Base material for growing single crystal diamond and method for producing single crystal diamond substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

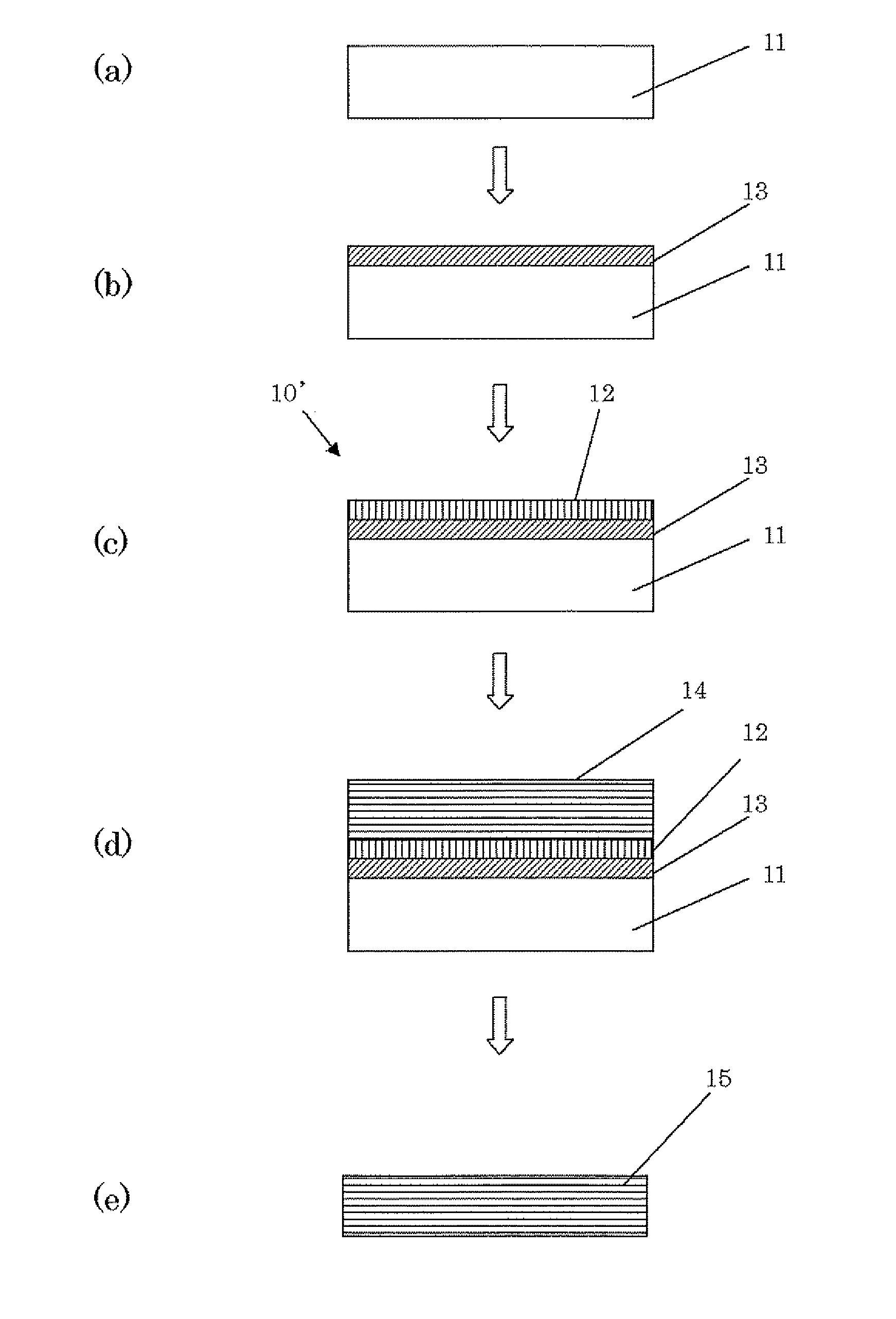

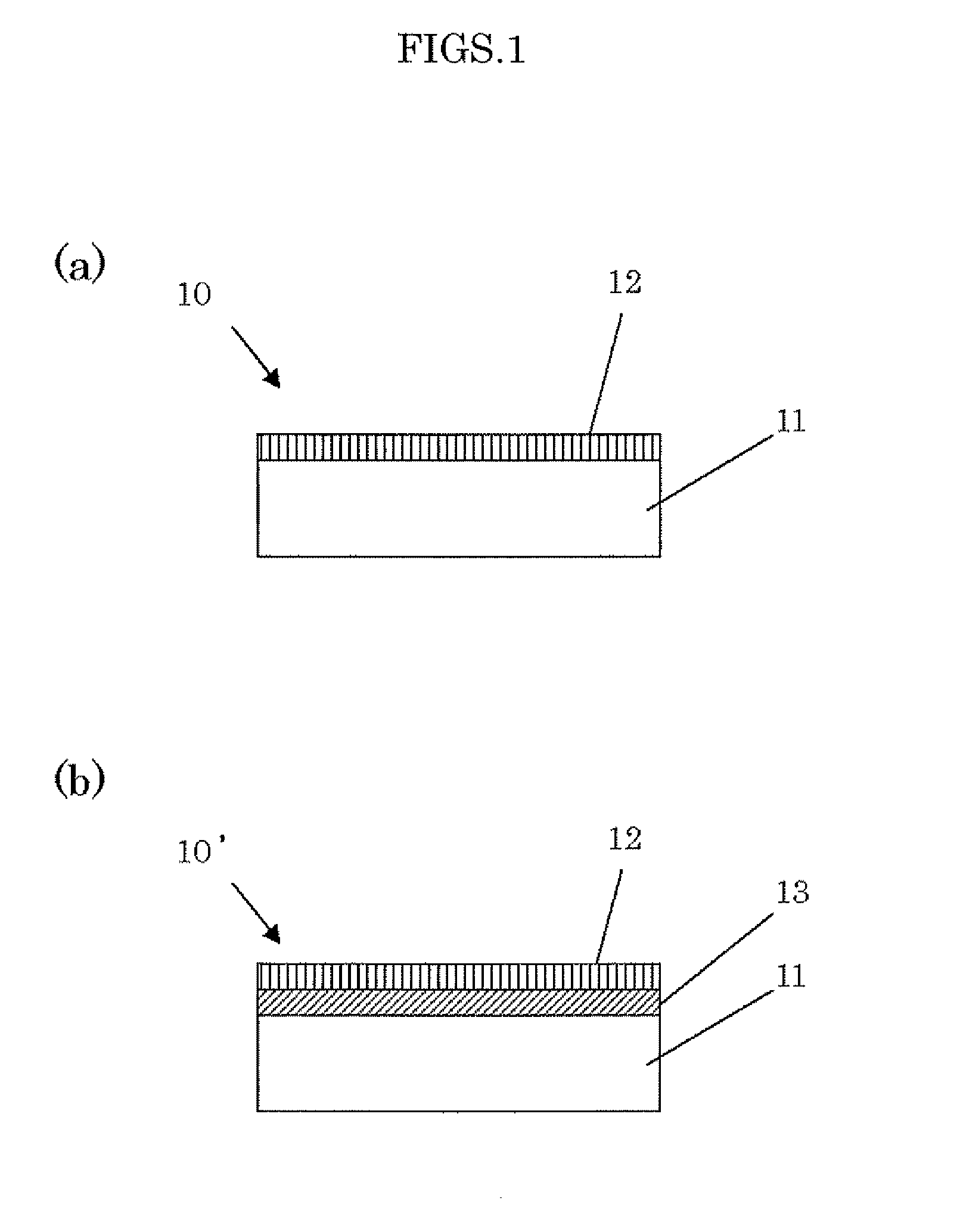

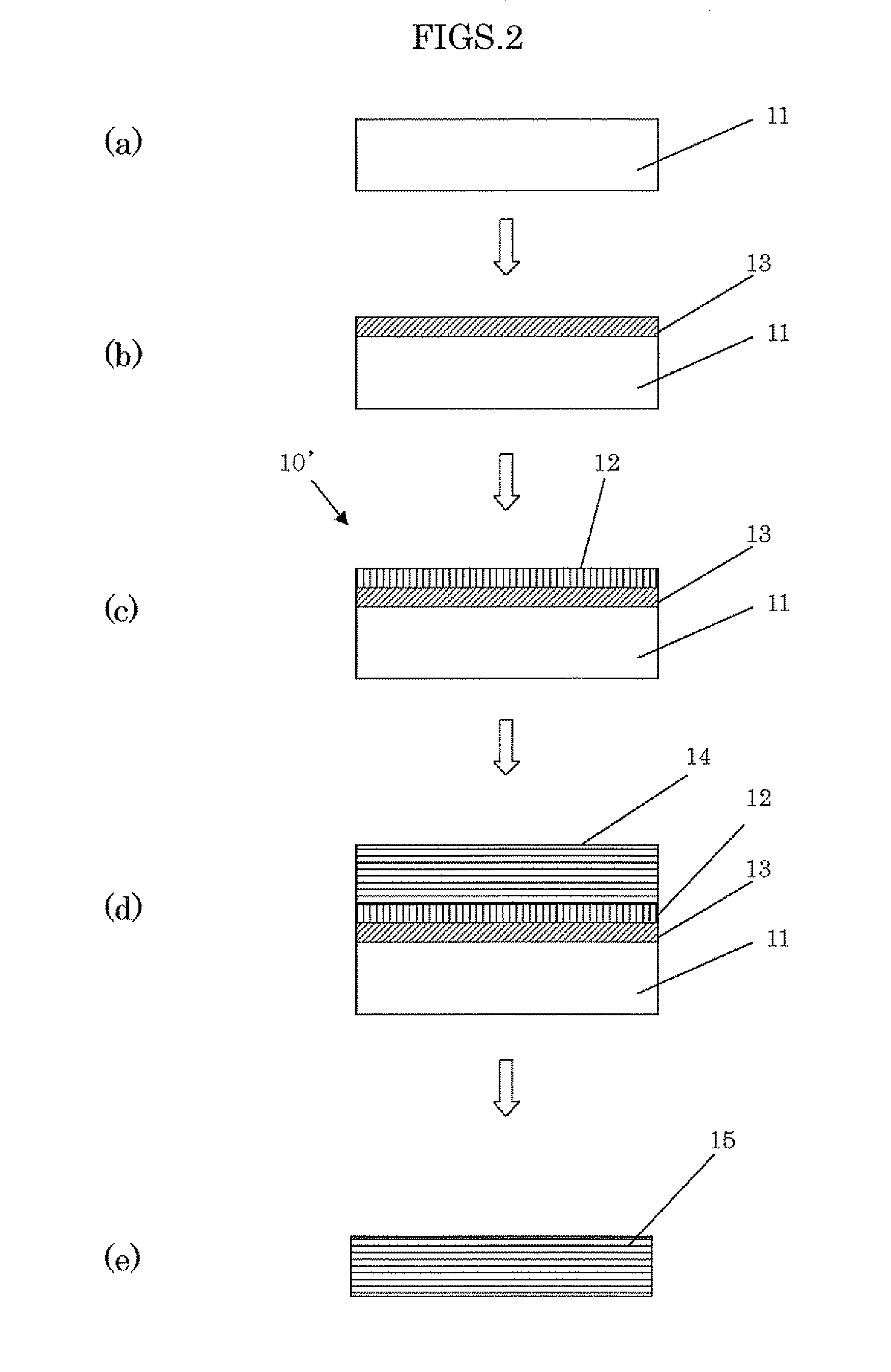

As the seed base material, there was prepared a double-side-polished single crystal β-SiC substrate having a diameter of 20.0 mm, a thickness of 0.25 mm and an orientation (100). The MgO film having a thickness of 0.1 μm was epitaxially grown, by the electron beam evaporation method, on the side of the seed base material where the single crystal diamond was to be grown in a vacuum under the conditions of a substrate temperature of 800° C.

