Patents

Literature

33results about How to "Act as a buffer layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

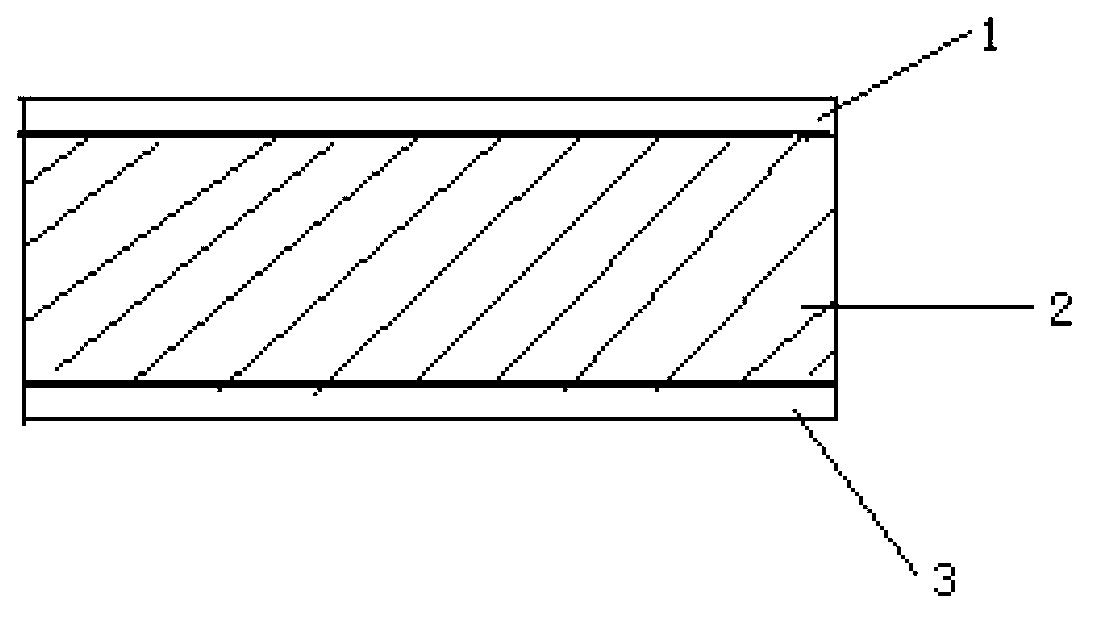

Core-shell-structured silicon carbon negative electrode material and preparation method therefor

ActiveCN107863512ASolve the disadvantages of low first-time Coulombic efficiencyInhibition of volume changeCell electrodesSecondary cellsCarbon dotCoating

