Controlling method for coil contacting of hot rolling coiling machine unloading trolley

A coiler and hot-rolled coil technology, which is applied to rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as damage, harsh environment, and poor quality of detection components, and achieve the effect of reducing accident rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Take the 1# coil unloading trolley of the hot rolling 1780 production line, and the diameter of the produced steel coil is 2007mm as an example

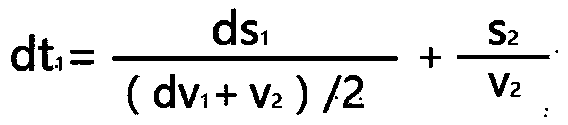

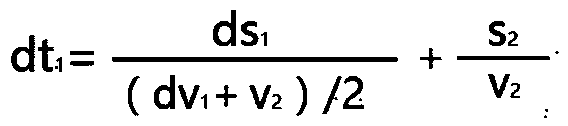

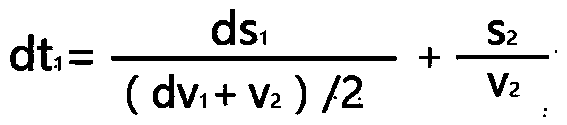

[0039] A control method for coil unloading trolley connection of a hot rolling coiler, the specific steps are as follows:

[0040] 1) Make a calibration program to calculate the low-speed lifting speed and high-speed rising speed of the unloading trolley

[0041] When the coil unloading trolley is driven to the coiler and the auxiliary roll in the coiler is opened, the lifting speed is measured. The unloading trolley operates at a low speed, and the coil unloading trolley rises from the lowest position to the highest position at a low speed. The low-speed rising speed V is calculated by the rising stroke and rising time. 3 65mm / s; after that, the unloading trolley descends back to the lowest position at a low speed, and calculates the low speed descending speed V through the descending stroke and descending time 4 It is 48mm / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com