Next, the iridium (Ir) film was heteroepitaxially grown on the single crystal MgO film. The film-forming was completed by performing the sputtering with the R. F. magnetron sputtering method in which an target was Ir under the conditions of an Ar gas of 8 Pa (6×10−2 Torr) and a substrate temperature of 700° C., until a thickness of the single crystal Ir film became 1.5 μm.

For the sake of electrical continuity in the bias treatment and the direct-current plasma CVD, the Ir film having a thickness of 1.5 μm was also grown on a back surface under the s...

example 2

Except for heteroepitaxially growing the It film directly without forming the MgO film on the β-SiC substrate that was the seed base material, the single crystal diamond was heteroepitaxially grown as with Example 1.

A product taken out from the bell jar was a laminated structure of the diamond / Ir / SiC without the break. In this case, since the product was composed of only high chemical resistance materials and was not able to separate by the wet etching with hot mixed acid, it was cut with laser at the vicinity of the interfaces between the diamond and the Ir to get self-standing structure of the single crystal diamond (the single crystal diamond substrate). The surface was also subjected to a final polishing so that it was finished so as to have surface roughness of a usable level for device application.

It was confirmed that the obtained single crystal diamond substrate had sufficient crystallinity as a result of evaluation by raman spectroscopy, XRD rocking curve, X-sectional TEM a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com