Quick installation device for self-locking inward inclined type strain sensor

A technology of strain sensor and installation device, applied in the direction of measurement device, mechanical device, mechanical measurement device, etc., can solve the problems of easily damaged sensor, nut consumption, improper operation, etc., to ensure measurement accuracy and work efficiency, improve effective performance and accuracy, avoid unusable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

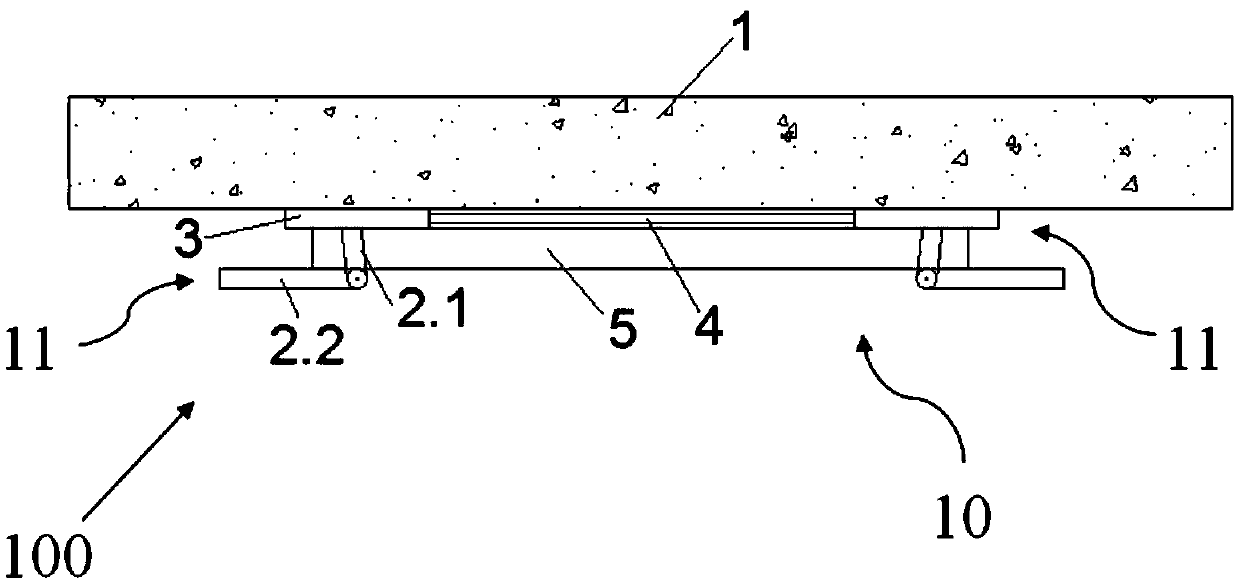

[0027] figure 1 It is a structural schematic diagram of a bridge monitoring device according to Embodiment 1 of the present invention.

[0028] Such as figure 1 As shown, the bridge monitoring device 100 of this embodiment is used to detect the bridge 1 as the structure to be tested, and includes a strain sensor 5 and a quick installation device 10 for a self-locking inclination strain sensor.

[0029] Wherein, the strain sensor 5 is in the shape of a cuboid, and a through fixing hole is provided on each of its two ends in the length direction;

