Preparation method of high-performance diamond reinforced Al-matrix electronic packaging composite material

A technology for electronic packaging and composite materials, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc. It can solve the problems of uniformity of material structure, difficulty in controlling the graphitization of dense diamond, and difficulty in exerting the excellent properties of diamond, and the interface between the two phases. To achieve the effect of strong repeatability, improved density, and improved material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

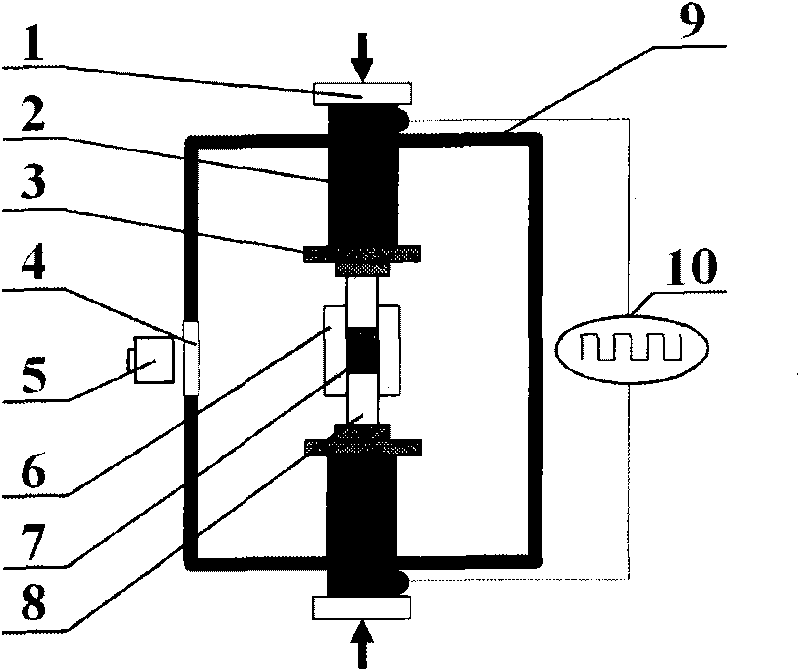

Method used

Image

Examples

Embodiment 1

[0023] The particle size of single crystal diamond is 198 μm, the particle size of pure Al powder is less than 74 μm, and the volume ratio of diamond and pure Al powder is 60:40.

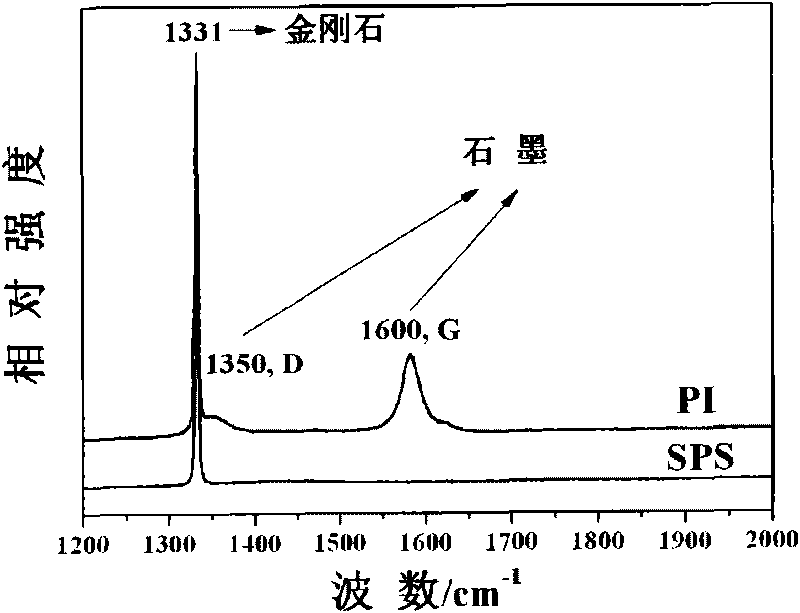

[0024] According to the designed raw material ratio, dry-mix single crystal diamond particles and pure Al powder in a planetary ball mill for 30 minutes at a speed of 350 r / min. After mixing evenly, spark plasma sintering (SPS) is carried out. The sintering process is as follows: the sintering temperature is 640 °C, Raise the temperature at a heating rate of 80°C / min. When the temperature reaches 400°C, apply a sintering pressure of 40MPa. After reaching a sintering temperature of 640°C, heat and hold pressure for 10 minutes. The sintering is completed. After cooling to 150°C with the furnace, the mold is removed and the material is prepared. Finish. The density of the prepared Al-diamond composite material is >91%, while the thermal conductivity reaches 227W / m·K, and the density is 2.91g / cm 3 .

Embodiment 2

[0026] The particle size of single crystal diamond is 25 μm, the pure Al powder is less than 74 μm, and the volume ratio of diamond to pure Al powder is 60:40.

[0027] According to the designed raw material ratio, dry-mix single crystal diamond particles and pure Al powder in a planetary ball mill for 30 minutes at a speed of 350 r / min. After mixing evenly, spark plasma sintering (SPS) is carried out. The sintering process is as follows: the sintering temperature is 640 °C, Raise the temperature at a heating rate of 50°C / min. When the temperature reaches 400°C, apply a sintering pressure of 40MPa. After reaching a sintering temperature of 640°C, heat and hold pressure for 10 minutes. The sintering is completed. After cooling to 150°C with the furnace, the mold is removed and the material is prepared. Finish. The density of the prepared Al-diamond composite material is >96%, while the thermal conductivity reaches 287W / m K, the thermal expansion coefficient is 7.36ppm / K, and th...

Embodiment 3

[0029] The single crystal diamond particle size is 25 μm, and the Al and Si elemental powders with a particle size of <74 μm are mixed into an elemental element mixed powder with a Si content of 1 wt.%, and the volume ratio of diamond to mixed powder is 25:75.

[0030] According to the designed raw material ratio, dry-mix single crystal diamond particles and Al and Si elemental element mixed powder in a planetary ball mill for 60 minutes at a speed of 350r / min. After mixing evenly, conduct spark plasma sintering (SPS). The sintering process is: sintering temperature 600°C, heat up at a heating rate of 50°C / min, apply a sintering pressure of 40MPa when the temperature reaches 400°C, keep the heat and pressure for 10 minutes after reaching the sintering temperature of 600°C, and complete the sintering, cool to 150°C with the furnace and take it out , the material preparation is completed. The density of the prepared Al-1wt.% Si-diamond composite material reaches 98.5%, while the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com