Large area microwave plasma CVD device

A technology of microwave plasma and chemical vapor deposition, which is applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve the problem of deterioration of the quality of silicon film deposited by concentration, and achieve high use value and high free electron density , No electrode pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

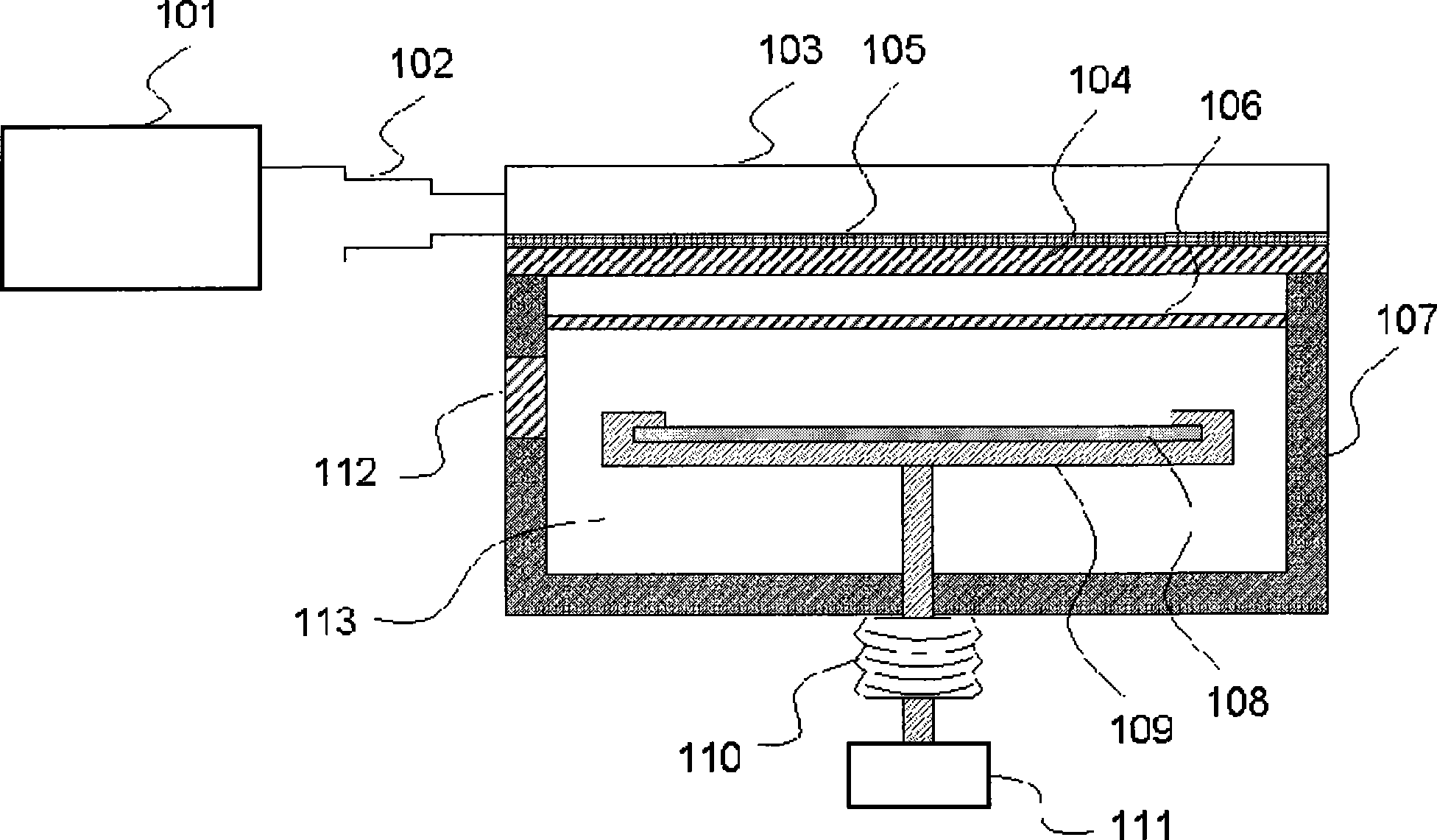

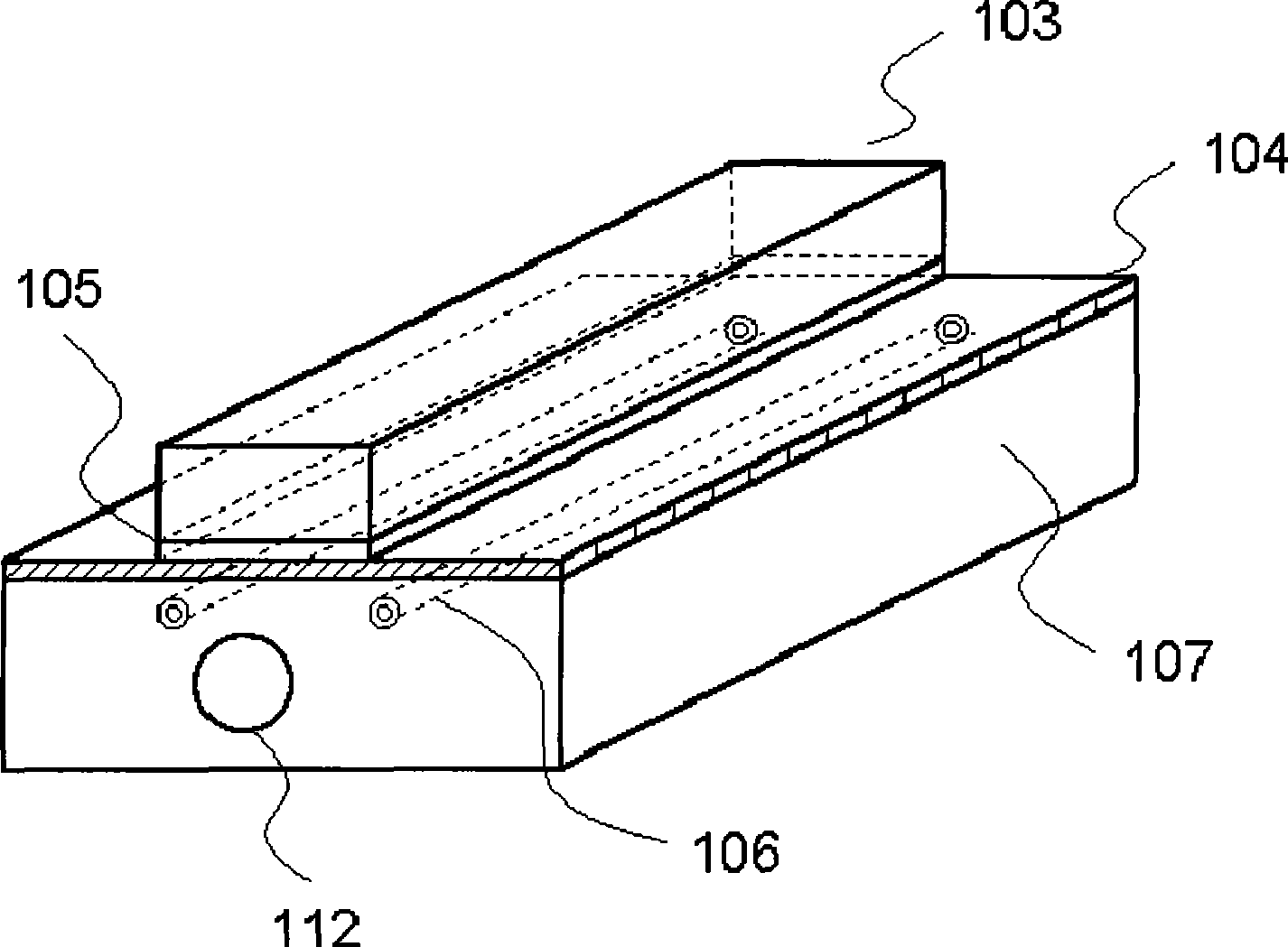

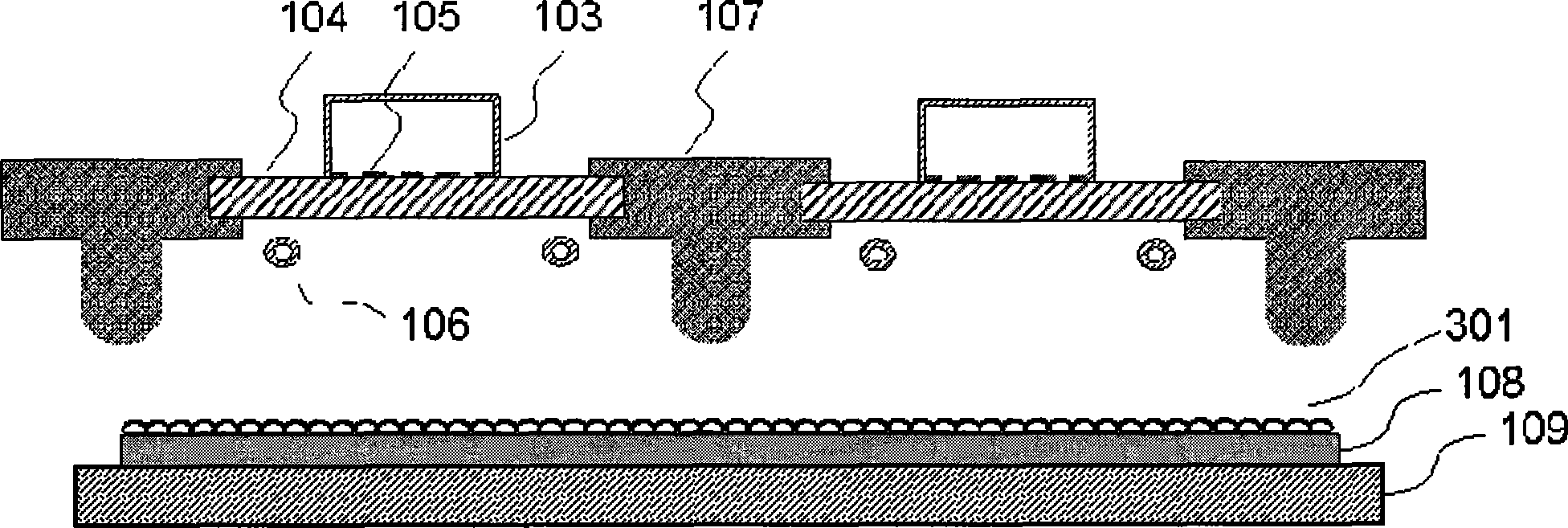

[0035] Figure 7 It is a structural schematic diagram of an embodiment of the thin film preparation device of the present invention. The microwave generated by the microwave source 101 is effectively introduced into the parallel rectangular waveguide 103 through the tapered waveguide 102. The tapered waveguide is also called a waveguide horn, and the microwave can be transmitted from the microwave generator Coupled into the waveguide with a small mismatch loss. The side-by-side rectangular waveguides 103 feed microwaves into the main chamber 113 through the replaceable microwave feeding window and the quartz glass plate 104, and in the main chamber 107, the precursor gas introduced by the gas distribution pipe 106 is excited to generate plasma, and on the substrate 108 Deposit thin films. The purpose of distributing the waveguides side by side is to excite uniform plasma in a large area to achieve the uniformity of large area film deposition.

[0036] The side-by-side rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com