Nanocellulose-containing bioinks for 3D bioprinting, methods of making and using the same, and 3D biostructures obtained therefrom

A technology of nanocellulose and bio-ink, which can be used in drug delivery, tissue regeneration, and pharmaceutical formulations, and can solve the problems of non-existence of bio-ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

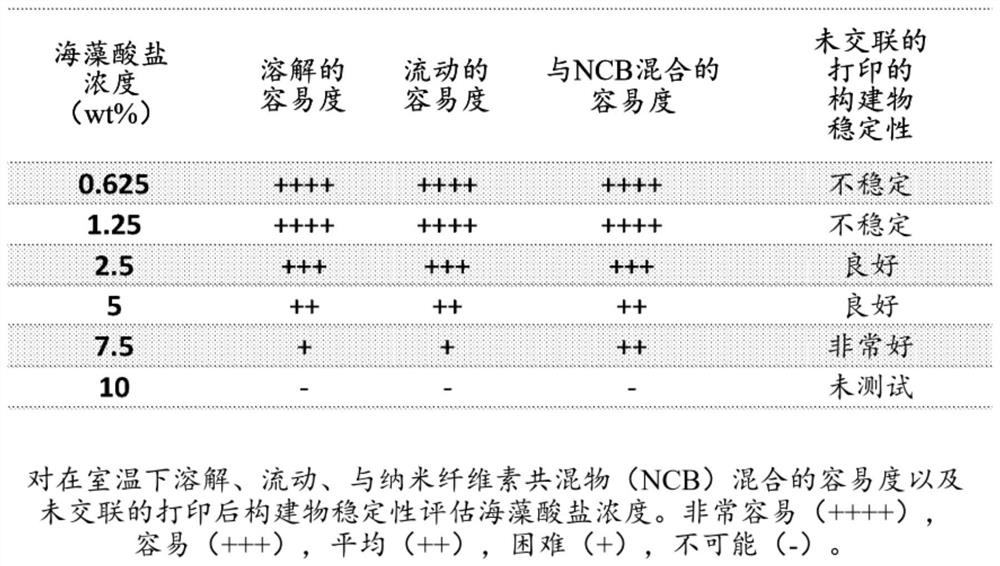

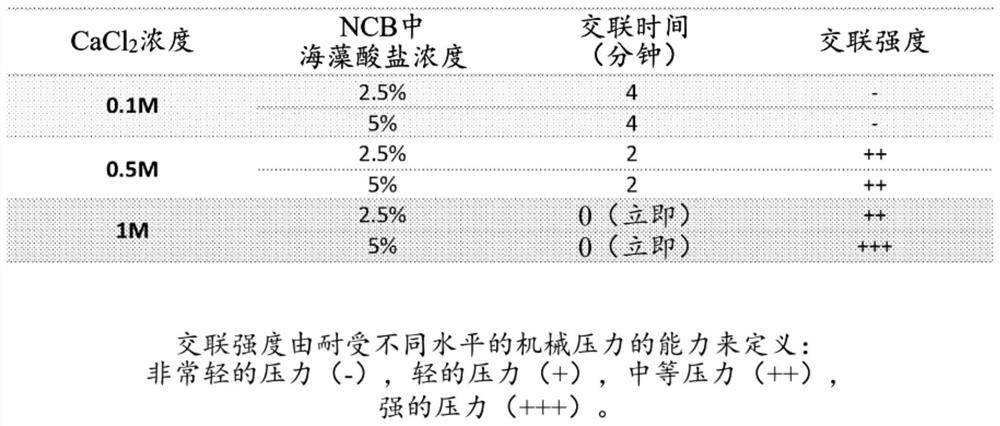

[0322] The bioprintability of crystalline, fibrillated, and blended formulations of nanocellulose was evaluated by evaluating resolution (gridline analysis) and post-printing shape fidelity and rheology (elasticity, viscosity, and shear thinning properties) and comparing these to pure alginate bioinks. Human nasal septal chondrocytes bioprinted an optimized nanocellulose-alginate bioink to determine cytotoxicity, metabolic activity, and biostructural morphology.

[0323] As will be shown in these examples, the disclosed nanocellulose-alginate bioink composition exhibits a high degree of shear thinning with reversible stress-softening behavior, which facilitates post-printing shape fidelity . Bioinks containing a blend of crystalline and fibril nanocellulose exhibited nanoscale as well as microscale roughness for cell survival and differentiation, and maintained the most stable construct volumes in culture. Human nasal septal chondrocytes exhibit high metabolic activity after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com