Prepn of foamed aluminium

A foamed aluminum and foam material technology, applied in the electrolysis process, electroforming, etc., can solve the problems of slow diffusion of aluminum ions, etc., and achieve the effect of small pore size, high porosity, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

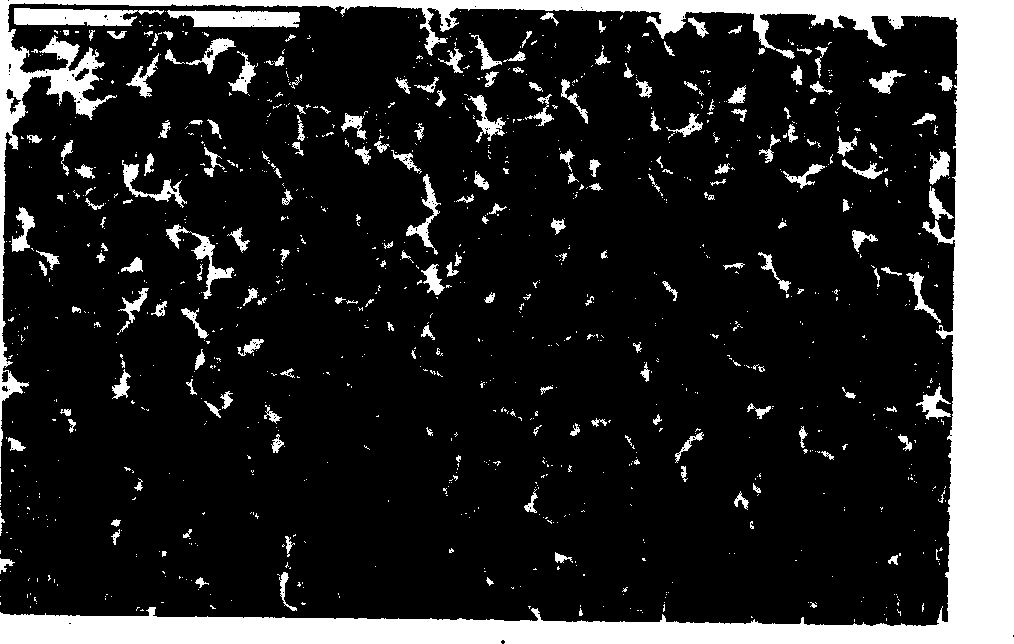

Embodiment approach 1

[0036] Polyurethane foam is selected as the base material, with an average pore size of 0.60mm and a porosity of 90%. After degreasing, degreasing, and stress removal, it is ionized and placed in an electroless copper plating solution to electrolessly plate a layer of copper conductive surface layer. The thickness of the conductive surface layer is 3 to 5 μm. The polyurethane foam material treated by this method is used as the cathode and placed in the electroplating tank of anhydrous organic alkyl aluminum electrolyte, and the industrial pure aluminum plate is used as the anode. aluminum electrodeposition. The electroplating tank of the anhydrous organic alkyl aluminum electrolyte contains 150 parts of triethylaluminum, 20 parts of NaF, and 220 parts of toluene; the temperature of the plating solution is controlled at 80-90° C.; the electrodeposition time is 1 hour.

[0037] The plating cell may be a conventional Watts plating cell. The electroplating power supply is a puls...

Embodiment approach 2

[0043] Polyethylene foam is selected as the base material, with an average pore diameter of 0.85mm and a porosity of 92%. After degreasing, degreasing, and stress removal, it is ionized and placed in an electroless nickel plating solution to electrolessly plate a layer of nickel conductive surface layer. The thickness of the conductive surface layer is 0.1-3 μm. The polyethylene foam material treated by this method is used as the cathode and placed in the electroplating tank of the anhydrous organic alkyl aluminum electrolyte, and the industrial pure aluminum plate is used as the anode, and the aluminum is electrodeposited by the pulse electroplating method. The electroplating tank of the anhydrous organic alkyl aluminum electrolyte contains 225 parts of triethylaluminum, 50 parts of KF, 160 parts of toluene and ethylbenzene, 4, 4`diamino-3,3`dimethyloxydiphenyl 5 parts of methane; the temperature of the plating solution is controlled at 60-80°C; the electrodeposition time is...

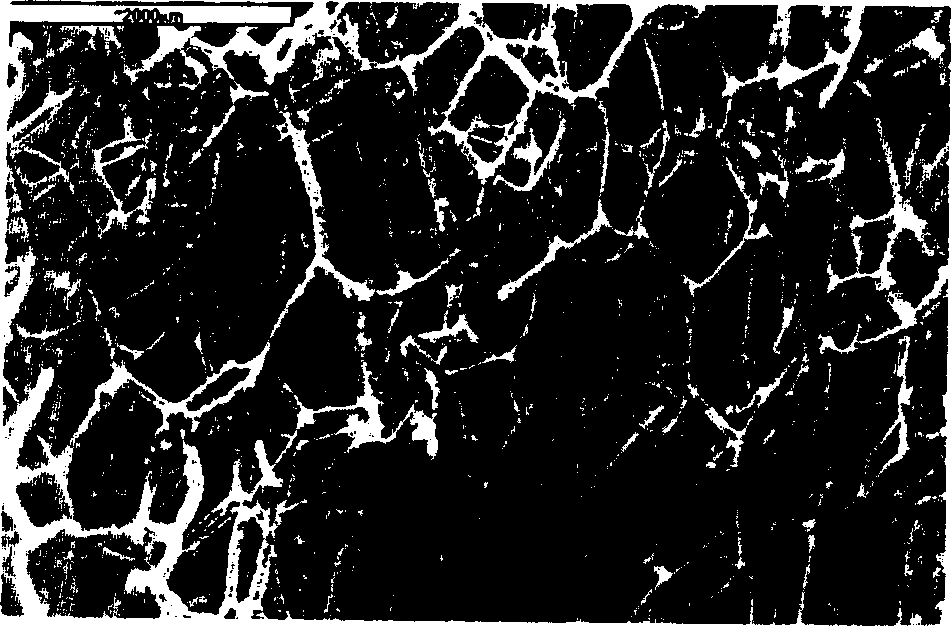

Embodiment 3

[0048] Polypropylene foam is selected as the base material, with an average pore diameter of 3.40mm and a porosity of 96%. Pretreatment with the method of coating conductive adhesive. The polypropylene foam material after this conductive treatment is used as the cathode and placed in the electroplating tank of the anhydrous organic alkyl aluminum electrolyte, and the industrial pure aluminum plate is used as the anode, and the aluminum is electrodeposited by the pulse electroplating method. The electroplating tank of the anhydrous organic alkyl aluminum electrolyte contains 300 parts of triethylaluminum, 40 parts of NaF, 20 parts of CaF, 3 parts of 4,4`diamino-3,3`dimethyloxydiphenylmethane, 420 parts of ethylbenzene; the temperature of the plating solution is controlled at 50-80°C; the electrodeposition time is 2 hours.

[0049] The electroplating tank uses a traditional Watt electroplating tank. The electroplating power supply is a pulsed DC power supply. The current wave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com