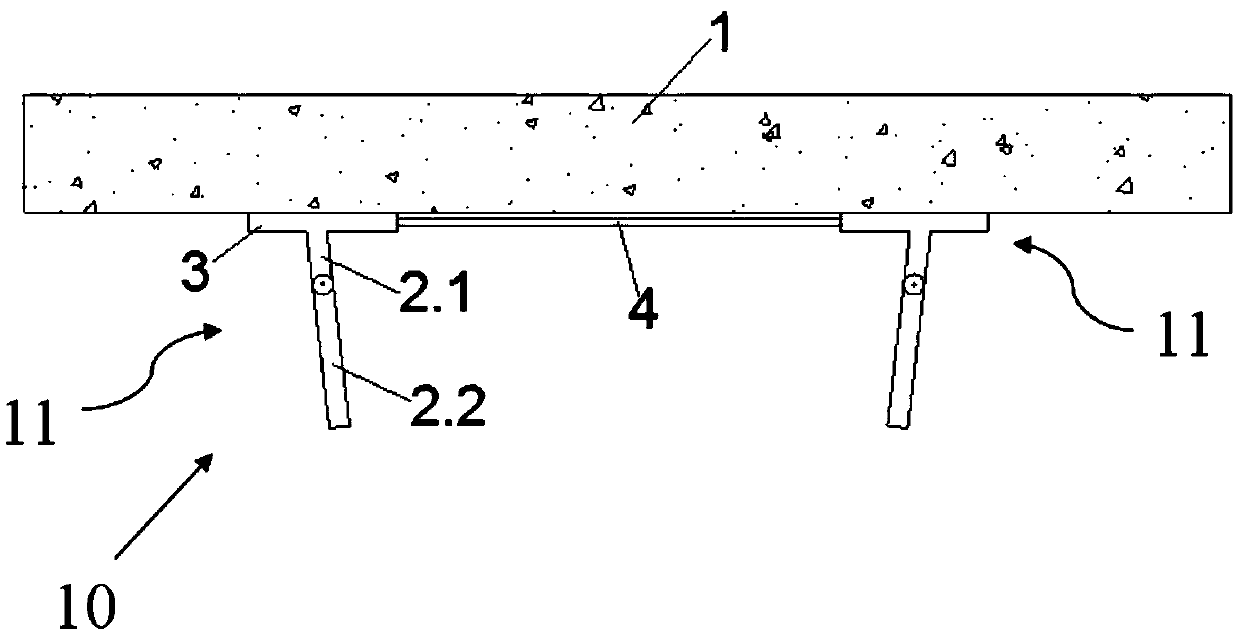

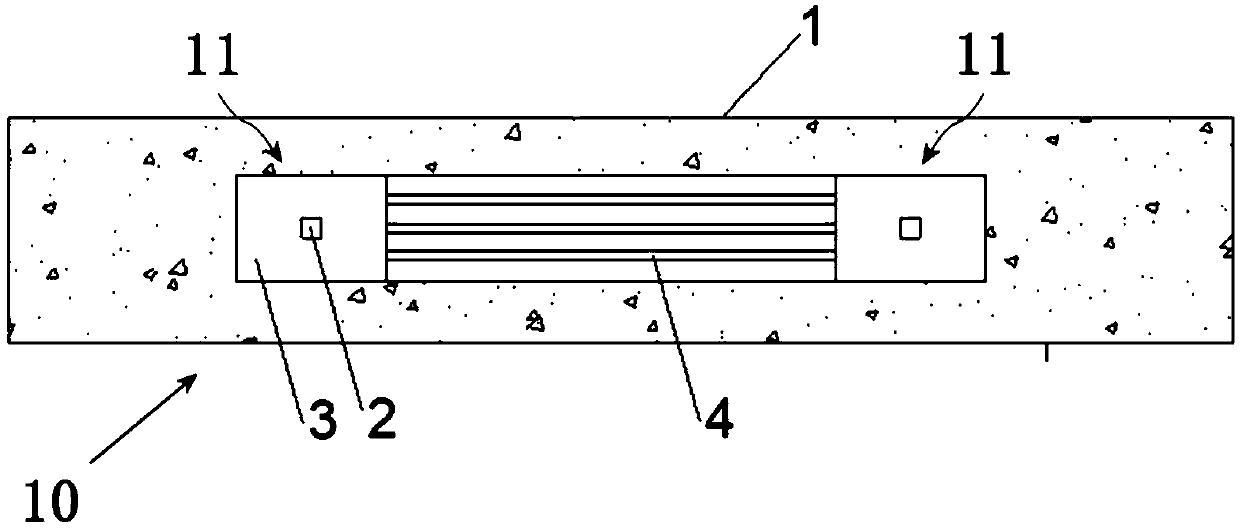

[0030] figure 2 It is a schematic structural diagram of a self-locking inward-facing strain sensor quick installation device according to Embodiment 1 of the present invention, image 3 It is a schematic bottom-view structure diagram of the self-locking inclining strain sensor quick installation device according to Embodiment 1 of the present invention.

[0031] Such as figure 2 and image 3 As shown, the self-locking inclinat...

Embodiment 2

[0058] In the second embodiment, the same structures as those in the first embodiment are assigned the same symbols and the same descriptions are omitted.

[0059] The structural difference between the second embodiment and the first embodiment lies in the connection structure between the upper link 2.1 and the lower link 2.2.

[0060] Figure 6 It is an enlarged schematic view of the connection structure between the upper link and the lower link in the second embodiment of the present invention.

[0061] Such as Figure 6 As shown, the upper connecting rod 2.1 and the lower connecting rod 2.2 in this embodiment are also rotationally connected through the rotating shaft, and the upper connecting rod 2.1 is also provided with a recessed part 2.1.1 at the position of the rotating shaft.

[0062] Different from Embodiment 1, the protrusion 2.2.2 provided on the lower link 2.2 is a circular protrusion corresponding to the recess 2.1.1, and the inner wall of the recess 2.1.1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com