Numerical control wood house tenon machine

A tenon machine and wooden house technology, which is applied in the direction of wood processing equipment, dovetail tenon processing, manufacturing tools, etc., can solve the problems of low precision and easy occurrence of empty positions, and achieve the effect of improving processing accuracy and tight splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

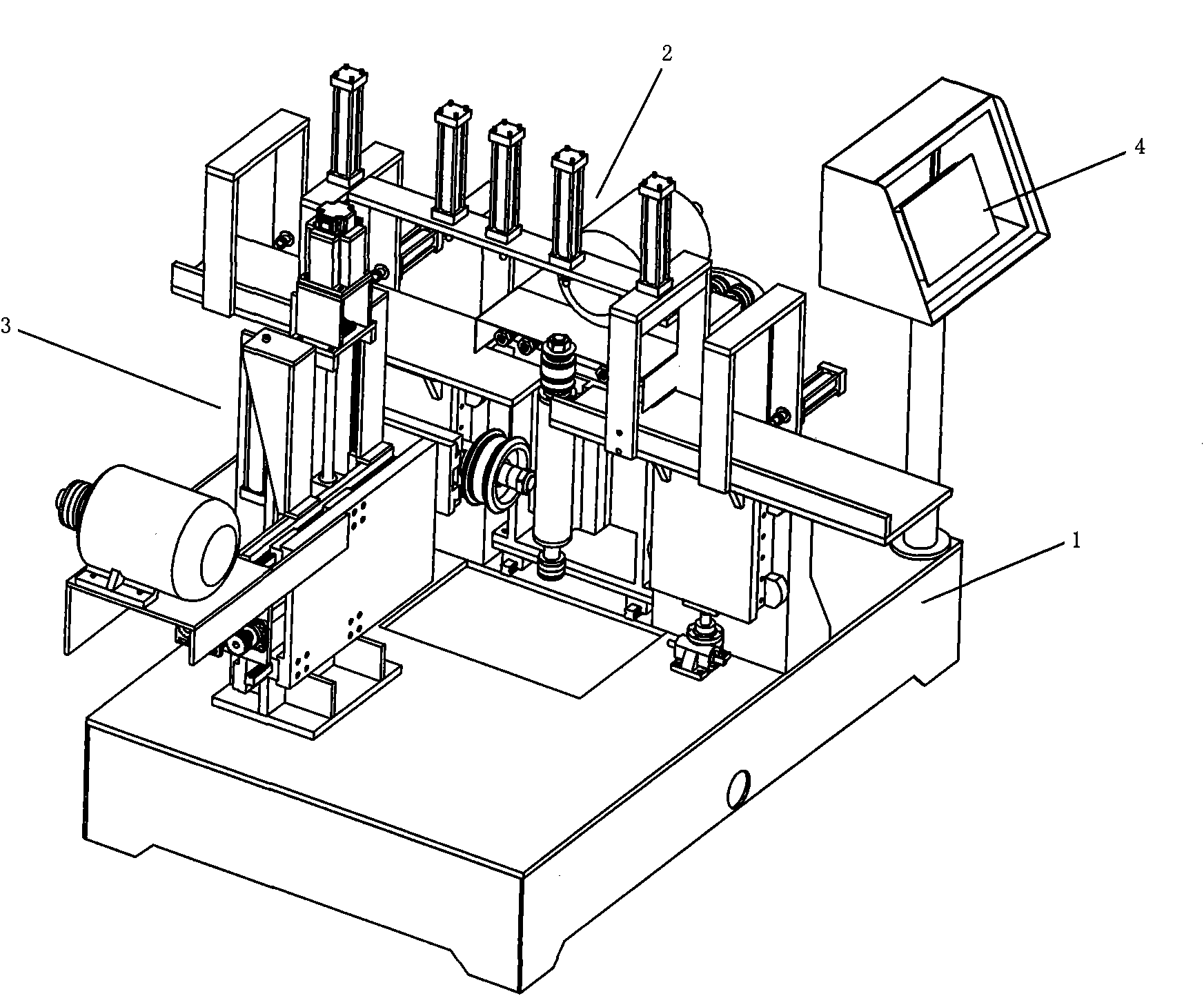

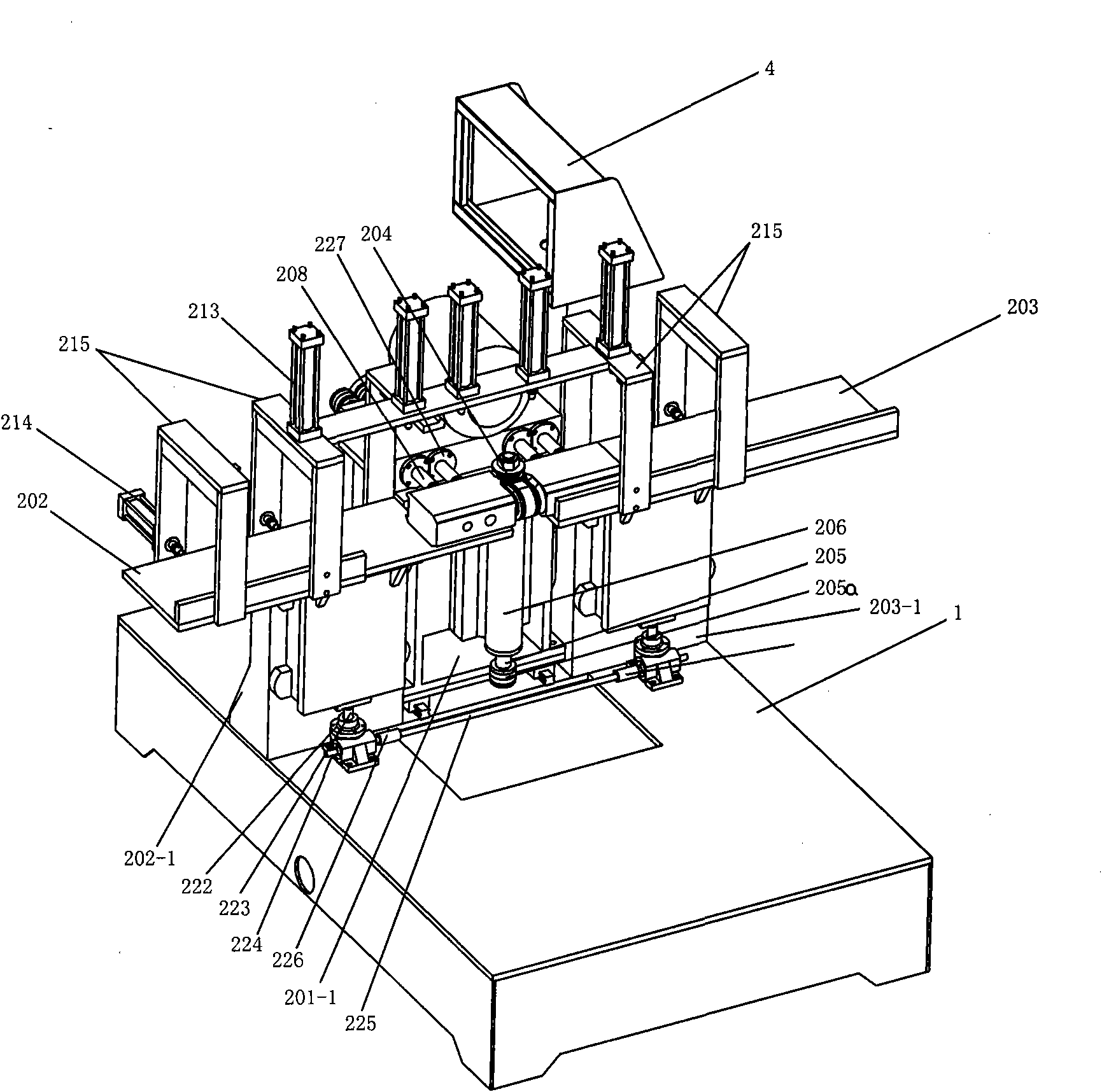

