and then heated with air (50-70 sccm) at a heating rate of 20-30°C / min, and the bulk diamond film is calcined in an air atmosphere at 500°C for 60 minutes to obtain a porous diamond film.

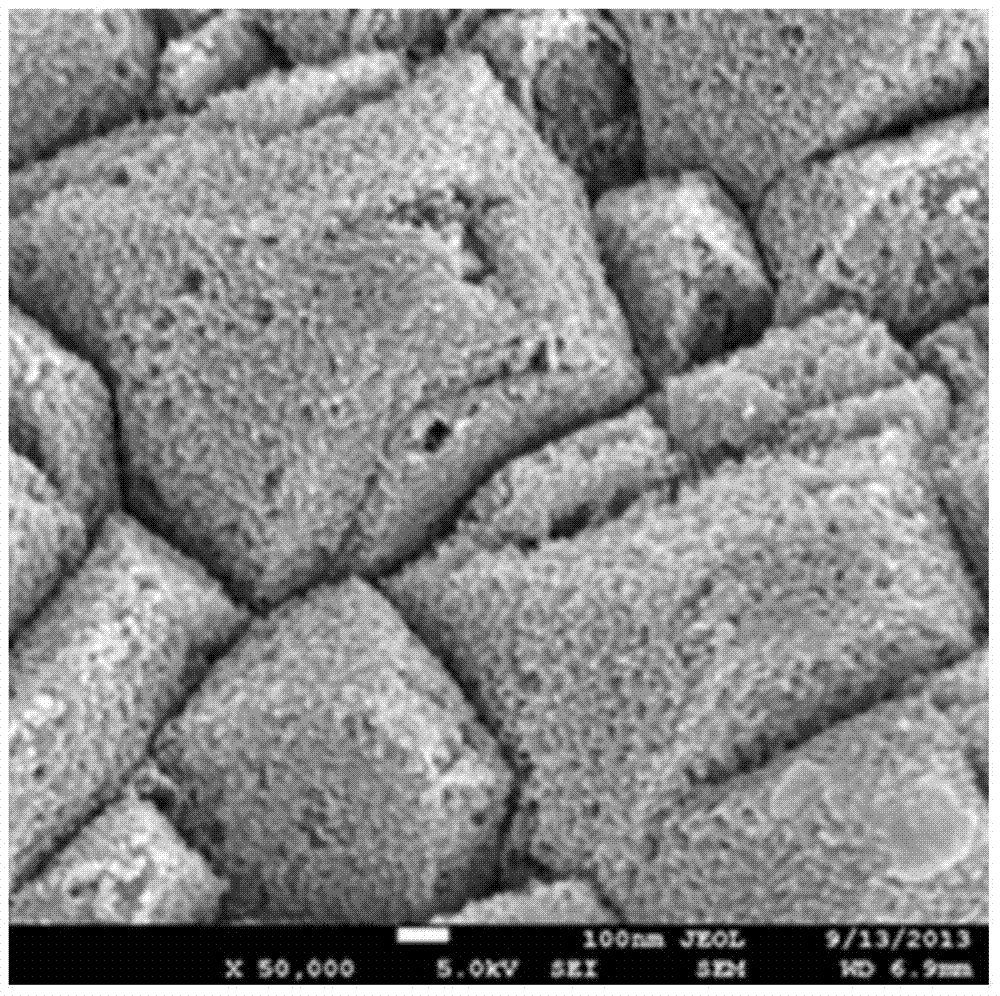

Embodiment 2

[0024] Using the microwave plasma chemical vapor deposition method, first place a silicon substrate in the middle of a quartz tube vacuum furnace. The surface of the silicon substrate is coated with a 3nm Pt film as a catalyst, and the vacuum of the vacuum tube furnace is evacuated to 30 mbar by a mechanical pump. , into H 2 And heated to 850 ℃, then turn on Ar to load methyl formate to the microwave plasma generation area, the flow rate of H2 is 99sccm, the flow rate of Ar is 1sccm, turn on the microwave power supply to start deposition, the growth time is 8 hours, on the surface of the silicon substrate The bulk diamond film is obtained, air-cooled and then heated with air (50-70 sccm) at a heating rate of 20-30°C / min, and the bulk diamond film is calcined in an air atmosphere at 600°C for 30 minutes to obtain a porous diamond film.

Embodiment 3

[0026] Using the microwave plasma chemical vapor deposition method, first place a silicon substrate in the middle of a quartz tube vacuum furnace. The surface of the silicon substrate is coated with a 3nm Pt film as a catalyst, and the vacuum of the vacuum tube furnace is evacuated to 30 mbar by a mechanical pump. , into H 2 and heated to 850°C, then open Ar to load methyl formate and B 2 h 6 To the microwave plasma generation area, the flow velocity of H2 is 99sccm, and the flow velocity of Ar is 1sccm. Turn on the microwave power supply and start to deposit. The growth time is 8 hours. A bulk diamond film is obtained on the surface of the silicon substrate, and air (50- 70 sccm) for heating at a heating rate of 20-30° C. / min, and calcining the bulk diamond film in an air atmosphere at 600° C. for 30 minutes to obtain a porous diamond film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com