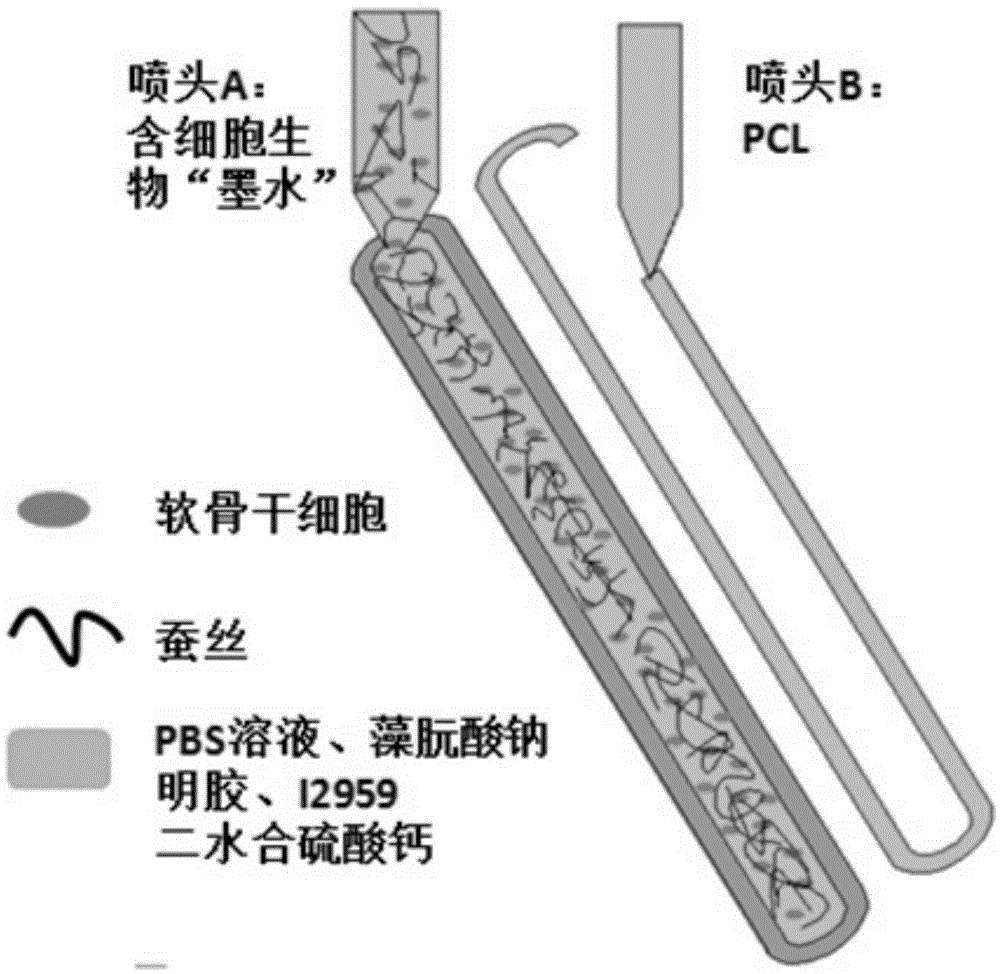

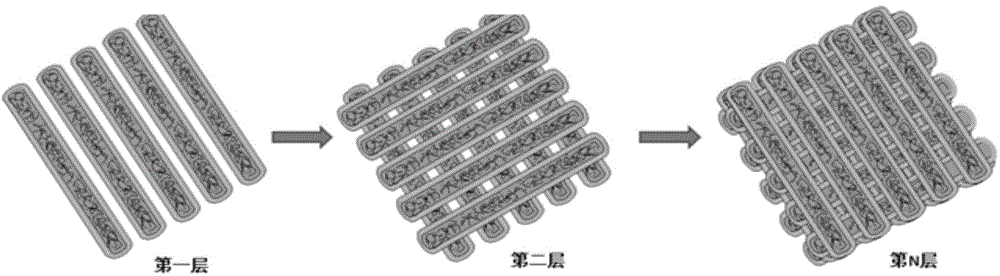

Method for preparing cartilage with high mechanical property based on 3D bioprinting

A bioprinting and cartilage technology, applied in the field of 3D bioprinting, can solve the problems of poor mechanical properties and low cell survival rate, and achieve the effect of improving mechanical properties, excellent mechanical properties, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of silk fiber: Cut the cocoon into fragments of 0.5 cm in length, put the fragments in a sodium carbonate solution with a molar concentration of 0.02M, stir and boil for 40 minutes, rinse the silk three times for 20 minutes, take out the tweezers and dry overnight. Drop the 10.0M lithium bromide solution on the silk and incubate at 70℃ for 3h. Put the cultured silk into a dialysis box and dialyze it in ultrapure water for 24h. Take out the silk solution in the dialysis box and centrifuge twice at 4℃. Next store.

[0023] (2) Preparation of gelatin solution: add 7.0%wt of phosphate buffer to the phosphate buffer, stir continuously at 45°C until the gelatin is completely dissolved, add 1.5mL to the solution while stirring at a speed of 0.5mL / min A methacrylic anhydride solution with a mass concentration of 94% was reacted at 50℃ for 1h, then diluted with 40mL phosphate buffer at 40℃, and then dialyzed with 12000 dialysis membrane in 40℃ deionized water for 1 ...

Embodiment 2

[0029] (1) Preparation of silk fiber: Cut silkworm cocoons into fragments with a side length of 1.0cm, put the fragments in a sodium carbonate solution with a molar concentration of 0.02M, stir and boil for 50min, rinse the silk three times for 20min, take out the tweezers and dry overnight. Drop the 7.0M lithium bromide solution on the silk and incubate at 50℃ for 5h. Put the cultured silk into a dialysis box and dialyze in ultrapure water for 48h. Take out the silk solution in the dialysis box and centrifuge twice at 4℃. Next store.

[0030] (2) Preparation of gelatin solution: add 10.0%wt of phosphate buffer mass gelatin to the phosphate buffer, stir continuously at 60℃ until the gelatin is completely dissolved, add 0.5mL to the solution while stirring at a speed of 1.0mL / min A methacrylic anhydride solution with a mass concentration of 94% was reacted at 50°C for 1 hour, then diluted with 40mL phosphate buffer at 40°C, and then dialyzed with a 14000 dialysis membrane in 40°C ...

Embodiment 3

[0036] (1) Preparation of silk fiber: Cut the cocoon into pieces with a side length of 0.8cm, put the pieces in a sodium carbonate solution with a molar concentration of 0.02M, stir and boil for 30 minutes, rinse the silk three times for 20 minutes, take out the tweezers and dry overnight. Drop the 12.0M lithium bromide solution on the silk and incubate it at 30℃ for 2h. Put the cultured silk into a dialysis box and dialyze it in ultrapure water for 60h. Take out the silk solution in the dialysis box and centrifuge twice at 4℃. Next store.

[0037] (2) Preparation of gelatin solution: add 12%wt of phosphate buffer to the phosphate buffer, stir continuously at 30°C until the gelatin is completely dissolved, and add 1 mL of weight to the solution while stirring at a speed of 0.1mL / min 94% methacrylic anhydride solution, react at 50℃ for 1h, then dilute with 40mL phosphate buffer at 40℃, then dialyzed with 13000 dialysis membrane in 40℃ deionized water for 1 week, and finally use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com