Method for preparing oxidized graphene

A technology of graphene and graphite powder, which is applied in the field of graphene oxide preparation, can solve problems such as difficult peeling into a single-layer structure, long reaction time, and small graphite layer spacing, so as to avoid waste acid discharge and treatment problems and reduce economic costs. Cost and environmental protection cost, the effect of reducing the introduction of impurity ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

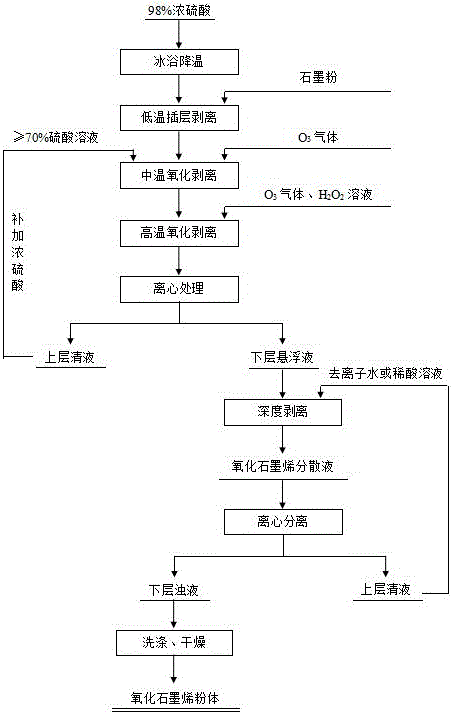

[0039] a kind of like figure 1 The preparation method of graphene oxide of the present invention shown specifically comprises the following steps:

[0040] (1) Measure 50ml of 98% concentrated sulfuric acid into a three-necked flask, and then place it in an ice-water bath to cool down to 0°C;

[0041] (2) Turn on the ultrasonic treatment, accurately weigh 2g of graphite powder (a natural flake graphite sample from a graphite factory in Chenzhou, Hunan, the chemical purity is 99.9% after mineral processing and impurity removal treatment, and the particle size is 40 mesh to 400 mesh), ultrasonic treatment At the same time, graphite powder was slowly added to the three-necked flask, and ultrasonic treatment was added under stirring conditions, and the reaction was carried out for 60 minutes to carry out low-temperature intercalation and stripping;

[0042] (3) After the low-temperature intercalation stripping carried out in the above step (2) is completed, continue the ultrasoni...

Embodiment 2

[0048] a kind of like figure 1 The preparation method of graphene oxide of the present invention shown specifically comprises the following steps:

[0049] (1) Measure 80ml of 98% concentrated sulfuric acid into a three-necked flask, and then place it in an ice-water bath to cool down to -2°C;

[0050] (2) Turn on the ultrasonic treatment, accurately weigh 4g of graphite powder (a natural flake graphite sample from a graphite factory in Chenzhou, Hunan, the chemical purity is 99.92% after mineral processing and impurity removal, and the particle size is 200 mesh to 1000 mesh), ultrasonic treatment At the same time, slowly add graphite powder into the above-mentioned three-neck flask, supplemented by ultrasonic treatment under stirring conditions, and react for 30 minutes to carry out low-temperature intercalation and stripping;

[0051] (3) After the low-temperature intercalation stripping carried out in the above step (2) is completed, continue the ultrasonic treatment and s...

Embodiment 3

[0057] a kind of like figure 1 The preparation method of graphene oxide of the present invention shown specifically comprises the following steps:

[0058] (1) Measure 100ml of 98% concentrated sulfuric acid into a three-necked flask, and then place it in an ice-water bath to cool down to 2°C;

[0059] (2) Turn on the ultrasonic treatment, accurately weigh 5g graphite powder (a natural flake graphite sample from a graphite company in Changsha, Hunan, the chemical purity is 99.9% after mineral processing and impurity removal treatment, and the particle size is 200 mesh to 600 mesh), ultrasonic treatment At the same time, graphite powder was slowly added to the above-mentioned three-necked flask, supplemented by ultrasonic treatment under stirring conditions, and reacted for 60 minutes to carry out low-temperature intercalation and stripping;

[0060] (3) After the low-temperature intercalation stripping carried out in the above step (2) is completed, continue the ultrasonic tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com