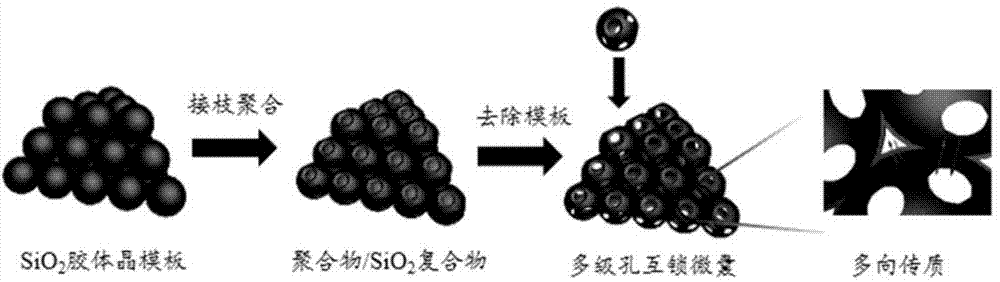

Preparation method of interlocking micro-capsules based on polymer with high specific surface area and having hierarchical porous structure

A technology with high specific surface area and polymer, which can be used in the preparation of microspheres, microcapsules, etc., and can solve the problems of shrinkage, high price, and complicated preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

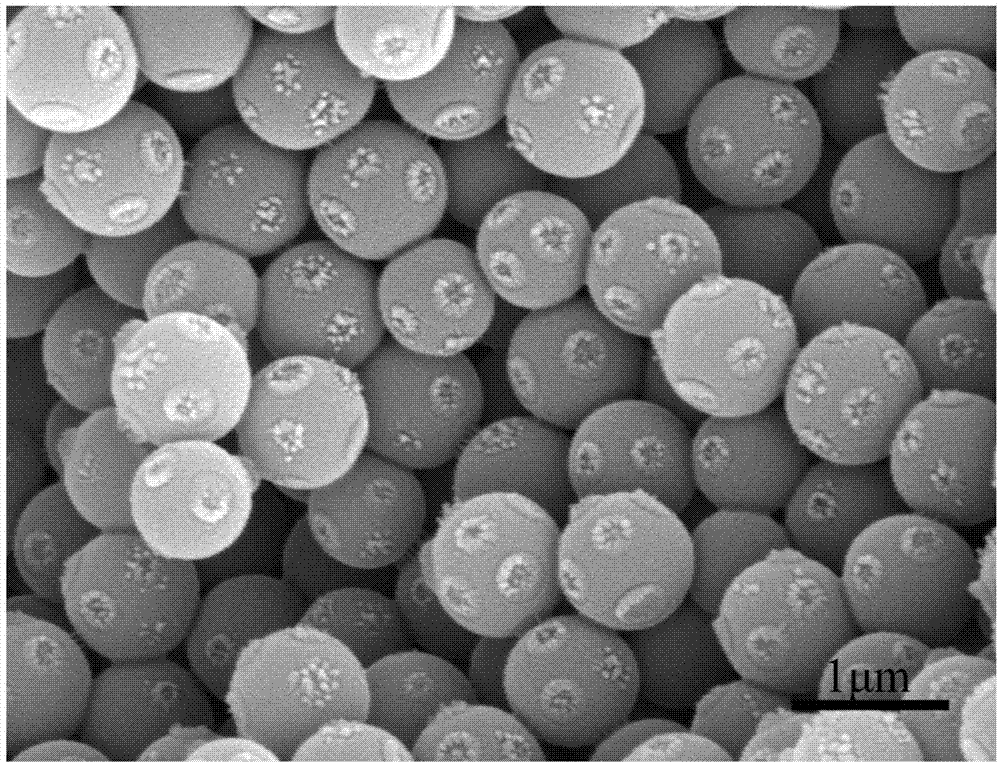

[0063] (1) Preparation of 600nm silica colloidal crystal template

[0064] Add 145g of absolute ethanol, 34.1g of ammonia water with a mass fraction of 25%, and 35.0g of deionized water to a 500mL three-necked bottle equipped with mechanical stirring at room temperature. After stirring evenly, quickly add 15.4g of orthosilicon Acid ethyl ester, reacted at room temperature for 8h. Transfer the obtained suspension into a beaker, wait for the solvent to volatilize completely naturally, and obtain a colloidal silica template with an average particle size of 600nm, and finally sinter the template in a muffle furnace at 500°C for 3 hours, and slowly lower it to room temperature to obtain A silica colloidal crystal template in which silica microspheres with an average particle size of 600nm are adhered to each other;

[0065] (2) Surface modification of silica colloidal crystal template

[0066] Silane coupling agent [3-(2-bromoisobutyryl)aminopropyl]-triethoxysilane (BITS) modifie...

example 1

[0076] The surface area measured by the material obtained in Example 1 with the model Micromeritics ASAP2020M+C full-automatic specific surface area analyzer can reach 1000m 2 g -1 .

[0077] Description: the preparation method of silane coupling agent [3-(2-bromoisobutyryl) aminopropyl]-triethoxysilane in step (2) of the present invention is as follows: (other embodiments are the same)

[0078] Add 40.0mL toluene, 16.0mL (3-aminopropyl)triethoxysilane (APTS), 9.40mL triethylamine (TEA) into a 250mL three-necked flask, stir in an ice-water bath, and dissolve 8.40mL 2-bromoiso Dissolve butyryl bromide in 40mL of toluene, add the mixture dropwise into a three-necked flask, drop it for 1 hour, stir in an ice bath for 3 hours, then stir at room temperature for 10 hours to obtain a solid-liquid mixture, filter the mixture, and remove the filtrate by distillation under reduced pressure The unreacted TEA and solvent toluene can be used to obtain the surface modifier BITS, and the s...

Embodiment 2

[0080] (1) The preparation of 600nm silica colloidal crystal template is the same as the first step of embodiment;

[0081] (2) Surface modification of silica colloidal crystal template

[0082] γ-methacryloyloxypropyltrimethoxysilane (MPS) modified silica colloidal crystal template, put 0.3g of dried and sintered silica colloidal crystal template into a 250mL three-necked bottle, add 100ml of ethanol , distilled water 2.5mL, ammonia water 0.25mL, stirred mechanically at 25°C, added γ-methacryloxypropyltrimethoxysilane (MPS) 1.5mL, condensed and refluxed at room temperature for 24h. Stop stirring after the reaction, discard the liquid, wash and replace with absolute ethanol three times, and finally vacuum-dry at 25°C for 12 hours to obtain an MPS-modified silica colloidal crystal template with an average particle size of 600nm;

[0083] (3) Silica colloidal crystal template controllable grafting of polymer segments

[0084] Add 0.03 g of MPS-modified silica colloidal crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com