Preparation method of strontium titanate spherical nanocrystals

A nanocrystal, strontium titanate technology, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of complex preparation process, large grain size, large reaction particle size, etc., and meet the requirements of simple preparation operation. , Overcome the effect of high process complexity, large surface area and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

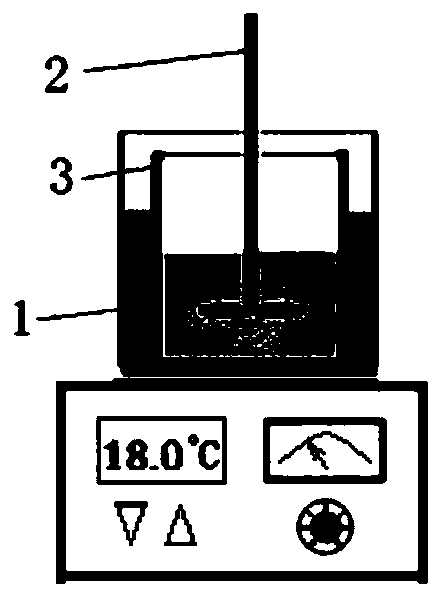

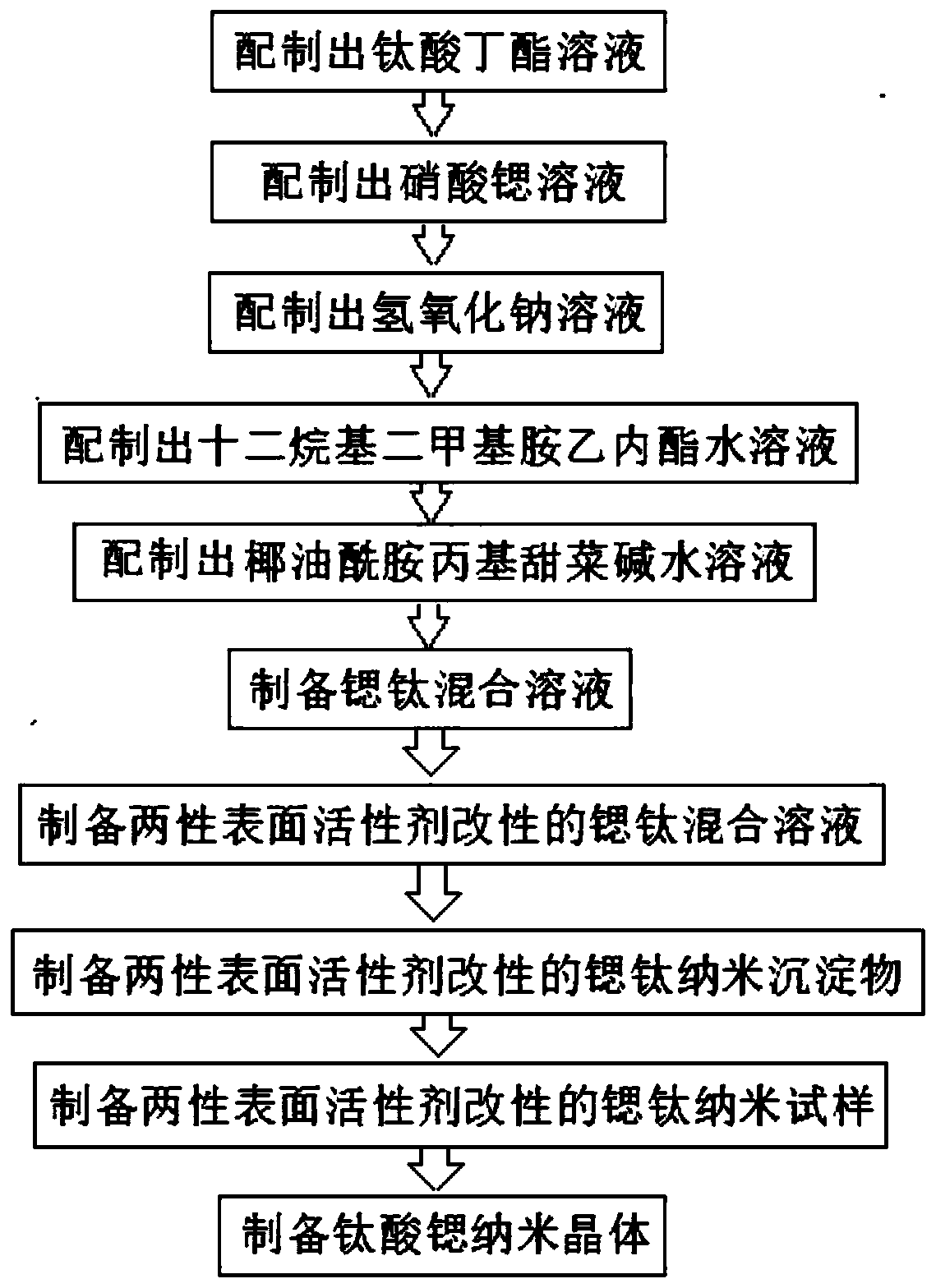

Method used

Image

Examples

Embodiment 1

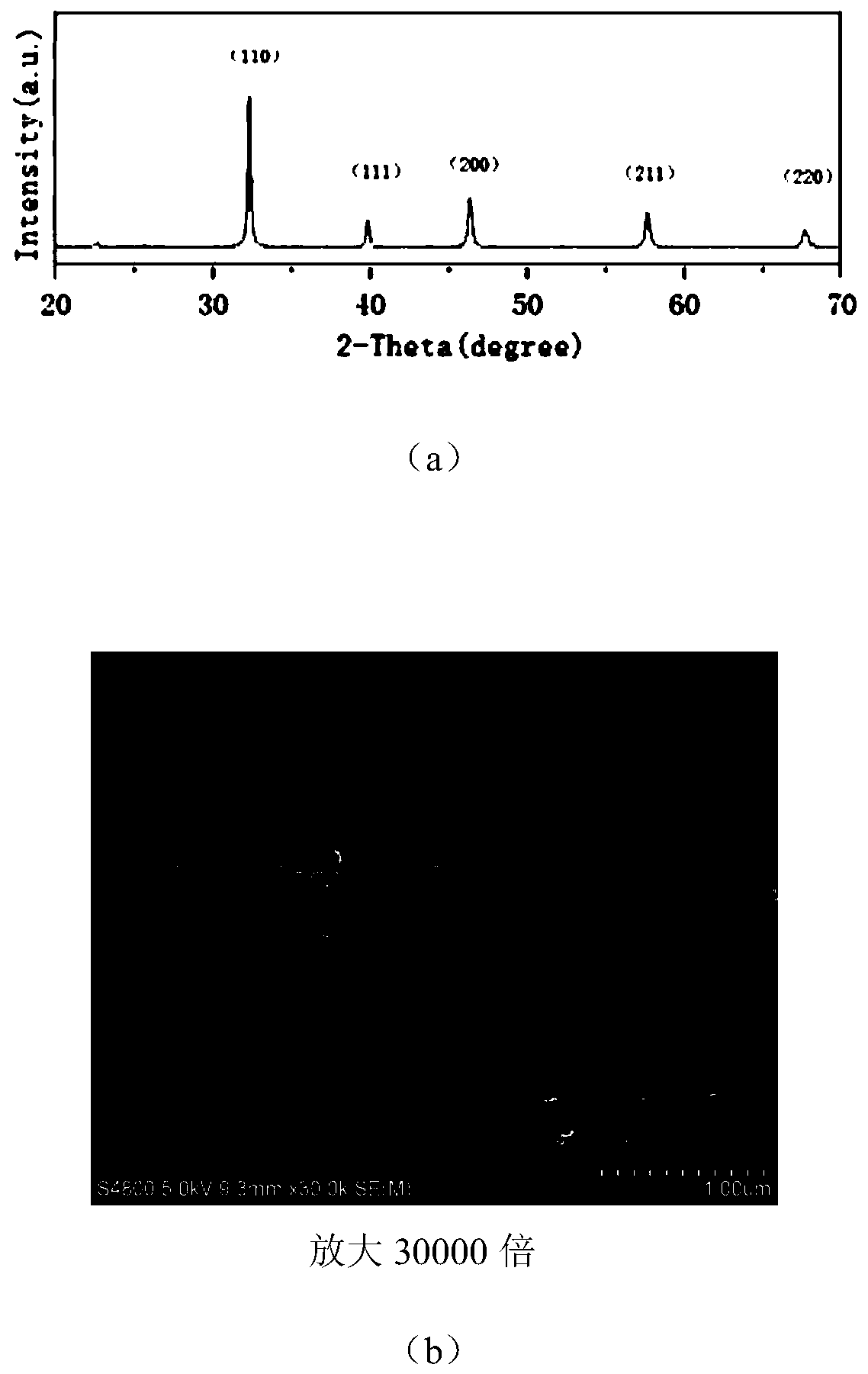

[0052] Example 1: Preparation of strontium titanate nanocrystals with a spherical shape and a diameter of 0.1 μm.

[0053] Step 1, using butyl titanate and absolute ethanol to prepare a butyl titanate solution.

[0054] The configuration process of this step is as follows:

[0055] (1a) 250mL absolute ethanol is packed into a beaker;

[0056] (1b) With a needle tube, the density is 0.966g / cm 3 , a liquid butyl titanate with a volume of 8.8 mL;

[0057] (1c) Inject the butyl titanate extracted by the needle tube obtained in (1b) into 250mL of absolute ethanol, and at the same time mix and stir with an electric mechanical stirrer at a speed of 60 rpm for 2 minutes to obtain 0.10mol / L titanium butyl ester solution.

