Electrostatic spinning patterning collection method and electrostatic spinning apparatus

An electrospinning and patterning technology, which is used in the bundling of newly ejected filaments, filament forming treatment, textiles and papermaking, etc., can solve the problems of complex structure, insufficient graphics and poor controllability of receiving parts. , to achieve the effect of simple control method, good effect and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

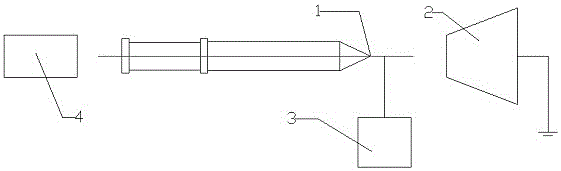

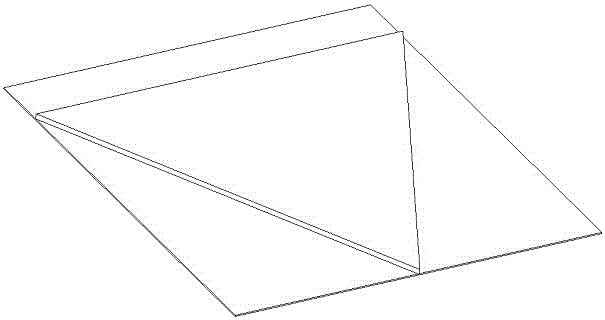

[0025] In this example, see figure 1 with figure 2 , an electrospinning device, which is composed of a micropump 4, a liquid supply extrusion device 1, a receiving part 2 and a high-voltage power supply 3, and a device with a The fixed-shaped strong soft magnetic plate makes the surface area part of the receiving part 2 facing the liquid supply extrusion device 1 and corresponding to the area glued with the strong soft magnetic plate form a set area for collecting fiber aggregates, and adjust the liquid supply extrusion The distance between the outlet of the feeding nozzle of the device 1 and the receiving part 2 is 200-400mm, the feeding nozzle of the liquid feeding extrusion device 1 is connected to the positive pole of the power supply, and the receiving part 2 with a strong soft magnetic plate of a certain shape is connected to the negative pole of the power supply , control the high-voltage power supply 3 to provide a voltage of 10-20kv and adjust the size of the voltag...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, especially in that:

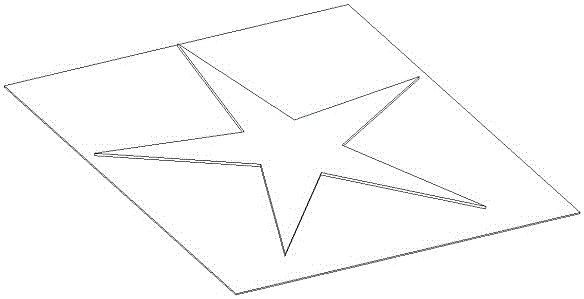

[0034] In this example, see image 3 , an electrospinning patterned collection method, it comprises the following steps:

[0035] a. This step is identical with embodiment one;

[0036] b. Stick the strong soft magnetic plate cut into a five-pointed star on the surface of the receiving part 2 facing away from the liquid supply extrusion device 1, so that the area of the receiving part 2 corresponding to the strong soft magnetic plate glued with the five-pointed star is formed to collect For the five-pointed star setting area of the fiber aggregate, adjust the distance between the liquid supply extrusion device 1 and the receiving part 2 to receive the film to 200mm, connect the supply nozzle of the liquid supply extrusion device 1 to the positive pole of the high-voltage power supply 3, and place the sticky The receiving part 2 of the pentagram-shaped strong soft magnetic plate is conne...

Embodiment 3

[0040] This embodiment is basically the same as the previous embodiment, and the special features are:

[0041] In this example, see Figure 4 , an electrospinning patterned collection method, it comprises the following steps:

[0042] a. This step is identical with embodiment one;

[0043] b. Take the prepared gelatin-sodium alginate bone scaffold, which has high porosity and regular pores, and put the receiving part 2, which has the same shape as the planar projection shape of the gelatin-sodium alginate bone scaffold, with a strong soft magnetic plate. Under the gelatin-sodium alginate bone bracket, a strong soft magnetic plate cut into a set shape is glued to the surface of the receiving part 2 on the side of the liquid supply extrusion device 1, so that the corresponding shape is glued. The area of the receiving part 2 of the strong soft magnetic plate forms a set area for collecting the set shape of the fiber aggregate, adjust the distance between the liquid supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com