Single point diamond lathe and method for machining special-shape workpiece

A single-point diamond and special-shaped workpiece technology, which is applied in the processing field of single-point diamond lathes and special-shaped workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

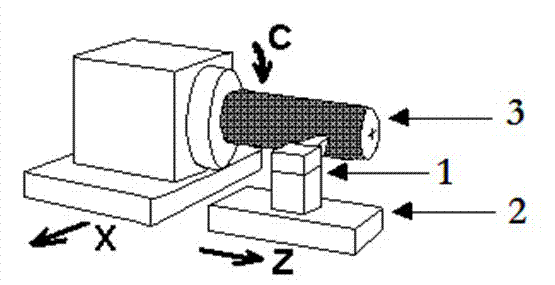

[0025] Please see first figure 1 , figure 1 It is a schematic diagram of the structure of the single-point diamond numerical control lathe of the present invention. As shown in the figure, a single-point diamond lathe includes the workpiece axial displacement guide rail axis Z axis, lateral displacement guide rail axis X axis and single crystal diamond tool 1 of the conventional numerical control lathe. , add a spindle rotation indexing axis C axis on the radial displacement guide rail shaft, install an adjustable three-dimensional tool rest 2 on the workpiece axial displacement guide rail shaft, and the single crystal diamond tool It is fixed on the three-dimensional tool rest, the workpiece 3 to be processed is fixed on the spindle indexing axis, the Z-direction displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com