Hydrogen gas storage alloy reactor

A reactor and reaction vessel technology, applied in gas/liquid distribution and storage, non-metallic elements, metal hydrides, etc., can solve the problems of slow hydrogen discharge, slow reaction speed, insufficient reaction, etc. The effect of verticality, improving reactivity, and saving production unit price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

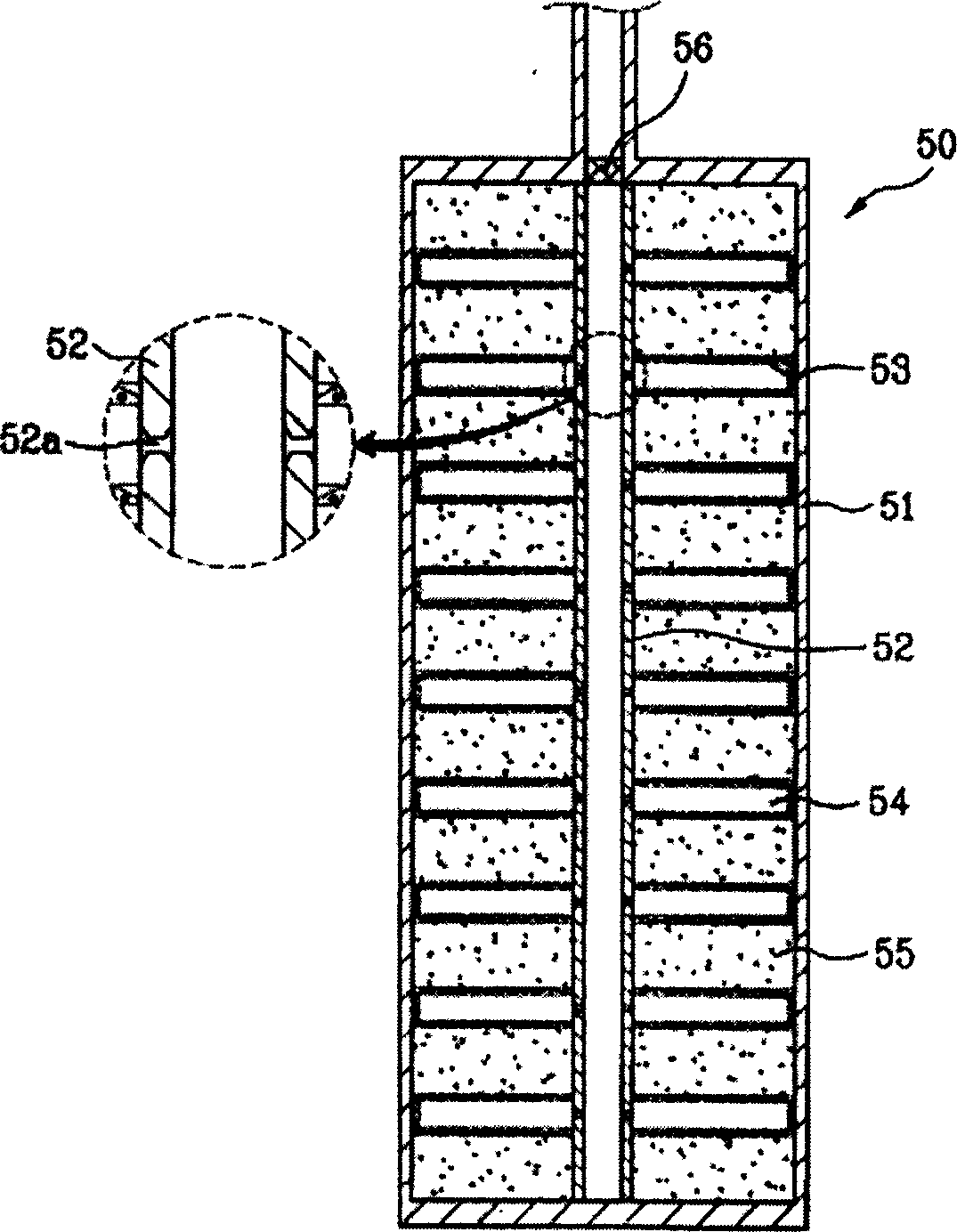

[0043] The first example of the hydrogen storage alloy reactor in the present invention is illustrated below, with reference to the attached image 3 And accompanying drawing 5 to illustrate.

[0044] image 3 A longitudinal sectional view showing a first example of a hydrogen storage alloy reactor in the present invention, Figure 4a hint image 3 The oblique view of the network pore structure, Figure 4b prompt will Figure 4a The cross-sectional view of the mesh holes cut in the shortest direction.

[0045] Refer to attached image 3 It can be seen that the reactor 50 is composed of a reaction vessel 51 , a hydrogen gas introduction pipe 52 , a mesh hole 53 , and a hydrogen storage alloy 55 .

[0046] The hydrogen gas introduction pipe 52 is inserted into the inside of the reaction vessel 51, and a plurality of hydrogen gas inflow grooves 52a are formed to connect the inside and the outside of the hydrogen gas introduction pipe.

[0047] The hydrogen gas introduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com