Assembly-type building and assembling method thereof

A kind of prefabricated and architectural technology, which is applied in the direction of architecture and building construction, can solve the problems of cumbersomeness, low strength of building structure, and laborious, etc., and achieve the effect of accelerated construction, fast assembly, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

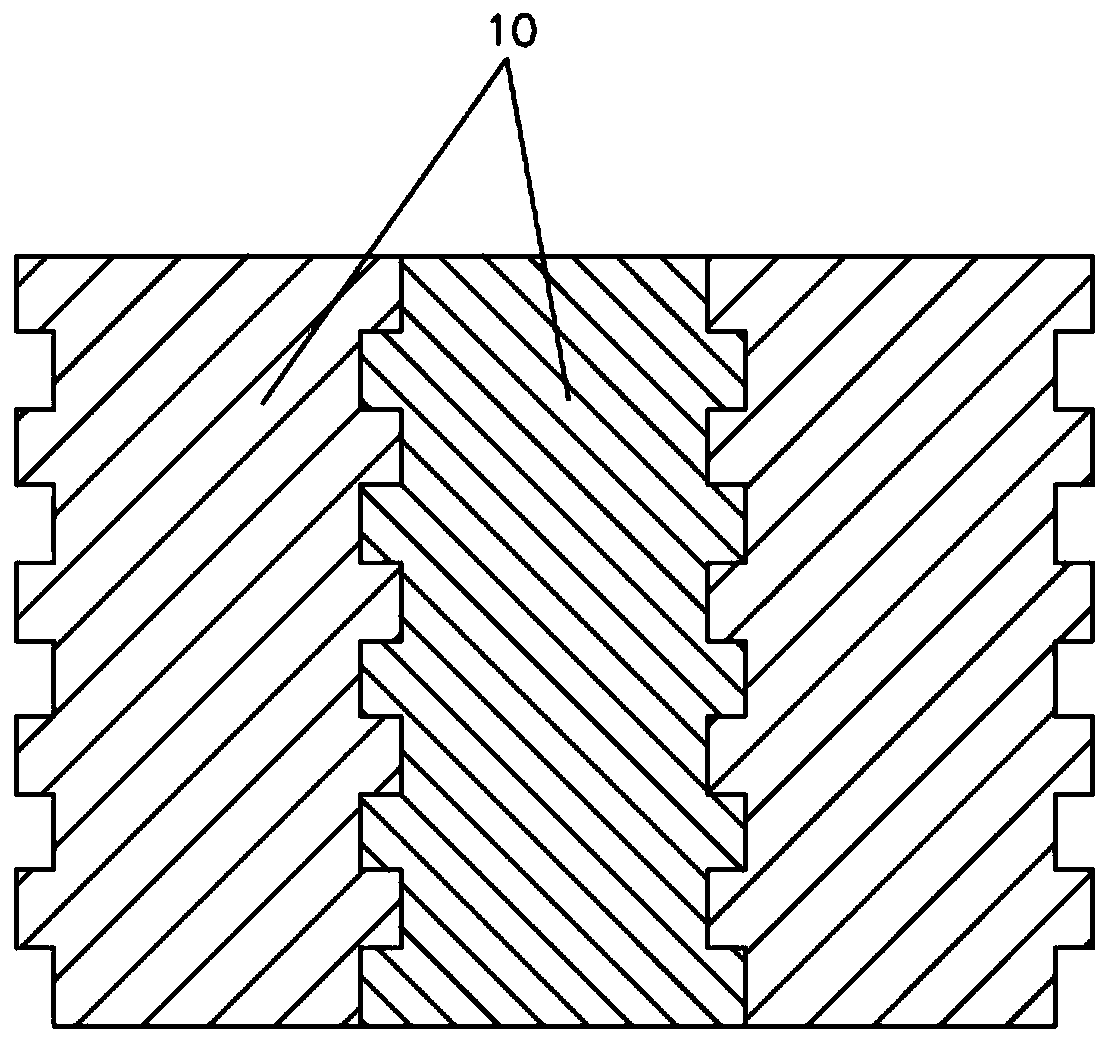

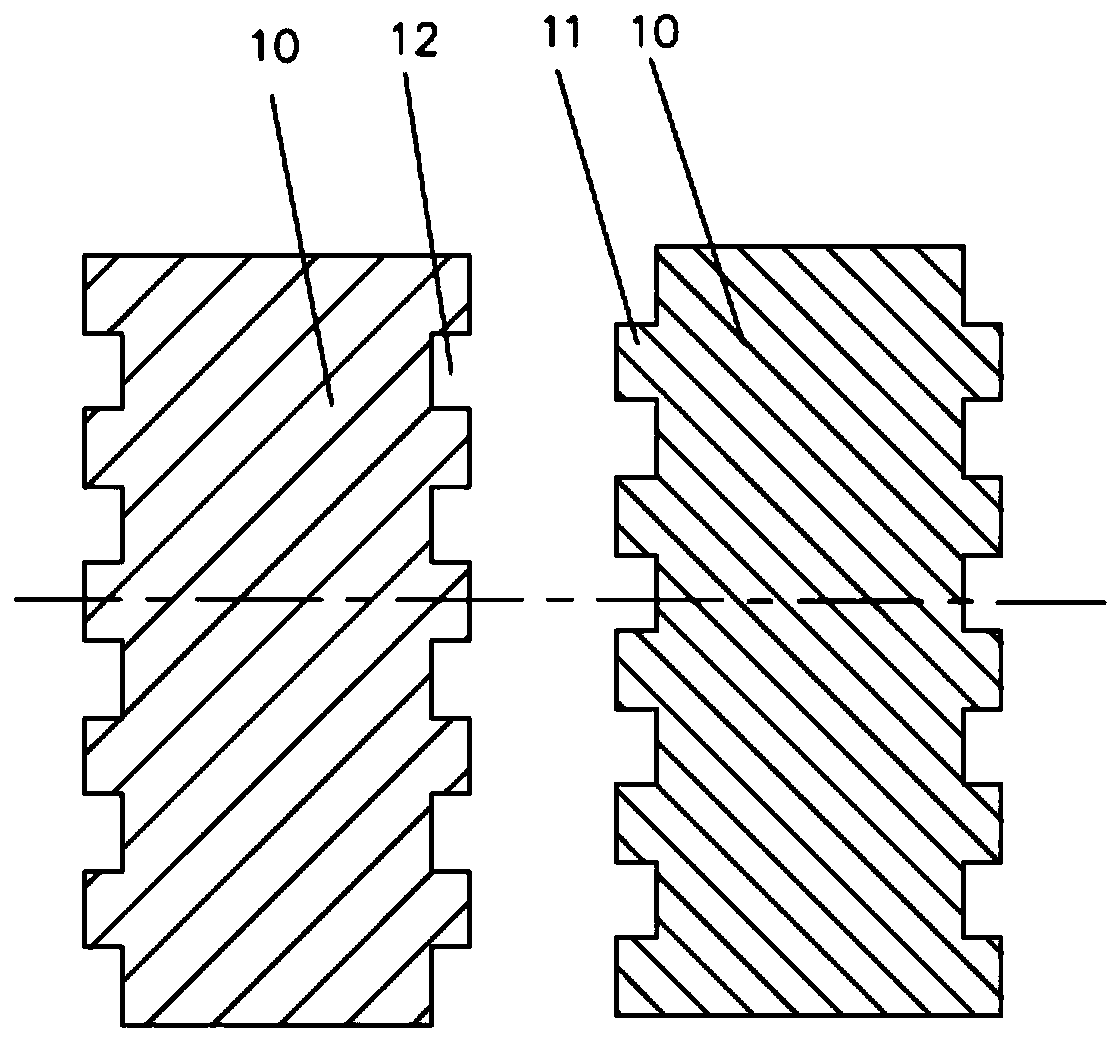

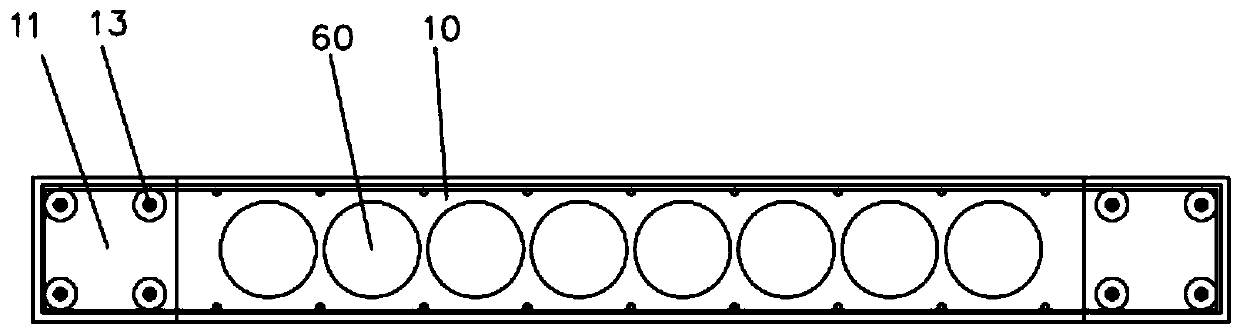

[0037] A prefabricated building, such as figure 1 , 2 As shown in , 3, it includes a plurality of vertically arranged wall panels and floor slabs arranged at the top of the wall panels, and each adjacent two wall panels are connected by prefabricated components; wherein the wall panels include a plurality of mutually butted prefabricated panels 10, One side of each prefabricated panel 10 is vertically fixed with a plurality of protrusions 11 at equal intervals, and the other side of the prefabricated panel 10 is provided with a plurality of grooves 12 at equal intervals, on the upper and lower side walls of each groove 12 A through hole is provided, and each protrusion 11 is vertically provided with a through hole. After the two prefabricated panels 10 are docked, each protrusion 11 on one of the prefabricated panels 10 can be plugged into the other prefabricated panel 10 respectively. In each groove 12 of the board 10, and the through hole on each groove 12 is on the same ax...

Embodiment 2

[0048] A method for assembling a prefabricated building, comprising the following steps,

[0049] S1, each prefabricated panel 10 is spliced together, so that the protrusion 11 on each prefabricated panel 10 is inserted into the groove 12 of another prefabricated panel 10, and then the first steel bar 13 is extended into each inserted into each The through hole of the bump 11 and the through hole of each groove 12, and pour grout into the through hole of each bump 11 and the through hole of the groove 12 along the first steel bar 13 to form a wallboard ;

[0050] S2, fix the finished wallboard to the designated position of the foundation, install the L-shaped assembled component 30 at the corner of the wallboard, and insert each plug 32 into the groove 12 of the prefabricated panel 10 at the edge of the wallboard , and insert the plug 32 on the other side of the L-shaped assembly member 30 into the groove 12 of the prefabricated panel 10 at the edge of another wallboard, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com