Constant tension jointing device for strip-shaped non-woven fabric substrate

A technology of non-woven fabric base and splicing device, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., which can solve the impact on the quality of machine-made products and the stability of equipment, and affect the production efficiency and economic benefits of manufacturers. Increased product instability factors and other issues, to achieve the effect of stable splicing, less waste products, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

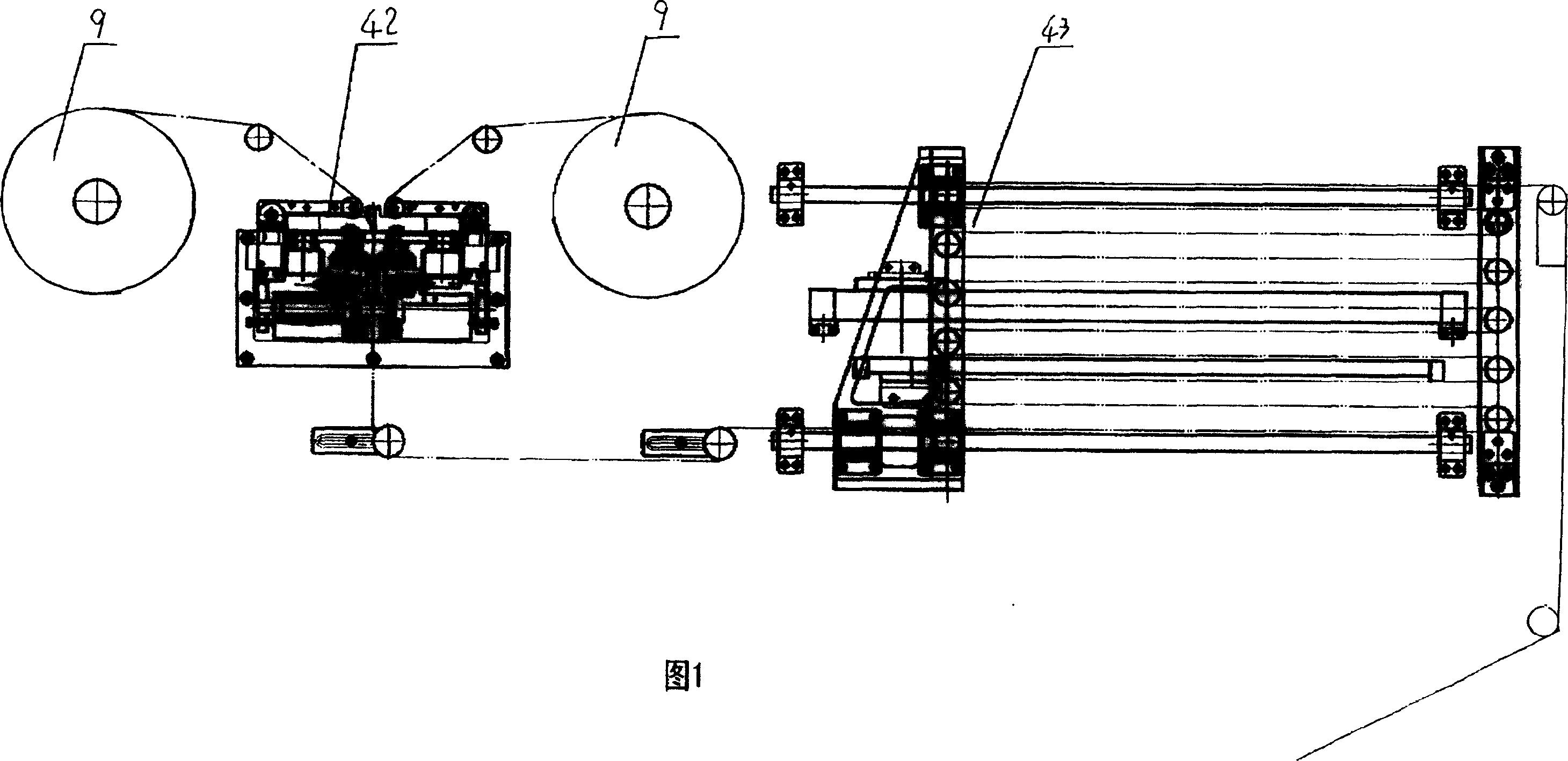

[0034] The constant tension splicing device for the strip-shaped non-woven substrate includes a splicing mechanism 42, a constant tension mechanism 43 and a frame stand, as shown in FIG. 1 .

