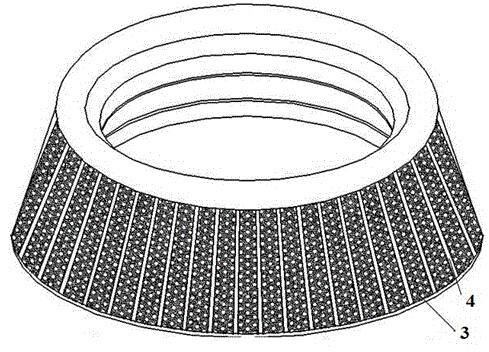

Method for manufacturing cellular ceramic-metal composite vertical mill roller

A technology of metal composite materials and honeycomb ceramics, which is applied in the field of preparation of honeycomb ceramic-metal composite vertical grinding rollers, can solve the problems of delamination, easy occurrence of defects, brittle fracture of grinding rollers, etc., so as to reduce production costs and avoid The effect of crack initiation and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the honeycomb ceramic-metal composite vertical mill roller, its specific steps are as follows:

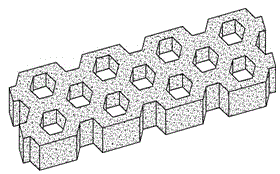

[0047] Step 1. Preparation of honeycomb porous ceramic prefabricated body: First, mix ceramic particles, pore-forming agent and binder at a ratio of 100:3:15 and add them evenly into the mold to prepare a honeycomb porous prefabricated body, then raise the temperature to 500°C for 2 hours The pore-forming agent in the porous ceramic preform is exerted to obtain a honeycomb porous ceramic preform, and the structure diagram of the honeycomb porous ceramic preform is as follows image 3 Shown; wherein the ceramic particles are zirconium corundum, the particle size is 2mm; the pore-forming agent is polyoxymethylene, the particle size is 0.5mm; the binder is a mixture of aluminate cement and silica sol with a mass ratio of 5:10;

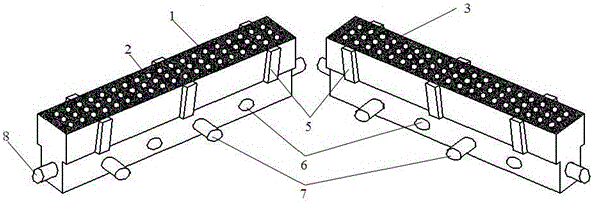

[0048] Step 2. Prepare a honeycomb ceramic-metal composite wear-resistant insert from the honeycomb porous ceramic preform in...

Embodiment 2

[0061] The preparation method of the honeycomb ceramic-metal composite vertical mill roller, its specific steps are as follows:

[0062] Step 1. Preparation of honeycomb porous ceramic prefabricated body: First, mix ceramic particles, pore-forming agent and binder at a ratio of 100:3:15 and add them evenly into the mold to prepare a honeycomb porous prefabricated body, then raise the temperature to 500°C for 2 hours The pore-forming agent in the porous ceramic preform is exerted to obtain a honeycomb porous ceramic preform, and the structure diagram of the honeycomb porous ceramic preform is as follows image 3 Shown; wherein the ceramic particles are zirconium corundum, the particle size is 2mm; the pore-forming agent is polyoxymethylene, the particle size is 0.5mm; the binder is a mixture of aluminate cement and silica sol with a mass ratio of 5:10;

[0063] Step 2. Prepare a honeycomb ceramic-metal composite wear-resistant insert from the honeycomb porous ceramic preform in...

Embodiment 3

[0076] The preparation method of the honeycomb ceramic-metal composite vertical mill roller, its specific steps are as follows:

[0077] Step 1. Preparation of honeycomb porous ceramic prefabricated body: Firstly, ceramic particles, pore-forming agent and binder are mixed evenly at a ratio of 100:1:.6 and added into the mold to prepare a honeycomb porous prefabricated body. The structure diagram of the honeycomb porous ceramic prefabricated body is as follows image 3 As shown, then heat up to 300°C for 2 hours to develop the pore-forming agent in the honeycomb porous ceramic preform to obtain a honeycomb porous ceramic preform; wherein the ceramic particles are titanium carbide with a particle size of 1mm; the pore-former is polystyrene with a particle size of 0.5mm; the binder is a mixture of sodium silicate and distilled water with a mass ratio of 5:1;

[0078] Step 2. Prepare a honeycomb ceramic-metal composite wear-resistant insert from the honeycomb porous ceramic prefor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com