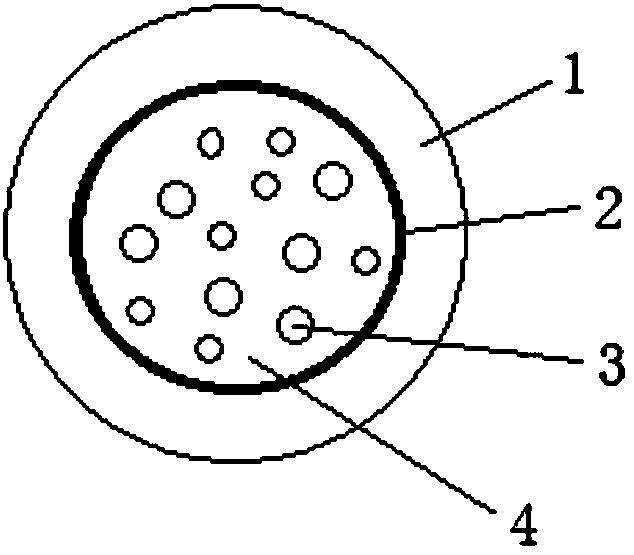

Core-shell-structured silicon carbon negative electrode material and preparation method therefor

A technology of anode material and core-shell structure, which is applied in the field of silicon-carbon anode materials with core-shell structure and its preparation, can solve the problems of reduced delithiation capacity, damage to the conductive network, and low Coulombic efficiency, and achieve stable cycle performance and inhibition Effect of volume change and improvement of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix SiO particles with a D50 of about 5 μm and NaOH at a mass ratio of 20:1, and heat at 50°C for 20 minutes in an argon protective gas to react to obtain SiO, Si, SiO 2 and nuclear materials composed of silicates;

[0031] (2) Add 0.5ml, 10wt% 3-aminopropyltriethoxysilane (APS) to the aqueous suspension of the nuclear material, heat to 40°C and continue to stir for 5h, then add a small amount of hydrochloric acid to make the solution pH 5, obtain a positively charged SiO-APS suspension.

[0032] (3) prepare the graphene quantum dot (GQDs) aqueous solution of 1.5mg / ml graphene quantum dot (GQDs) with acidification oxidation method, wherein the particle size distribution of graphene quantum dot (GQDs) is 2-10nm, and thickness is 1.6-3.2 nm;

[0033] (4) Slowly add the positively charged SiO-APS suspension in step 2) into the negatively charged graphene quantum dot (GQDs) aqueous solution, and stir for 40 min after ultrasonication. Obtain coated SiO by electrostati...

Embodiment 2

[0041] (1) Mix SiO particles with a D50 of about 5 μm and NaOH at a mass ratio of 17:1, heat at 950°C for 20 minutes in an argon protective gas, and obtain SiO, Si, and SiO by the reaction of SiO and NaOH 2 and nuclear materials composed of silicates;

[0042] (2) Add 1ml of 10wt% 3-aminopropyltriethoxysilane (APS) to the nuclear material aqueous suspension, heat to 30°C and continue to stir for 6h, then add a small amount of alkene hydrochloric acid to make the solution pH 6, An electropositive SiO-APS suspension was obtained.

[0043]Step 3) preparing an aqueous solution of carbon dots with a concentration of 3mg / ml by electrochemical method, wherein the particle size distribution of CDs is 2-10nm, and the thickness is 1.6-3.2nm;

[0044] Step 4) Slowly add the positively charged SiO-APS suspension in step 2) into the negatively charged CDs aqueous solution, and stir for 30 minutes after ultrasonication. Obtain CDs-coated SiO by electrostatic adsorption, followed by drying...

Embodiment 3

[0048] (1) Mix SiO particles with a D50 of about 5 μm and NaOH at a mass ratio of 23:1, heat at 950°C for 20 minutes in an argon protective gas, and obtain SiO, Si, and SiO by the reaction of SiO and NaOH 2 and nuclear materials composed of silicates;

[0049] (2) Add 1.5ml of 8wt% 3-aminopropyltriethoxysilane (APS) to the nuclear material aqueous suspension, heat to 50°C and continue stirring for 4h, then add a small amount of dihydrochloric acid to make the solution pH 5, An electropositive SiO-APS suspension was obtained.

[0050] Step 3) Using graphite as a raw material, prepare an aqueous solution of CDs carbon dots with a concentration of 1.5-4.5 mg / ml by an acidification oxidation method, wherein the particle size distribution of CDs is 2-10 nm, and the thickness is 1.6-3.2 nm;

[0051] Step 4) Slowly add the positively charged SiO-APS suspension in step 2) into the negatively charged CDs aqueous solution, and stir for 60 min after ultrasonication. Obtain CDs-coated S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com