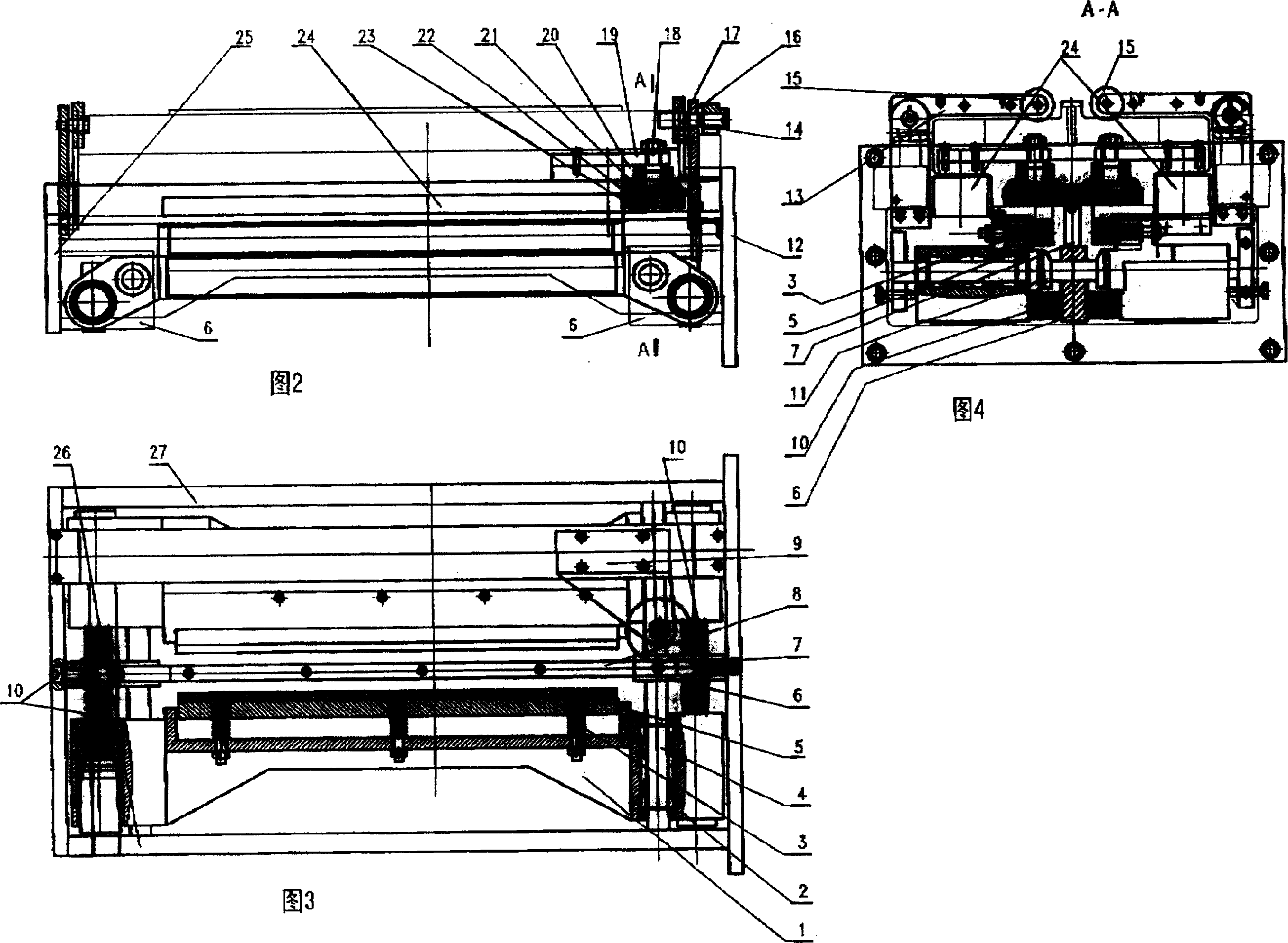

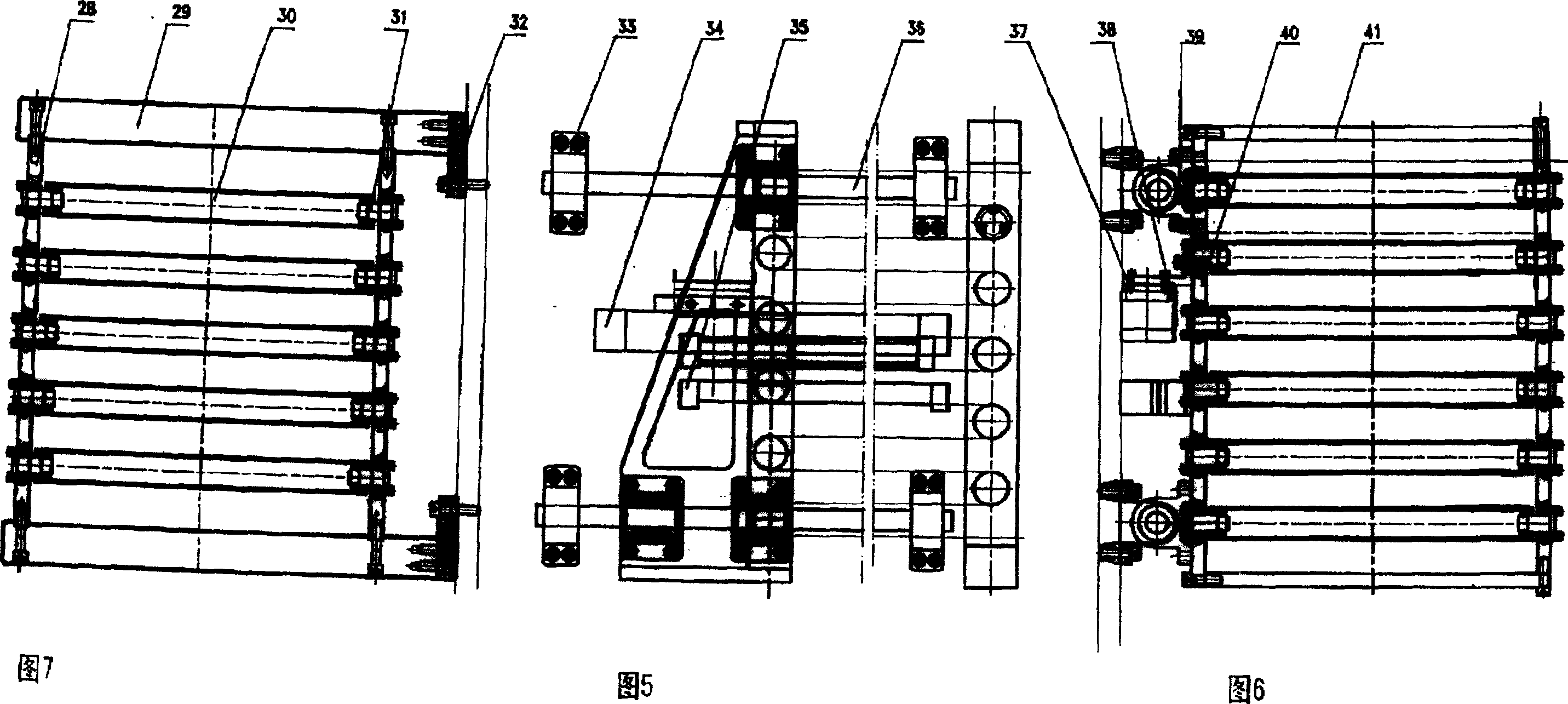

[0035] The splicing mechanism includes a frame, an anvil assembly, a moving bracket assembly, a cutting knife assembly and a safety door assembly, see Fig. 2, Fig. 3, Fig. 4, Fig. 8 and Fig. 9.

[0036] Frame is made up of base plate 12, front plate 25, left side plate 27 and right side plate 26, and base plate 12 is fixedly installed on the frame vertical plate.

[0037] Base plate 12 and front plate 25 corresponding side middle parts are respectively fixedly installed middle support block 6, two middle support block 6 tops are installed strip anvil 8 by knife seat 7.

[0038] The left and right side plates 27, 26 on both sides of the two intermediate support blocks 6 are respectively equipped with cylinders 2 by the guide shaft 4, and the four cylinders 2 and the intermediate support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com