Splicing device of building curtain wall aluminum plate and splicing method thereof

A technology of splicing device and curtain wall, applied in construction, building components, building structure, etc., can solve the problems of low work efficiency, troublesome splicing steps of curtain wall aluminum plate body, uneven surface, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

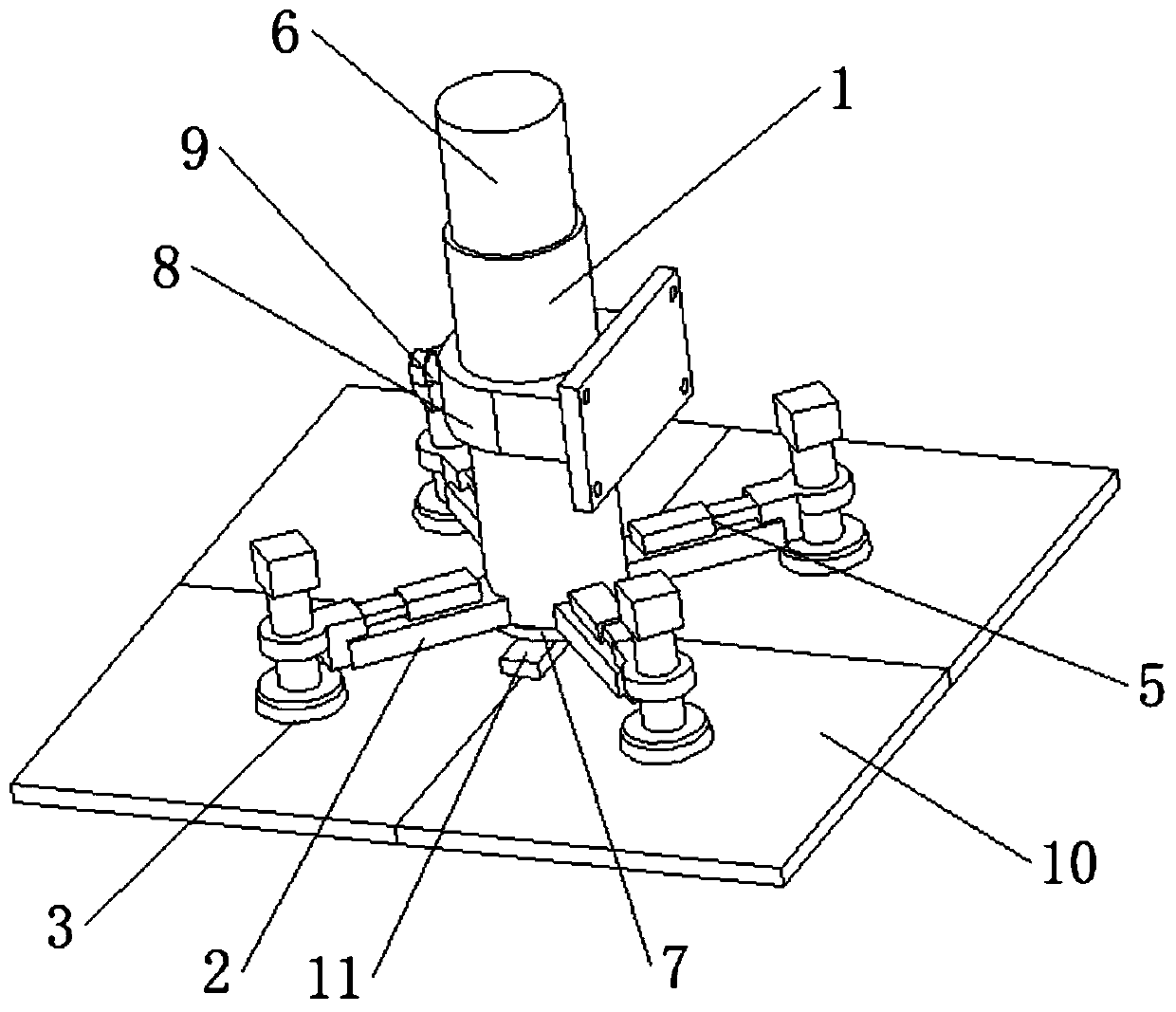

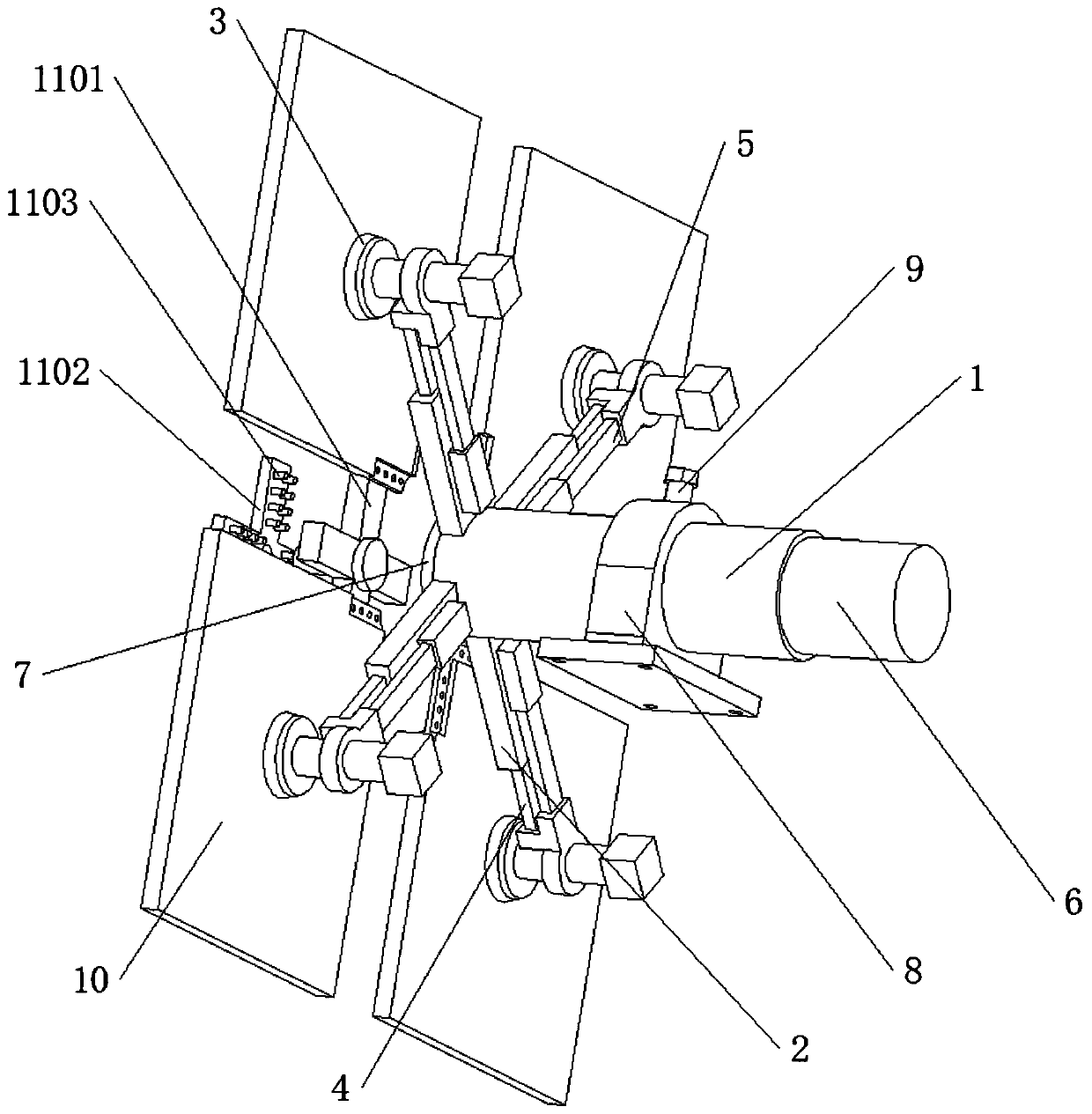

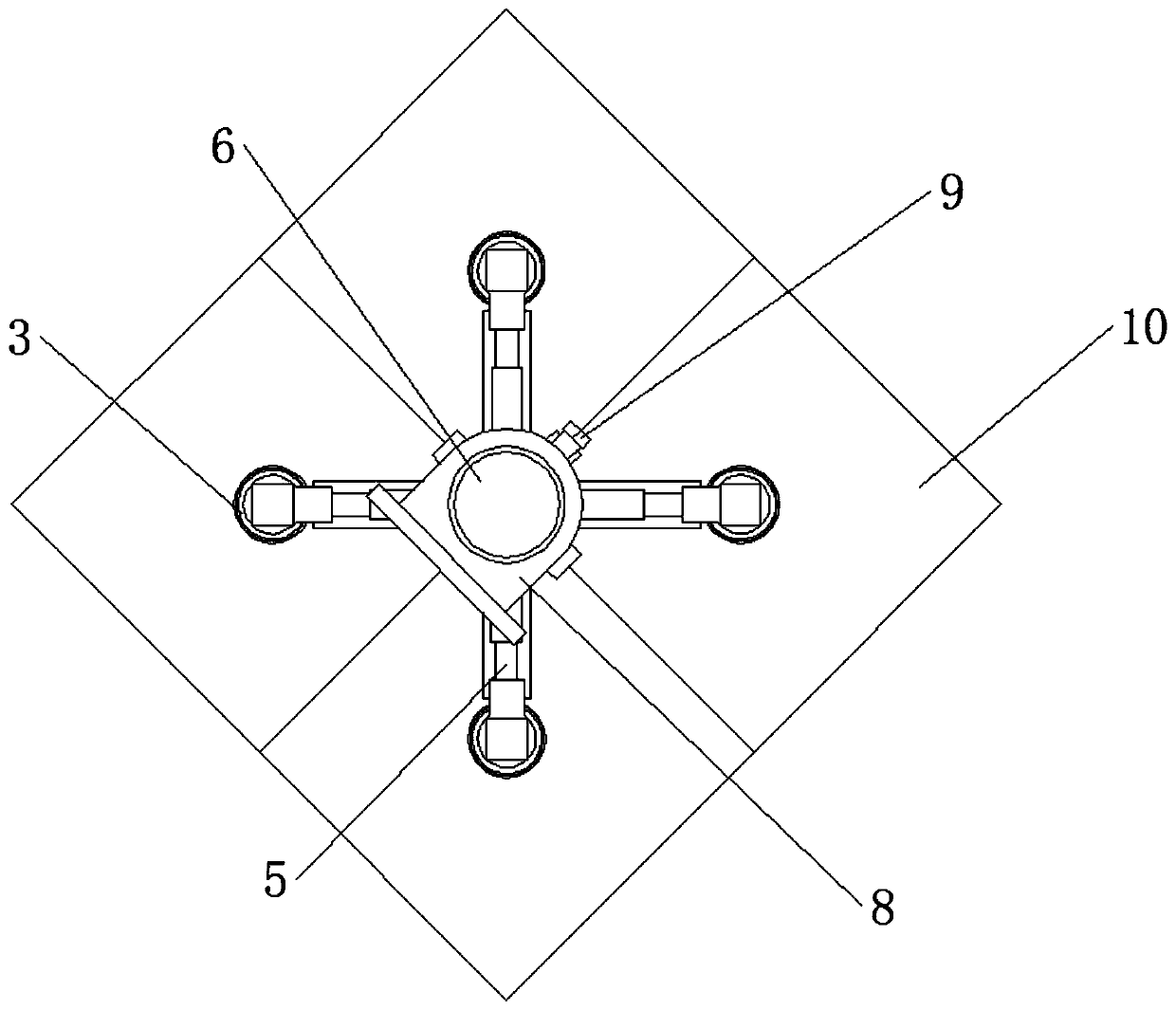

[0039] see figure 1 , figure 2 and image 3, a splicing device for building curtain wall aluminum panels, including a shaft tube 1, two pairs of extension plates 2 are fixed on the lower end of the shaft tube 1, a chute is dug at the end of the extension plate 2 away from the shaft tube 1, and a positioning rod is slidably connected in the chute 4. The positioning rod 4 is fixedly connected with a vacuum suction cup 3, the specifications of the four vacuum suction cups 3 are exactly the same, and the four vacuum suction cups 3 are connected with the same vacuum device to ensure that four identical vacuum suction cups 3 work at the same time, thereby ensuring four The curtain wall aluminum plate body 10 is located on the same horizontal plane when being sucked by four vacuum suction cups 3 respectively, the curtain wall aluminum plate body 10 is connected to the vacuum suction cup 3, the cylinder 5 is connected between the vacuum suction cup 3 and the extension plate 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com