A patterned bacterial cellulose film and its preparation method and application

A bacterial cellulose film and patterning technology, applied in medical science, prosthesis, etc., can solve the problems of long culture time, low fidelity, limited pattern height of patterned cellulose film, etc., and achieve clear pattern , high pattern fidelity, simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation method of patterned polydimethylsiloxane (PDMS) functional sponge

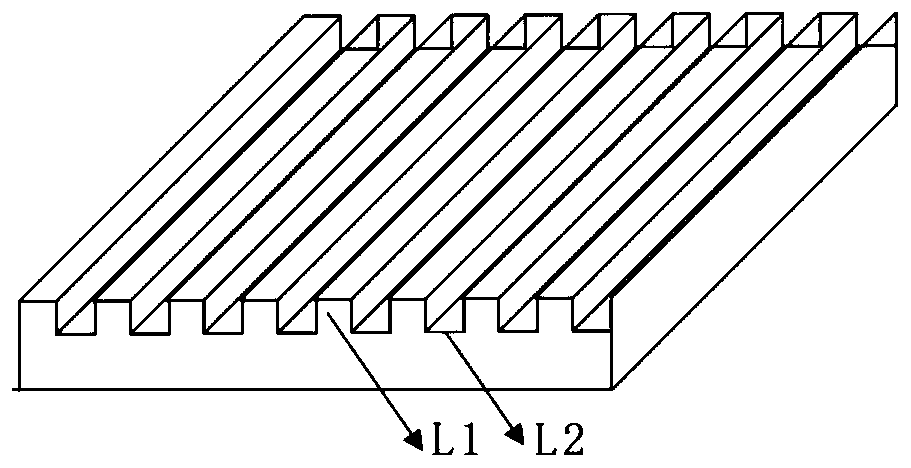

[0031] (1) Preparation of the patterned positive mold: use a glue spreader to evenly spread a layer of SU-8 photoresist (GM1070) on the dried silicon wafer, and set the number of revolutions of the glue spreader: the starting speed is 500r / min, the time is 40S; the speed of the second step is 2300r / min, and the time is 60S. A SU-8 coating with a thickness of about 25 μm was thus obtained on the silicon wafer. The silicon wafer is pre-baked, exposed (ultraviolet), post-baked, developed with a developer, and hardened to obtain the SU-8 positive mold. The pattern of the male mold can be square, strip, circle, etc.

[0032] (2) Preparation of PDMS sponge model: PDMS (Sylgard 184) prepolymer and curing agent (Sylgard 184) were mixed at a mass ratio of 10:1 and stirred evenly. Take the mixture of PDMS pre-polymerization liquid and curing agent, water, and liquid paraffin oil ...

Embodiment 2

[0033] Embodiment 2: the preparation method of patterned polydimethylsiloxane (PDMS) functional sponge

[0034] (1) Preparation of the male mold of the millimeter-scale channel: cut capillaries with a diameter of 2 mm into appropriate lengths, arrange them evenly and fix them on the silicon wafer with secondary polishing, and use them as the male mold of the millimeter-scale channel.

[0035] (2) Preparation of PDMS sponge model: PDMS (Sylgard 184) prepolymer and curing agent (Sylgard 184) were mixed at a mass ratio of 10:1 and stirred evenly. Take the mixture of PDMS pre-polymerization solution and curing agent, water, and liquid paraffin oil and carry out thorough mixing, stirring and emulsification according to the mass ratio of 5:35:7.5. Pour the emulsified mixed solution on the surface of the male mold (thickness is 2-3mm), let it stand for curing first, then put it into an oven at 65°C to heat and cure for 2 hours, and after the PDMS mixture is cured, separate it from th...

Embodiment 3

[0036] Embodiment 3: the preparation method of the bacterial cellulose membrane of patterning

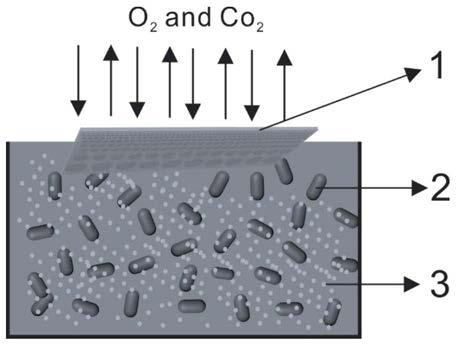

[0037](1) The micron-scale patterned PDMS sponge model obtained in Example 1 is sterilized and placed on the surface containing Acetobacter glucosus culture (preferably the culture medium is inoculated at a volume ratio of 10:1 to the strain), as figure 1 shown.

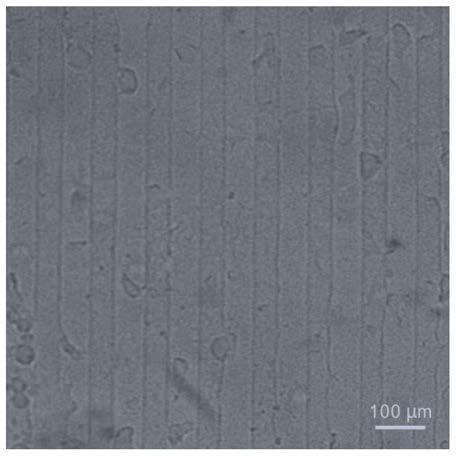

[0038] (2) Place the culture bottle in a sterile incubator for 12-48h (30°C), and tear off the PDMS sponge model to obtain a patterned cellulose membrane, such as image 3 As shown, the prepared micron-scale strip patterned cellulose film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com