Method for manufacturing porous diamond or porous cubic silicon carbide self-supporting film

A cubic silicon carbide, self-supporting film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of increasing production cost, increasing the steps of removing metal electrodes, etc., to achieve low production cost, The effect of good stability and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the preparation method of porous diamond and porous cubic silicon carbide established according to the present invention, in step 2, the base material pretreated in step 1 is put into chemical vapor deposition equipment, and the vapor phase deposition equipment includes: microwave plasma chemical vapor phase deposition and hot wire chemical vapor deposition. Reactive gases are hydrocarbons, organosilanes and hydrogen.

[0040] In a preferred embodiment of the method according to the invention, the chemical vapor deposition is carried out at a temperature of 500-1000°C, preferably 700-900°C, still more preferably 750-850°C. When the temperature is higher than 1000°C or lower than 500°C, the growth of diamond is inhibited, so that the diamond / cubic silicon carbide composite film cannot be obtained.

[0041] In the preparation method of porous diamond and porous cubic silicon carbide established according to the present invention, in step 2, the reactive gas used for c...

Embodiment

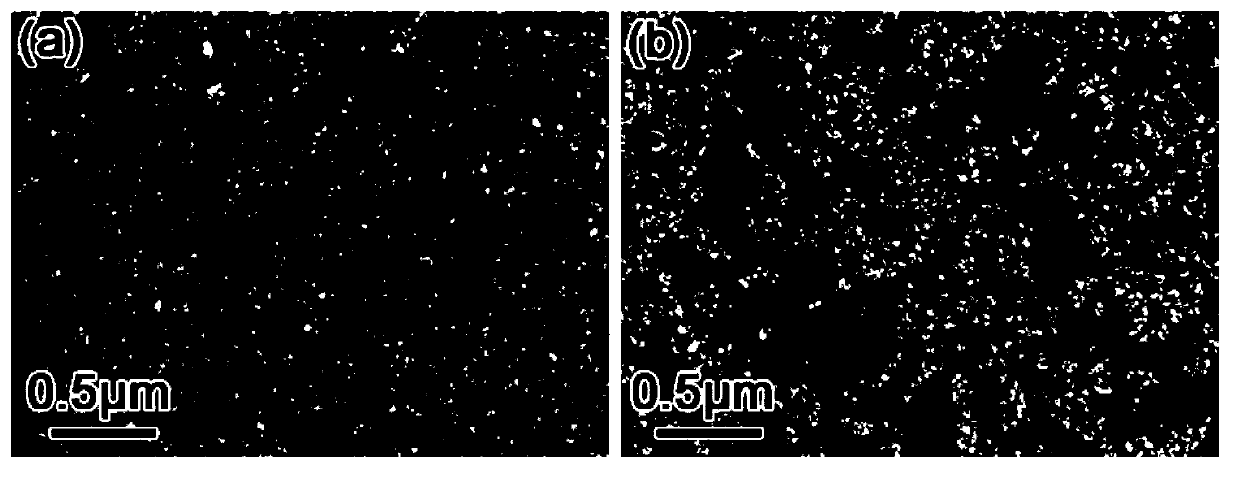

[0049] A high diamond nucleation rate was obtained by immersing a 2-inch silicon wafer in a diamond-containing solution for 30 minutes. Clean the silicon wafer and put it into the microwave plasma vapor deposition equipment. Vacuumize so that the air pressure in the chamber is less than 1×10 -2 Torr, feed hydrogen to 25 Torr, while heating the substrate to 700°C. Then the microwave plasma was excited and the microwave power was fixed to 700W, and methane and tetramethylsilane were passed through to deposit the composite film. figure 2 (a) and (b) show two composite films with different diamond / cubic SiC ratios. figure 2 (a) The composite film shown has a high diamond content, and the concentration ratio of organosilane and methane used to deposit this sample is 20‰; figure 2 (b) shows a composite film with a high cubic SiC content. The concentration ratio of organosilane and methane used to deposit this sample is 60‰.

