Wooden foot bath bucket and production process thereof

A production process and a technology for a foot bath bucket, which is applied to wood processing appliances, bathtubs, showers, etc., can solve the problems of strict requirements, high production costs, cumbersome production processes, etc., and achieve good thermal insulation effect, save manpower, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

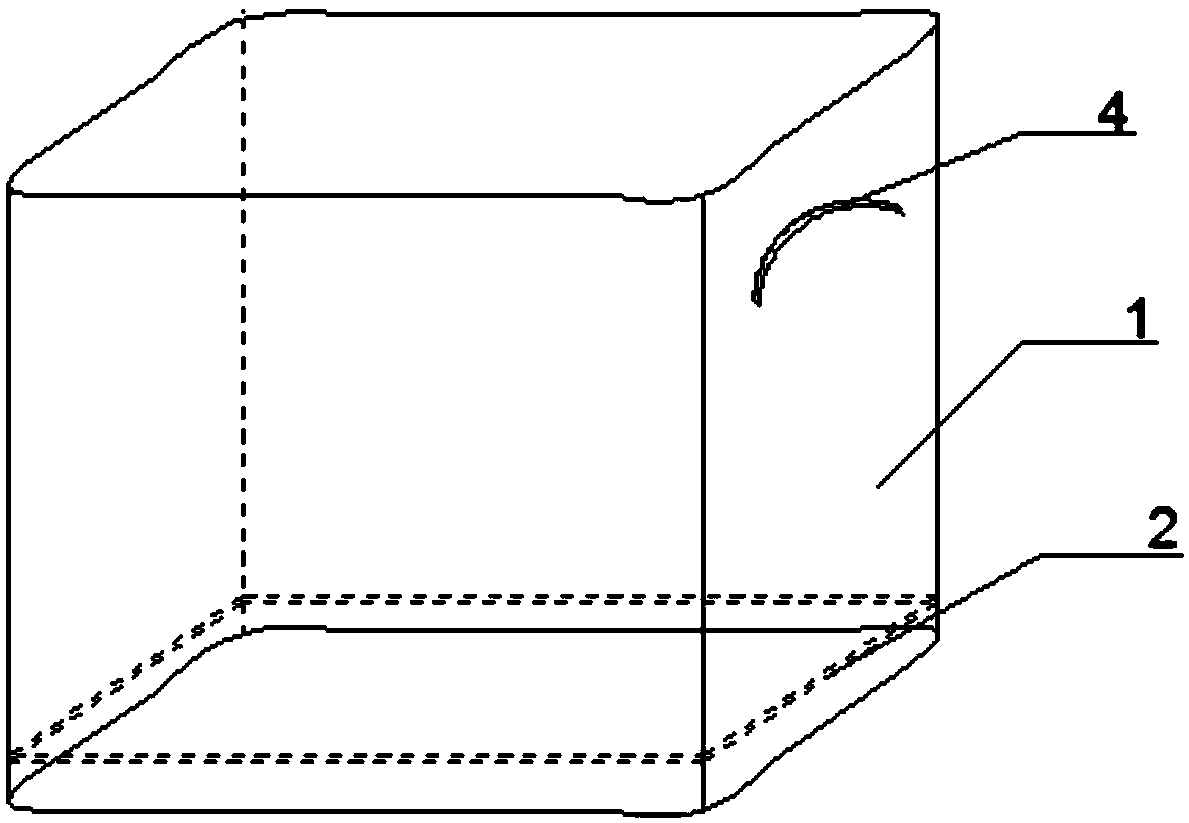

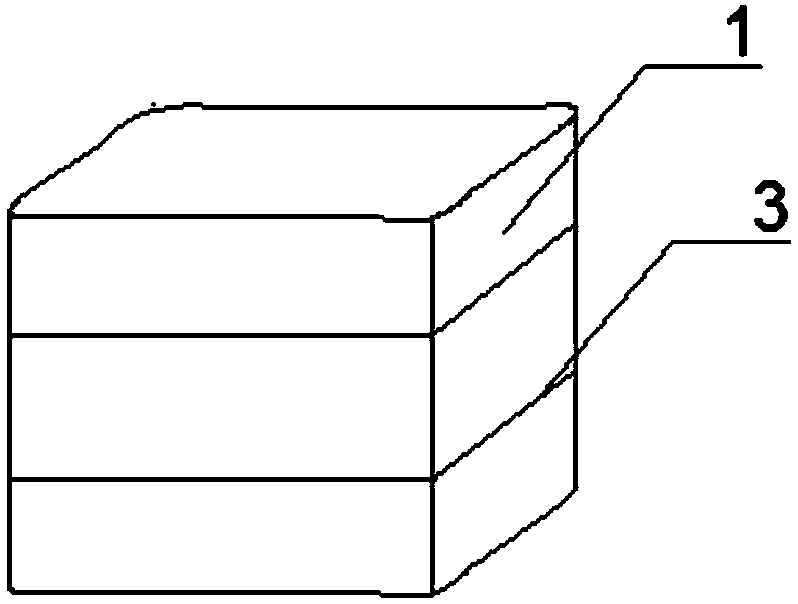

[0027] Such as figure 1 with figure 2 Shown: a wooden foot bath barrel, including a barrel bottom, a barrel wall and a barrel hoop, the inner surface of the lower end of the barrel wall is provided with a groove, the groove is arranged along the circumference of the barrel wall, and the barrel bottom is inserted into the groove The inner part is fixedly connected with the barrel wall, and the barrel hoop is arranged along the circumference of the outer surface of the barrel wall.

[0028] The production technology of described wooden footbath tub, comprises the following steps:

[0029] (1) select three small boards and polish to obtain three identical rectangular small boards; the long sides of two adjacent small boards in the three small boards are fixedly connected to form a rectangular plank;

[0030] (2) Repeat the operation of step (1) to get four rectangular planks for subsequent use;

[0031] (3) select four planks to polish to obtain four arc-shaped planks, the he...

Embodiment 2

[0036] Such as figure 1 with figure 2 Shown: a wooden foot bath barrel, including a barrel bottom, a barrel wall and a barrel hoop, the inner surface of the lower end of the barrel wall is provided with a groove, the groove is arranged along the circumference of the barrel wall, and the barrel bottom is inserted into the groove The inner part is fixedly connected with the barrel wall, and the barrel hoop is arranged along the circumference of the outer surface of the barrel wall.

[0037] The production technology of described wooden footbath tub, comprises the following steps:

[0038] (1) Select three small plates to polish to obtain three identical rectangular small plates; the long sides of two adjacent small plates in the three small plates are connected by rivets; the two ends of the rivets are respectively inserted into the adjacent two On the contacting surface of the small boards, the number of the rivets is three, and the three rivets are evenly distributed on the...

Embodiment 3

[0045] Such as figure 1 with figure 2 Shown: a wooden foot bath barrel, including a barrel bottom, a barrel wall and a barrel hoop, the inner surface of the lower end of the barrel wall is provided with a groove, the groove is arranged along the circumference of the barrel wall, and the barrel bottom is inserted into the groove The inner part is fixedly connected with the barrel wall, and the barrel hoop is arranged along the circumference of the outer surface of the barrel wall.

[0046] The production technology of described wooden footbath tub, comprises the following steps:

[0047] (1) Select three small plates to polish to obtain three identical rectangular small plates; the long sides of two adjacent small plates in the three small plates are connected by rivets; the two ends of the rivets are respectively inserted into the adjacent two On the contacting surface of the small boards, the number of the rivets is three, and the three rivets are evenly distributed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com