[0058] Step 2, using strontium nitrate and deionized water to prepare a strontium nitrate solution.

[0059] The configuration process of this step is as follows:

[0060] (2a) Dissolving 7.245g of strontium nitrate into 500mL of deionized water and mixing to p...

Embodiment 2

[0092] Example 2: Preparation of strontium titanate nanocrystals with a spherical shape and a diameter of 0.4 μm.

[0093] Step 1, using butyl titanate and absolute ethanol to prepare a butyl titanate solution.

[0094] First put 250mL of absolute ethanol into a beaker; then, use a needle to extract 3 , liquid butyl titanate with a volume of 30.8mL; after that, inject the butyl titanate extracted by the needle into 250mL of absolute ethanol, and at the same time mix and stir with an electric mechanical stirrer at a speed of 60 rpm for 2 minutes to obtain 0.35mol / L butyl titanate solution.

[0095] Step 2, using strontium nitrate and deionized water to prepare a strontium nitrate solution.

[0096] First, dissolve 17.45g of strontium nitrate into 500mL of deionized water and mix to prepare a strontium nitrate aqueous solution with a concentration of 0.165mol / L; then, place the funnel on the instrument support, put a clean beaker under the funnel, and place the filter paper F...

Embodiment 3

[0113] Example 3: Preparation of strontium titanate nanocrystals with a spherical shape and a diameter of 0.5 μm.

[0114] Step A, using butyl titanate and absolute ethanol to prepare a butyl titanate solution.

[0115] (A1) 250mL absolute ethanol is packed into a beaker;

[0116] (A2) With a needle tube, the density is 0.966g / cm 3 , a liquid butyl titanate with a volume of 42.3 mL;

[0117] (A3) Inject the butyl titanate extracted by the needle obtained in (A2) into 250 mL of absolute ethanol, and at the same time mix and stir for 2 minutes with an electric mechanical stirrer at a speed of 60 rpm to obtain 0.48 mol / L of titanium butyl ester solution.

[0118] Step B, using strontium nitrate and deionized water to prepare a strontium nitrate solution.

[0119] (B1) Dissolving 31.395g of strontium nitrate into 500mL of deionized water and mixing to prepare an aqueous strontium nitrate solution with a concentration of 0.297mol / L;

[0120] (B2) Put the funnel on the instrume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com