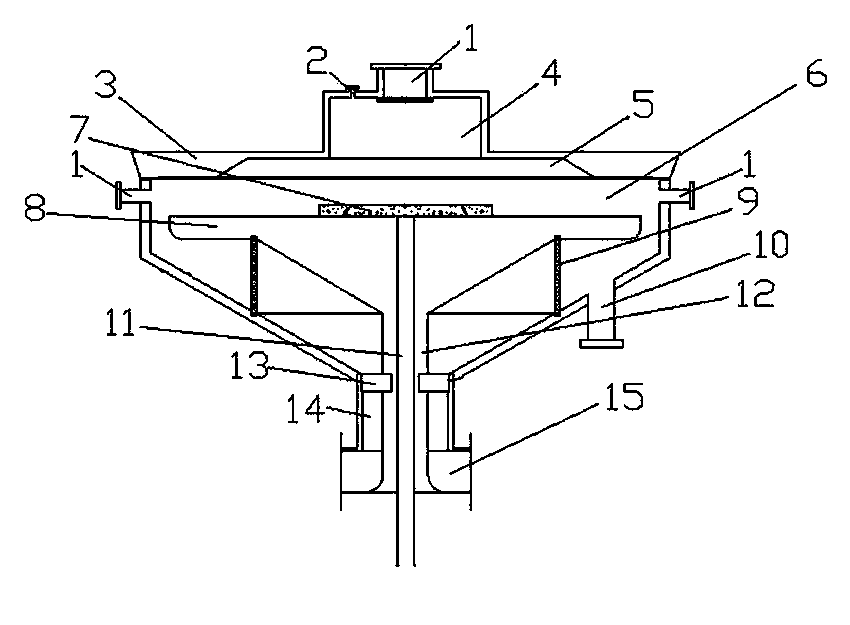

Large-area microwave plasma chemical vapor deposition system

A microwave plasma and chemical vapor deposition technology, applied in the field of plasma chemical vapor deposition system, can solve the problems of high power operation difficulty, deposition difficulty, quartz window damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will now be described in conjunction with the accompanying drawings, and the present invention is not limited to the following embodiments.

[0010] The water-cooled vacuum chamber 6 is made of stainless steel and other preferred metals that are not easily deformed by heat. The vacuum chamber body 6 has a water-cooled vacuum chamber loam cake 3, which is made of stainless steel and other preferred metals that are not susceptible to high temperature deformation. The top of the vacuum chamber loam cake 3 is provided with an air inlet 2 for air intake and for observation work state observation window 1, and four observation windows 1 are also provided around the vacuum chamber 6 to observe the working state. The inside of the vacuum chamber upper cover 3 is respectively provided with two recesses 4 and 5 of different sizes, and the recess 4 The role is to enable the generation of TM on the substrate 01 The equipotential surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com