Log spliced board structure

A technology for assembling panels and logs, applied in the field of assembled wood panel structures, can solve the problems affecting the service life and application aesthetics of the assembled wood panel products, affecting the service life of the assembled wood panels, affecting the aesthetics of the assembled wood panels, etc., so as to improve the appearance and aesthetics. , to prevent corrosion and moth-eaten, to prevent the effect of expansion deformation or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

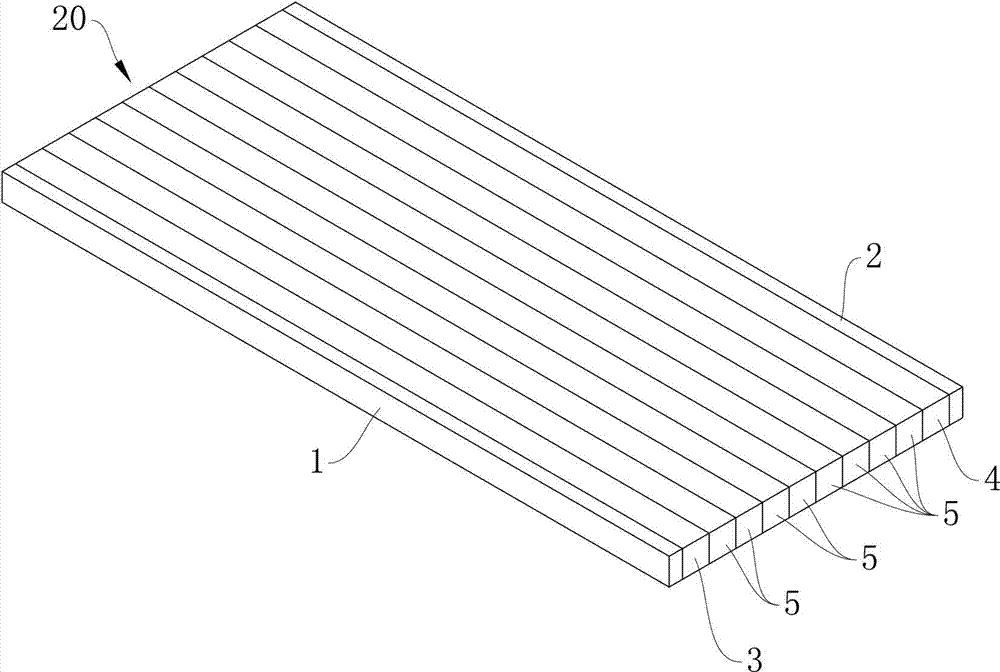

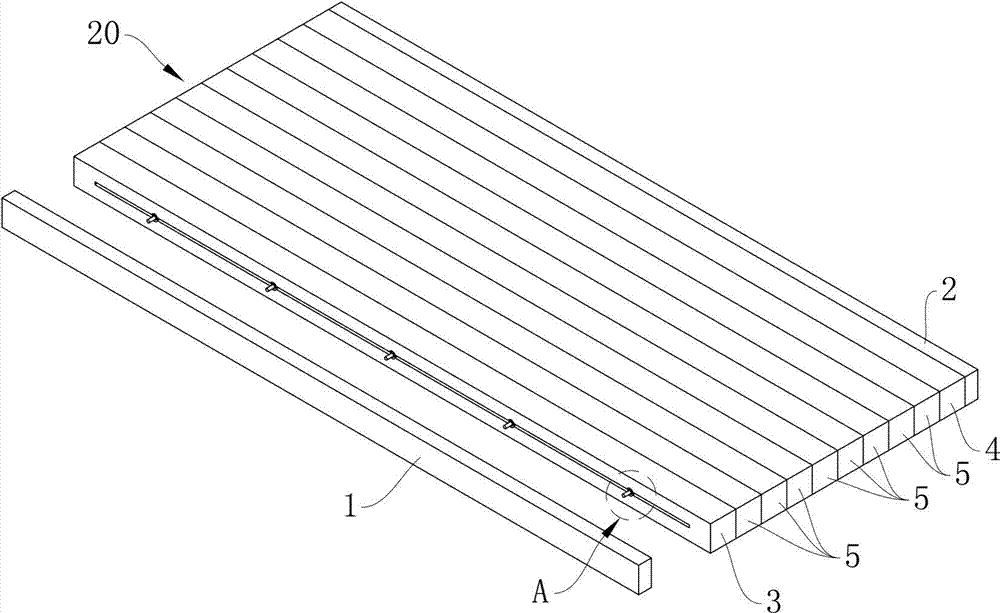

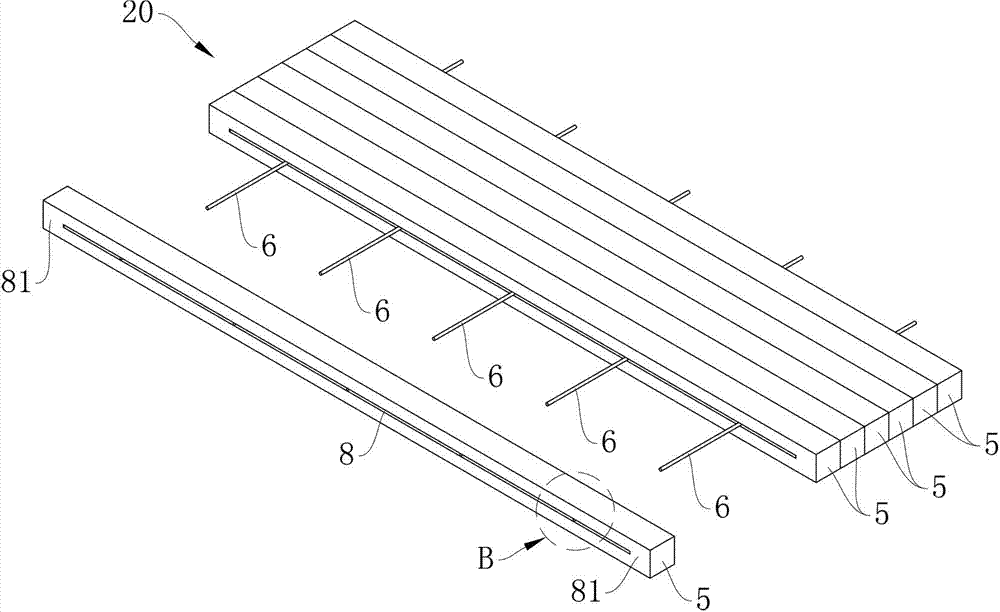

[0018] Such as Figure 1 to Figure 11 As shown, a kind of log jigsaw structure according to the present invention comprises a leftmost outer wooden square part 1, a right outermost wooden square part 2, a left second outer wooden square part 3, a right second outer wooden square part 4, Several intermediate wooden square parts 5, several serially connected screw rods 6 and several nuts 7, wherein

[0019] Such as Figure 7 and Figure 11 As shown, expansion slots 8 and a plurality of screw holes 9 are respectively provided on the inner surfaces of the leftmost outer wooden square part 1 and the right outermost wooden square part 2, and the leftmost outer wooden square part 1 and the rightmost outer wooden square part The outer surface of the outer wooden square part 2 is made into a planar structure. It should be noted here that the structure of the leftmost outer wooden square part 1 is exactly the same as that of the right outermost wooden square part 2, therefore, Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com