Lithium ion battery negative electrode active material, lithium ion battery negative electrode, lithium ion battery, battery pack and battery power vehicle

A lithium-ion battery, negative electrode technology, applied in battery electrodes, batteries, secondary batteries, etc., can solve problems such as reduced discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

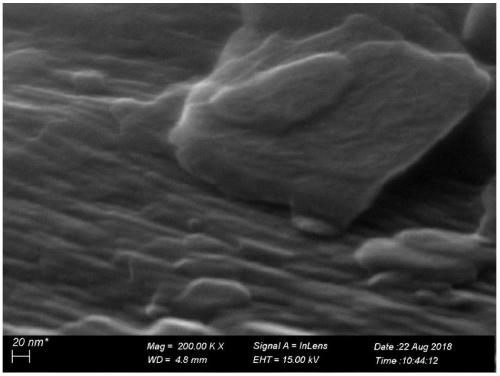

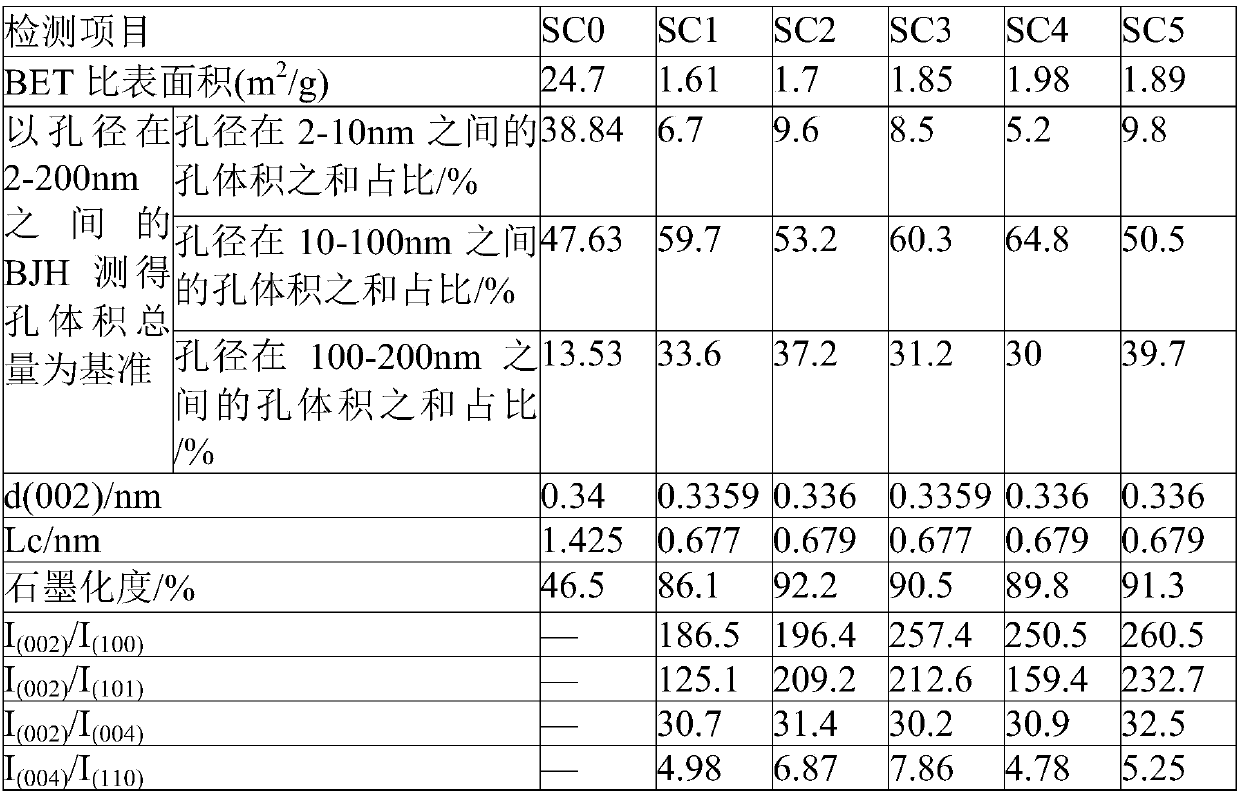

[0075] 1. Preparation of lithium-ion battery negative electrode carbon particles:

[0076] In the present invention, casting coke is selected as the carbon source (SCO), and the casting coke is dried until the water content is lower than 1% by weight. The carbon source was crushed until the D50 was 10-18 μm, and the carbon source was purified with 30 volume % HF. The carbon source and the HF solution were mixed uniformly at a volume ratio of 1:1.2, and stirred for 30 minutes to form a mixture. After the mixture is separated, the solid is rinsed with deionized water, and after separation, the separated solid is dried for use.

[0077] The dried solid is subjected to carbonization treatment, and the whole carbonization treatment process includes three heating stages. The first heating stage is: heating from room temperature to 500°C at a heating rate of 3°C / min, and keeping the temperature at 500°C for 30 minutes; the second heating stage is: heating to 1000°C at a heating rate...

Embodiment 2

[0089] According to the method of embodiment 1, its difference is:

[0090] When preparing lithium-ion battery negative electrode carbon particles, the dried solids are subjected to carbonization treatment, and the entire carbonization treatment process includes six heating stages. The first heating stage is: heating from room temperature to 200°C at a heating rate of 4°C / min, and keeping the temperature constant for 30 minutes; the second heating stage is: heating to 500°C at a heating rate of 5°C / min, and keeping the temperature constant for 30 minutes; The third heating stage is: heating to 800°C at a heating rate of 5°C / min, and keeping the temperature constant for 20 minutes; the fourth heating stage is: heating to 1000°C at a heating rate of 4°C / min, and keeping the temperature constant for 20 minutes; the fifth heating stage is: The temperature was raised to 1200°C at a heating rate of 4°C / min, and the temperature was kept constant for 20 minutes; the sixth heating stag...

Embodiment 3

[0094] According to the method of embodiment 1, its difference is:

[0095] The dried solid is subjected to carbonization treatment, and the whole carbonization treatment process includes three heating stages. The first heating stage is: heating from room temperature to 500°C at a heating rate of 3°C / min, and keeping the temperature at 500°C for 20 minutes; the second heating stage is: continuing to heat at a heating rate of 3°C / min to 1000°C , and keep the temperature at 1000°C for 30min; the third heating stage is: continue heating to 1500°C at a heating rate of 3°C / min, and keep the temperature at 1500°C for 30min.

[0096] The carbonized solid is subjected to graphitization treatment, and the entire graphitization treatment process includes three heating stages. The first heating stage is: heating to 1350°C at a heating rate of r1=3°C / min, and keeping the temperature at 1350°C for 30 minutes; the second heating stage is: heating to 1980 at a heating rate of r2=2.8°C / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com