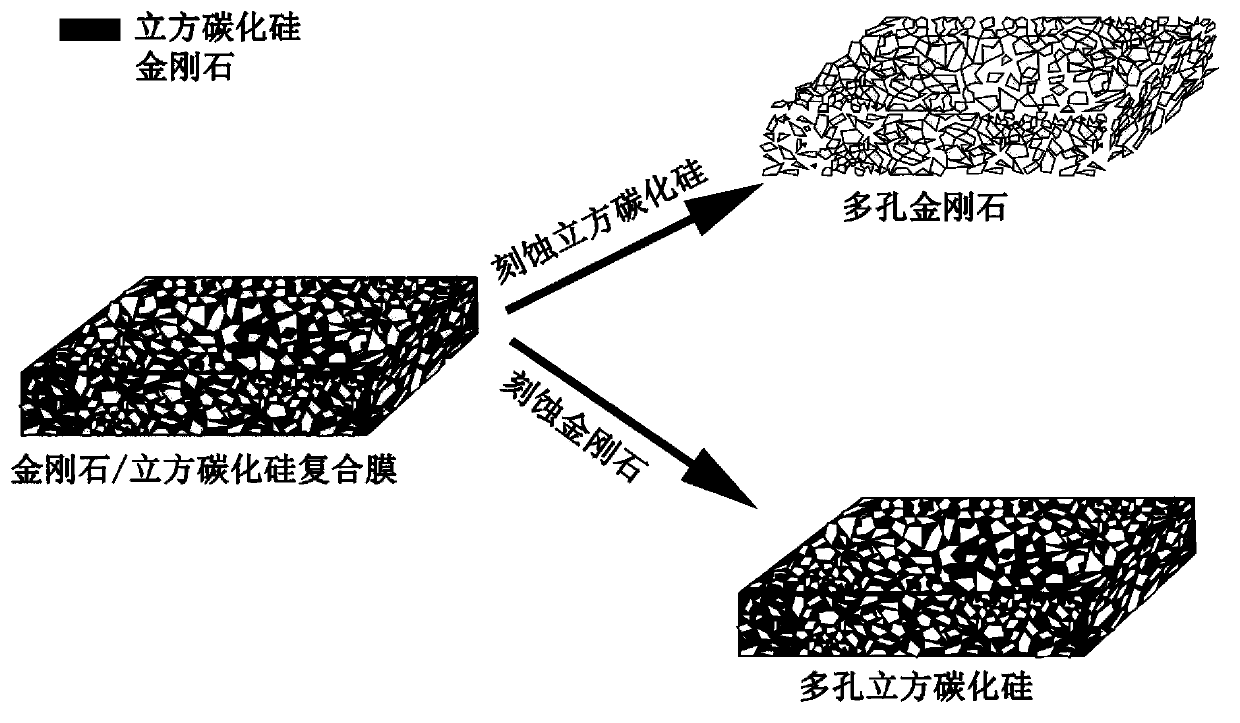

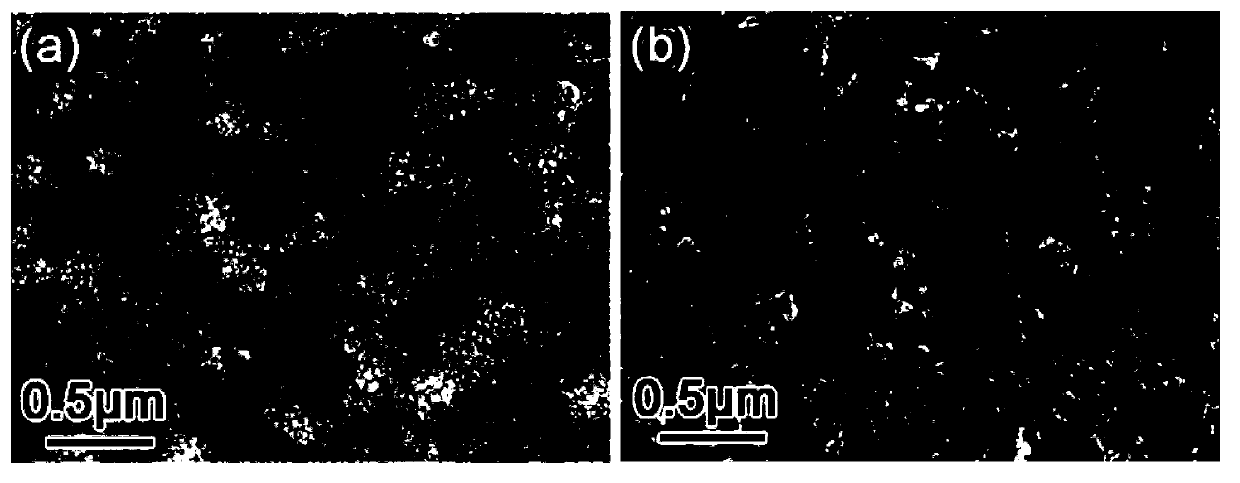

[0050] The obtained composite film was corroded in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com