Environment-friendly floor and manufacture method thereof

A production method and flooring technology, applied in floor coverings, chemical instruments and methods, layered products, etc., can solve the problems of unsatisfactory purification effect, high manufacturing cost, and low purification efficiency, and achieve convenient splicing, good effect, and improved The effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

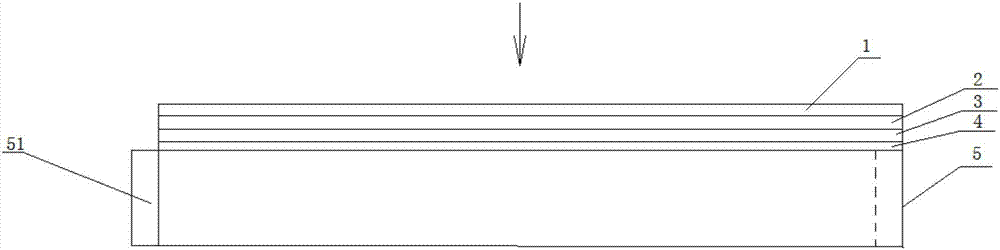

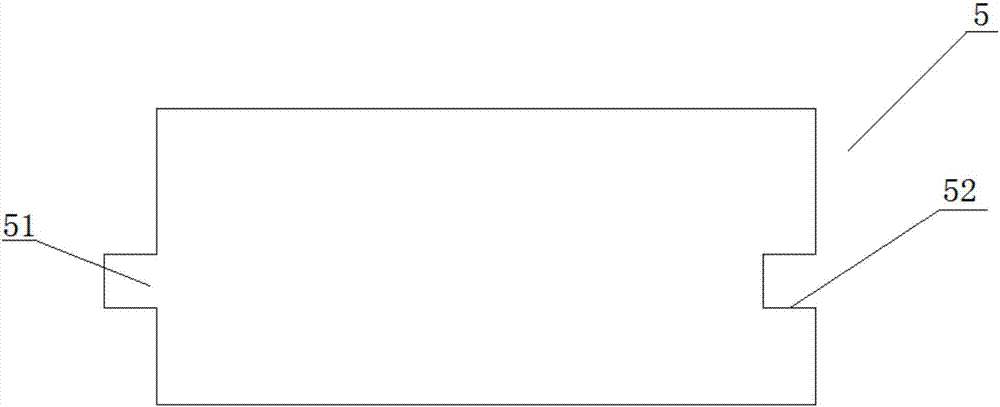

[0044] like Figure 1-Figure 2 As shown, a kind of environmental protection floor, comprises the nano photo-oxygen catalyst layer 1 that is arranged and combined together from top to bottom successively, wear-resisting hardening layer 2, pattern layer 3, base material layer 5, the base material layer 5 The sides are all laid with a negative oxygen ion layer (not shown in the figure), the lower surface of the base material layer 5 is provided with an antibacterial and mildew-proof layer (not shown in the figure), and the pattern layer 3 is a printed pattern plate, Any one of wood veneer, thermal transfer layer, and 3D printing layer, when the pattern layer 3 is a printed pattern plate or wood veneer, an adhesive layer 4 is provided between the base material layer 5 and the pattern layer 3 .

[0045] Further, the nano-photonic oxygen catalyst layer 1 is a nano-titanium dioxide layer.

[0046] Further, the antibacterial and antifungal layer is a composite nano-silver ion layer....

Embodiment 2

[0070] In the present embodiment, in the step (1.1) of the production method of the environmental protection floor, the molding material of the base material layer 5 includes 49 parts of PVC, 11 parts of calcium powder, and 21 parts of carbon powder in parts by weight. , 3 parts of calcium zinc stabilizer, 2 parts of lubricant, 2 parts of modifier, 2 parts of flame retardant, 10 parts of plant fiber, 1 part of foaming agent, 2 parts of foam regulator, 2 parts toughening agent. Other than that, other contents are the same as those in Embodiment 1.

Embodiment 3

[0072] In the present embodiment, in the step (1.1) of the production method of the environmental protection floor, the molding material of the base material layer 5 includes 55 parts of PVC, 50 parts of calcium powder, and 35 parts of carbon powder in parts by weight. , 3 parts of calcium zinc stabilizer, 2.5 parts of lubricant, 2 parts of modifier, 8 parts of flame retardant, 20 parts of plant fiber, 2 parts of foaming agent, 2 parts of foam regulator, 4 parts toughening agent. Other than that, other contents are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com