PU sponge with good air permeability and making method thereof

A breathable and sponge technology, applied in the field of sponge foaming, can solve the problems of reduced resilience, reduced sponge density and quality, and achieved the effect of enhancing foaming function, improving quality and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

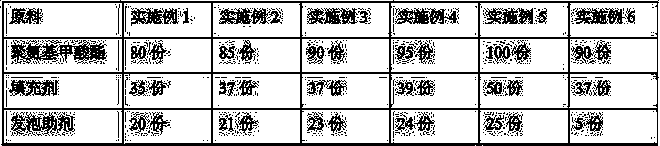

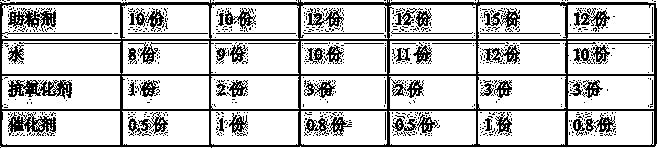

Embodiment 1

[0023] This embodiment provides a kind of PU sponge with good air permeability, and its raw material includes the following components by weight: 80 parts of polyurethane, 35 parts of filler, 20 parts of foaming aid, 10 parts of adhesion promoter, water 8 parts, 1 part of antioxidant, 0.5 part of catalyst; wherein, the filler is a mixture of titanium dioxide, calcium carbonate and talcum powder in a weight ratio of 8:3:1, and the foaming aid is a weight ratio of 1 : 1:3:0.5 foaming agent, a mixture of benzotriazole, sodium borohydride and p-octylphenol; the adhesion promoter is nitrile rubber with a weight ratio of 8:3:2, polyether A mixture of alcohol and epoxy resin, the antioxidant is a mixture of benzophenone and butyl hydroxyanisole in a weight ratio of 1:1; the catalyst is an amine catalyst.

[0024] Present embodiment also provides a kind of method for making the PU sponge with good air permeability, comprising the following steps:

[0025] Step 1, take each raw materi...

Embodiment 2

[0028] This embodiment provides a kind of PU sponge with good air permeability, and its raw material includes the following components by weight: 85 parts of polyurethane, 37 parts of filler, 21 parts of foaming aid, 10 parts of adhesion promoter, water 9 parts, 2 parts of antioxidant, 1 part of catalyst; wherein, the filler is a mixture of calcium carbonate, silicon oxide powder and talcum powder with a weight ratio of 3:1:2, and the foaming aid is a weight ratio of 1:2:2:1 foaming agent, a mixture of benzotriazole, sodium borohydride and p-octylphenol; the adhesion promoter is nitrile rubber and polyether with a weight ratio of 8:3:3 The mixture of polyol and epoxy resin, the antioxidant is hindered phenolic antioxidant; the catalyst is an amine catalyst.

[0029] Present embodiment also provides a kind of method for making the PU sponge with good air permeability, comprising the following steps:

[0030] Step 1, take each raw material according to weight part, set aside; ...

Embodiment 3

[0033]This embodiment provides a kind of PU sponge with good air permeability, and its raw material includes the following components by weight: 90 parts of polyurethane, 37 parts of filler, 23 parts of foaming aid, 12 parts of adhesion promoter, water 10 parts, 3 parts of antioxidant, 0.8 part of catalyst; Wherein, described filler is the mixture of calcium carbonate, silica powder and talcum powder that weight ratio is 7:3:2, and described foaming aid is the weight ratio of 3:2:4:1.5 foaming agent, a mixture of benzotriazole, sodium borohydride and p-octylphenol; the adhesion promoter is nitrile rubber and polyether with a weight ratio of 10:5:2 The mixture of polyol and epoxy resin, the antioxidant is xanthone, ethoxyquinoline, hindered phenolic antioxidant, benzophenone, phenylenedioctyl, butylated A mixture of hydroxyanisole; the catalyst is an amine catalyst.

[0034] Present embodiment also provides a kind of method for making the PU sponge with good air permeability, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com