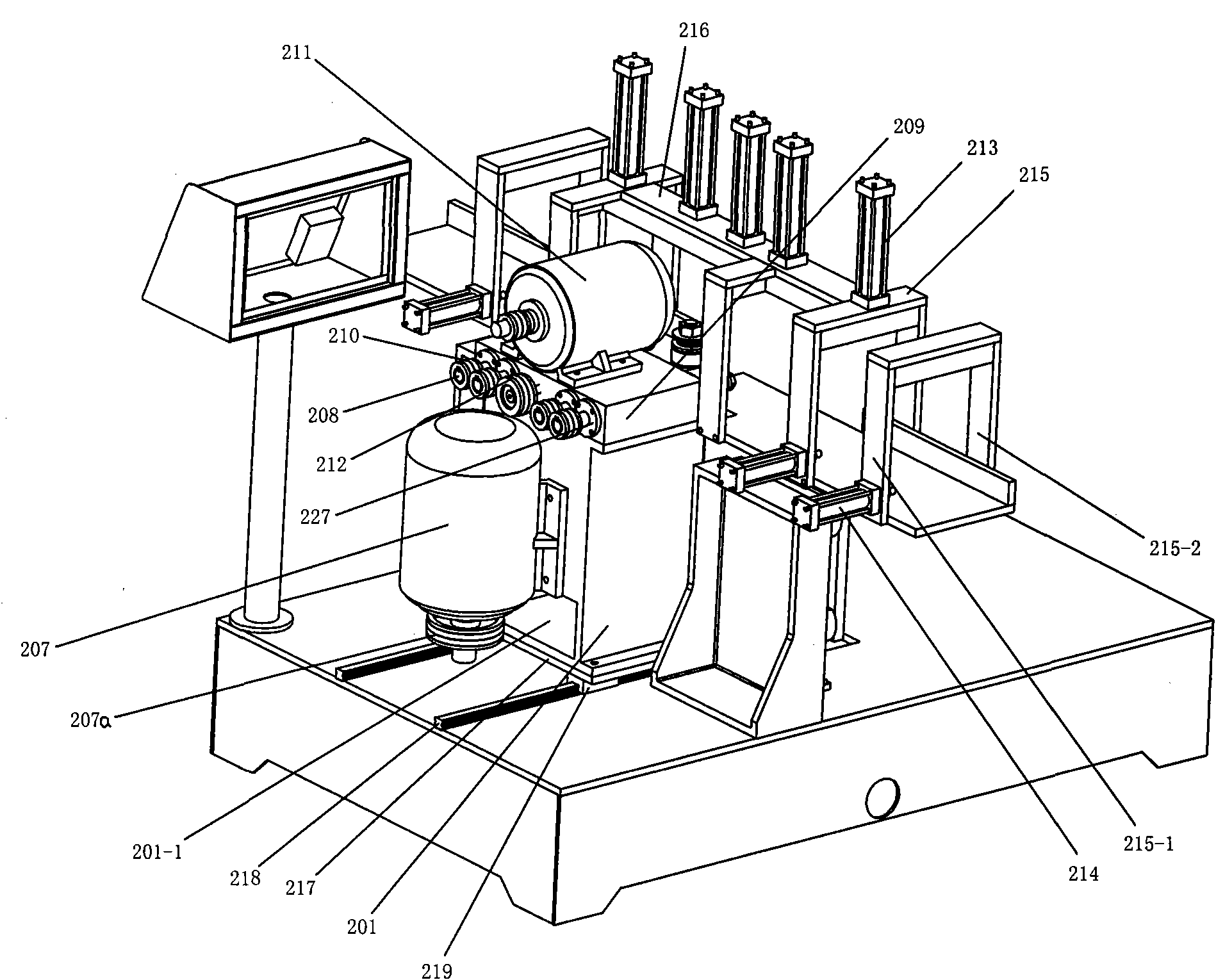

[0030] Such as Figure 1 to Figure 8 Shown, a numerically controlled wooden house tenon machine, is characterized in that: the body 1 is equipped with a drilling and milling device 2, a horizontal milling device 3 with a cylinder stabilizing mechanism, and a numerical control device 4;

[0031]The drilling and milling device 2 includes a base body 201. Left and right pressing workbenches 202, 203 are arranged on both sides of the base body 201. An end milling mechanism and a drilling mechanism are respectively installed on the base body 201. The end milling mechanism includes a vertical milling cutter 204. End milling spindle 205, bearing housing 206 and vertical milling cutter motor 207. The bearing housing 206 is fixedly installed on the front side plate of the seat body 201 between the left and right pressing workbenches 202 and 203. The bearing hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com