Current collector for lithium ion battery positive electrode and battery with current collector

A lithium-ion battery and current collector technology, applied in the direction of electrode carrier/current collector, battery electrode, secondary battery, etc., can solve the problem that the high-speed discharge capacity and life of the battery need to be further improved, the bonding force between the active material and the current collector is insufficient, and the electrical conductivity Insufficient capacity and other problems to achieve the effect of improving high-power discharge capacity, increasing conductivity, and improving electrode life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

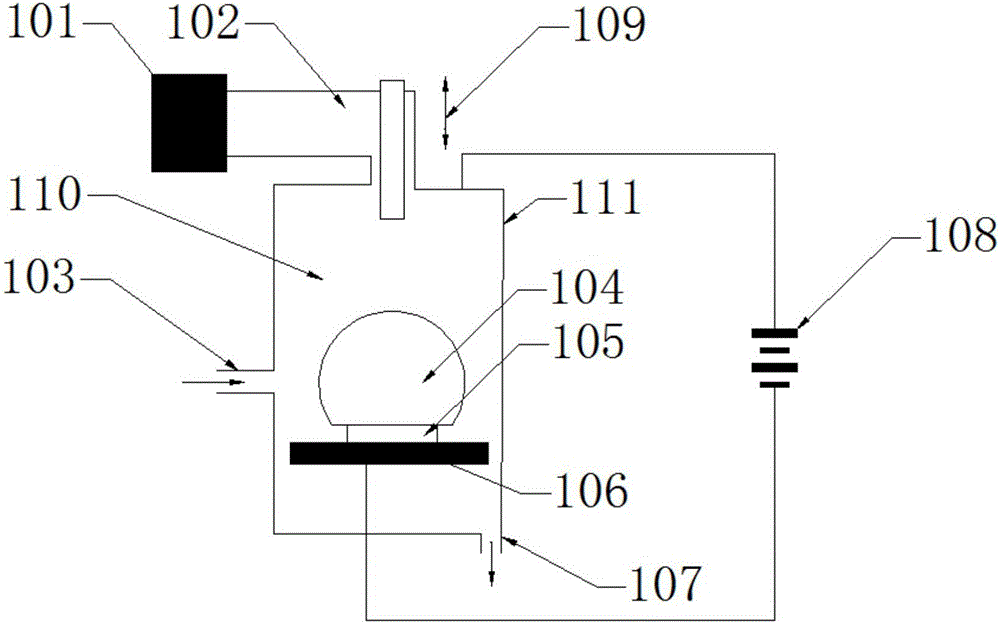

[0043] A preparation method of a current collector for a positive electrode of a lithium ion battery is a microwave plasma chemical vapor deposition method, and the process is as follows:

[0044] 1) Place the aluminum foil substrate in the vacuum container resonant cavity 110, the aluminum foil substrate 105 is connected to the cathode, and the vacuum container 111 is the anode;

[0045] 2) Vacuumize the vacuum container to 0.05-0.1Pa, fill it with argon gas to 50-70Pa, repeat 3 times, and then evacuate to 0.1-5Pa; at the same time, heat the aluminum foil substrate to 280-600°C;

[0046] 3) Under the reaction temperature and the argon pressure of 0.1-5Pa, apply a DC pulse voltage on the aluminum foil substrate 105 to form a plasma 104, treat the aluminum foil substrate for 10-30 minutes, and activate the surface of the aluminum foil substrate 105, wherein the aluminum foil substrate The value of the DC pulse voltage applied on the substrate 105 is 400-600V;

[0047] 4) After...

Embodiment 1

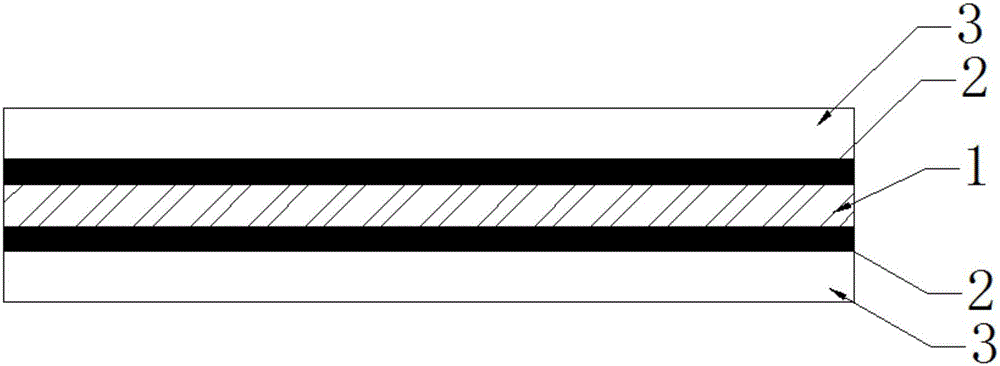

[0050] Preparation of graphene-modified cathode current collector:

[0051] (1) Place the cleaned and degreased 15-micron thick aluminum foil substrate in the vacuum resonance cavity of the microwave plasma equipment, connect the cathode, and the vacuum container is the anode;

[0052] (2) The vacuum container is evacuated to 0.1Pa, filled with argon to 50Pa, evacuated to 0.1Pa, and repeated 3 times; at the same time, the aluminum foil substrate is heated to a temperature of 350°C;

[0053] (3) Under 1.0Pa argon pressure, apply a DC pulse voltage of 600V to the aluminum foil, and use the formed plasma to activate the surface of the aluminum foil substrate for 20 minutes;

[0054] (4) Introduce 2.4GHz microwaves and hydrocarbon gas (mixed gas of ethanol: argon = 1:0.5) into the resonant cavity of the vacuum container, keep the reaction temperature of the resonant cavity at 380°C, and conduct the deposition process for 50 minutes at a pressure of 2Pa, then stop Introducing micr...

Embodiment 2

[0061] Preparation of graphene-modified cathode current collector:

[0062] (1) Place the cleaned and degreased 20-micron thick aluminum foil substrate in the vacuum resonance cavity of the microwave plasma equipment, connect the cathode, and the vacuum container is the anode;

[0063] (2) The vacuum container is evacuated to 0.1Pa, filled with argon to 50Pa, evacuated to 0.1Pa, and repeated 3 times; at the same time, the aluminum foil substrate is heated to a temperature of 550°C;

[0064] (3) Under 5.0Pa argon pressure, apply a DC pulse voltage of 500V to the aluminum foil, and use the formed plasma to activate the surface of the aluminum foil substrate for 20 minutes;

[0065] (4) Introduce 2.4GHz microwaves and hydrocarbon gas (ethanol: argon = 1:1 mixed gas) into the resonant cavity of the vacuum container, keep the resonant cavity reaction temperature at 500°C, and deposit for 30 minutes at a pressure of 5 Pa, then stop Introduce microwave and hydrocarbon gas, reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com