Preparation method of high-purity biapenem

A biapenem, high-purity technology, applied in the field of preparation of pharmaceutical compounds, can solve the problems of reduced purity, difficult separation, difficult recovery, etc., and achieve the effects of reducing the generation of impurities, small reaction volume, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

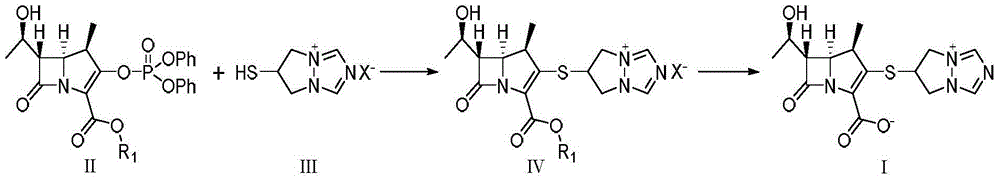

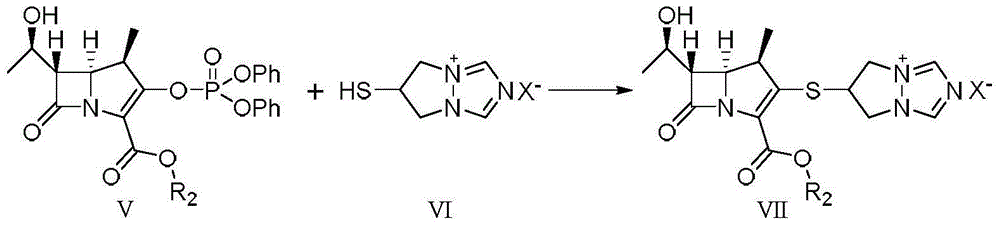

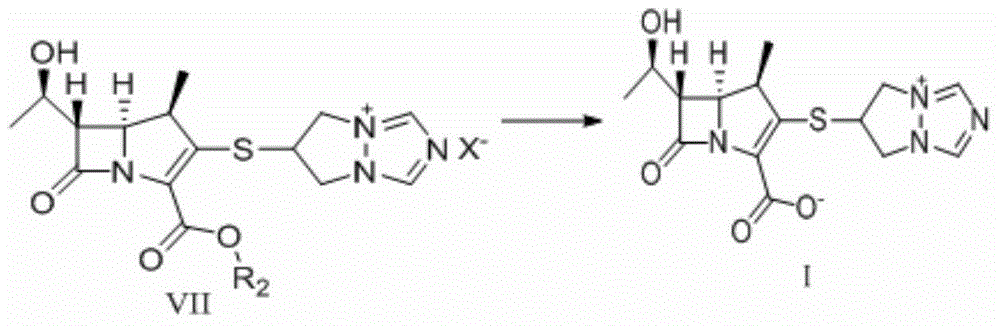

Method used

Image

Examples

Embodiment 1

[0043] 6-[[(4R,5S,6S)-2-[(4-nitrobenzyloxy)carbonyl]-6-[(1R)-1-hydroxyethyl]-4-methyl-7-oxo- 1-Azabicyclo[3.2.0]hept-2-en-3-yl]thio]-6,7-dihydro-5H-pyrazolo[1,2-a][1,2,4]tri Preparation of azol-4-ium chloride (compound of formula VII)

[0044] (4R,5R,6S)-3-(Diphenoxyphosphonooxy)-6-((R)-1-hydroxyethyl)-4-methyl-7-carbonyl-1-azabicyclo [3.2.0] p-nitrobenzyl hept-2-ene-2-carboxylate (compound of formula V) 50.0g, 6-mercapto-6,7-dihydro-5H-pyrazolo[1,2-a Add 18.6g of [1,2,4]triazol-4-ium chloride (compound of formula VI), 23.7g of N,N-dimethylformamide and 11.7g of triethylamine into 400g of acetonitrile, stir and blow nitrogen Protected, stirred at -10 to -15°C for 10 hours, filtered, and dried to give 6-[[(4R,5S,6S)-2-[(4-nitrobenzyloxy)carbonyl]-6-[(1R)- 1-Hydroxyethyl]-4-methyl-7-oxo-1-azabicyclo[3.2.0]hept-2-en-3-yl]thio]-6,7-dihydro-5H-pyridine Azolo[1,2-a][1,2,4]triazol-4-ium chloride (compound of formula VII) 36.7g, yield 83.7%, purity 98.6%.

Embodiment 2

[0046] 6-[[(4R,5S,6S)-2-[(4-nitrobenzyloxy)carbonyl]-6-[(1R)-1-hydroxyethyl]-4-methyl-7-oxo- 1-Azabicyclo[3.2.0]hept-2-en-3-yl]thio]-6,7-dihydro-5H-pyrazolo[1,2-a][1,2,4]tri Preparation of azol-4-ium chloride (compound of formula VII)

[0047] (4R,5R,6S)-3-(Diphenoxyphosphonooxy)-6-((R)-1-hydroxyethyl)-4-methyl-7-carbonyl-1-azabicyclo [3.2.0] p-nitrobenzyl hept-2-ene-2-carboxylate (compound of formula V) 50.0g, 6-mercapto-6,7-dihydro-5H-pyrazolo[1,2-a ][1,2,4]Triazol-4-ium chloride (compound of formula VI) 19.2g, N,N-dimethylformamide 23.7g and triethylamine 11.7g were added to 400g of acetonitrile, stirred, nitrogen gas Protected, stirred at -10 to -15°C for 10 hours, filtered, and dried to give 6-[[(4R,5S,6S)-2-[(4-nitrobenzyloxy)carbonyl]-6-[(1R)- 1-Hydroxyethyl]-4-methyl-7-oxo-1-azabicyclo[3.2.0]hept-2-en-3-yl]thio]-6,7-dihydro-5H-pyridine Azolo[1,2-a][1,2,4]triazol-4-ium chloride (compound of formula VII) 39.1g, yield 89.1%, purity 99.0%.

Embodiment 3

[0049] 6-[[(4R,5S,6S)-2-[(4-nitrobenzyloxy)carbonyl]-6-[(1R)-1-hydroxyethyl]-4-methyl-7-oxo- 1-Azabicyclo[3.2.0]hept-2-en-3-yl]thio]-6,7-dihydro-5H-pyrazolo[1,2-a][1,2,4]tri Preparation of azol-4-ium chloride (compound of formula VII)

[0050] (4R,5R,6S)-3-(Diphenoxyphosphonooxy)-6-((R)-1-hydroxyethyl)-4-methyl-7-carbonyl-1-azabicyclo [3.2.0] p-nitrobenzyl hept-2-ene-2-carboxylate (compound of formula V) 400.0g, 6-mercapto-6,7-dihydro-5H-pyrazolo[1,2-a Add 154.8g of [1,2,4]triazol-4-ium chloride (compound of formula VI), 129.6g of N,N-dimethylformamide and 93.6g of triethylamine into 3200g of acetonitrile, stir, and blow nitrogen Protected, stirred at -10 to -15°C for 8 hours, filtered, and dried to obtain 6-[[(4R,5S,6S)-2-[(4-nitrobenzyloxy)carbonyl]-6-[(1R)- 1-Hydroxyethyl]-4-methyl-7-oxo-1-azabicyclo[3.2.0]hept-2-en-3-yl]thio]-6,7-dihydro-5H-pyridine Azolo[1,2-a][1,2,4]triazol-4-ium chloride (compound of formula VII) 320.3g, yield 91.2%, purity 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com