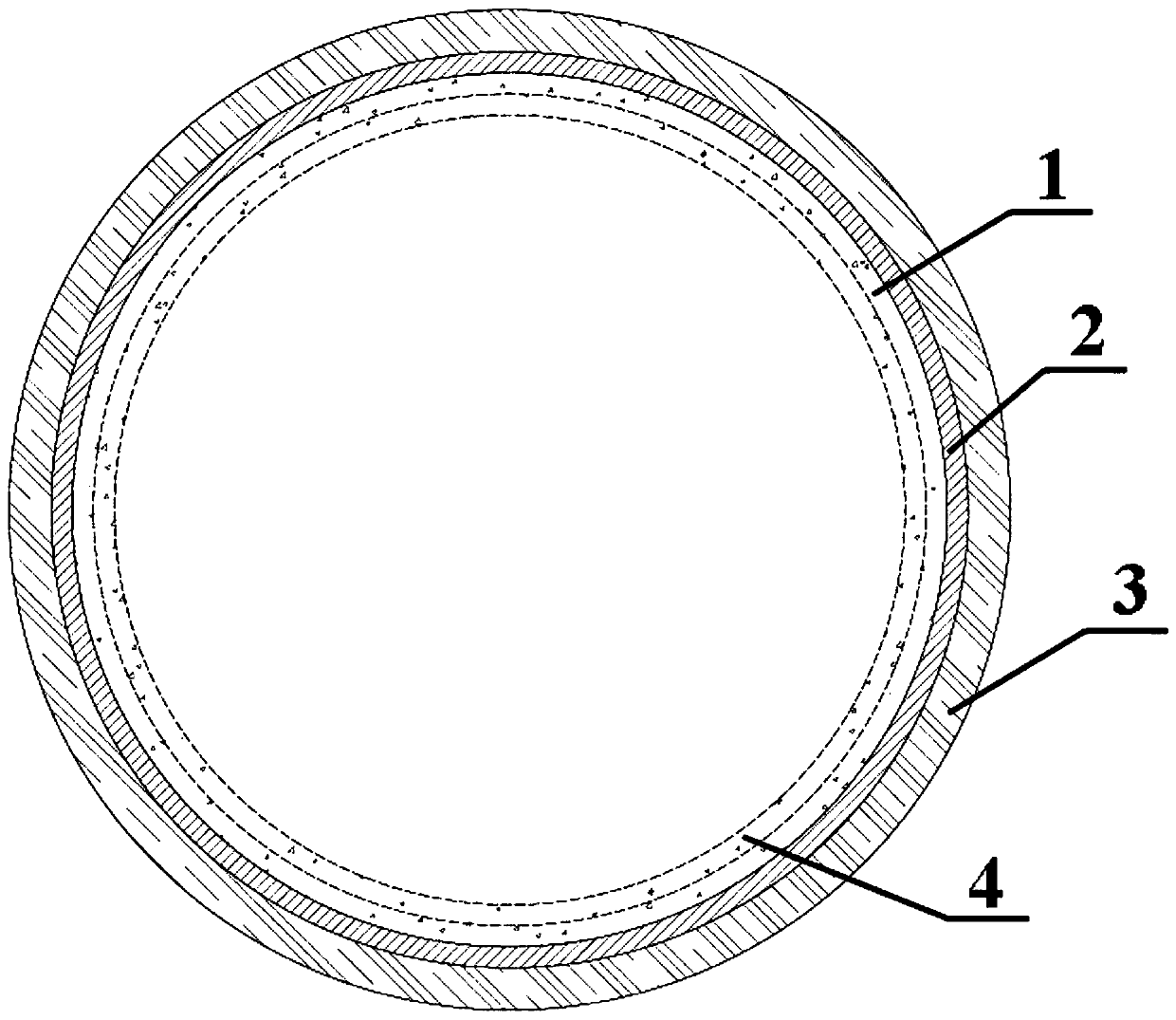

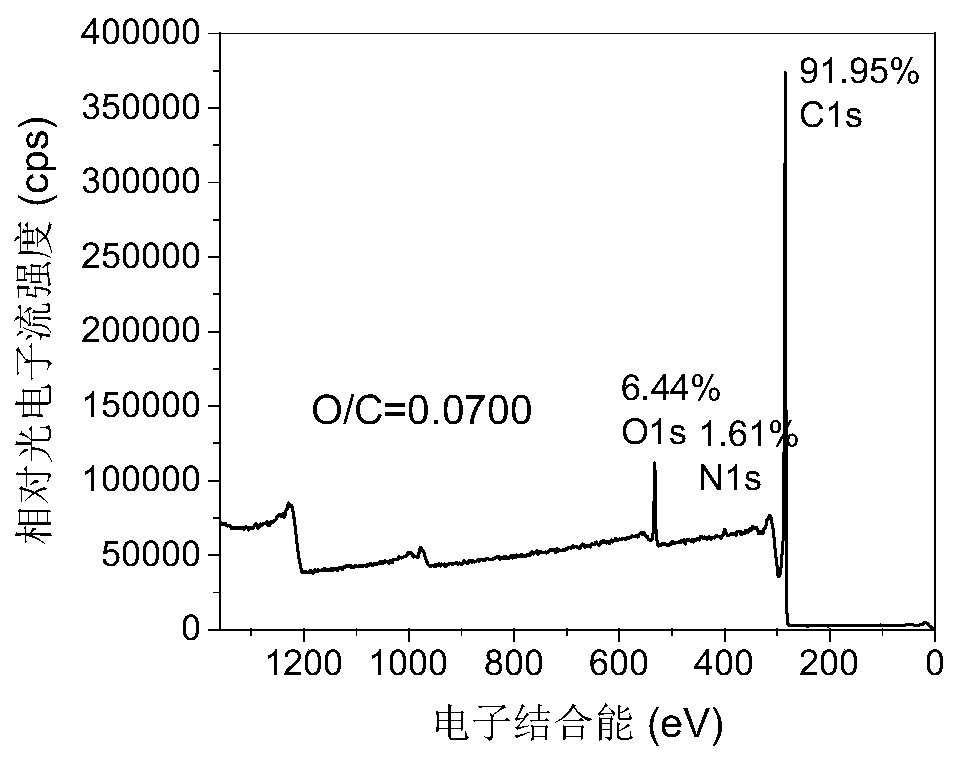

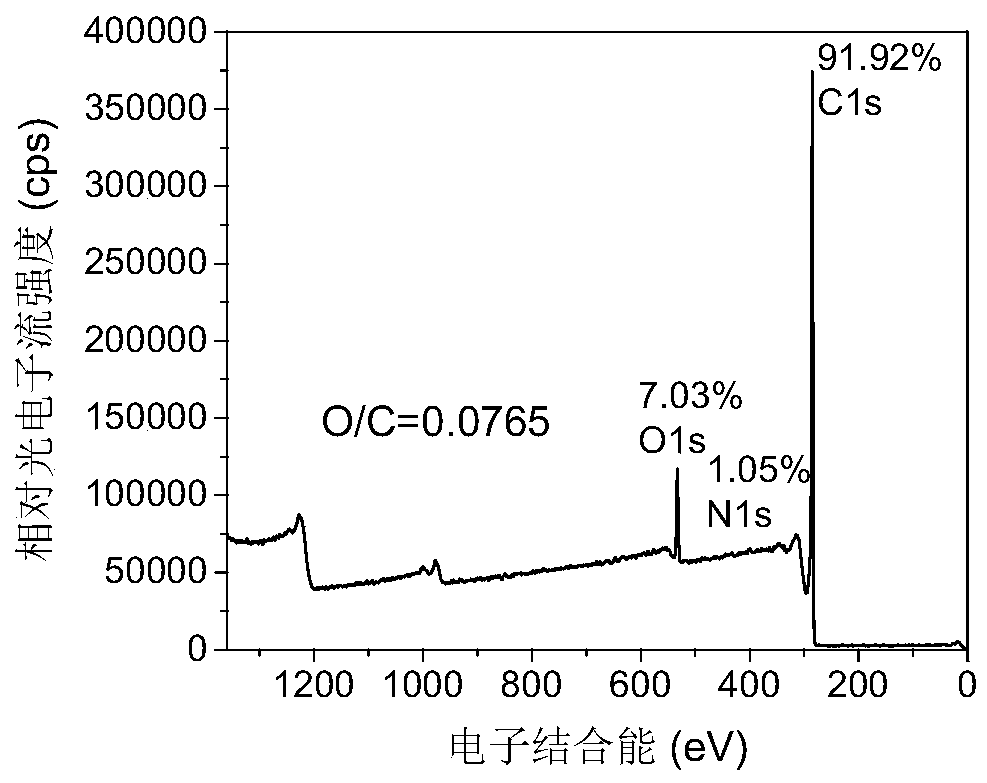

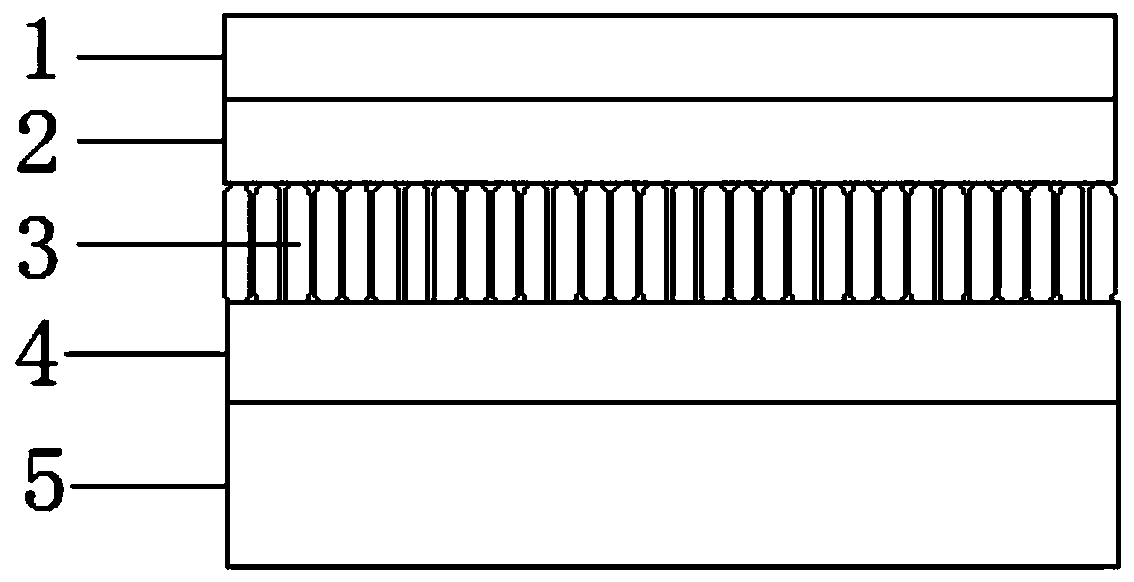

The invention discloses a core-shell-structured silicon carbon negative electrode material and a preparation method therefor. The silicon carbon negative electrode material comprise a core, a buffer layer and a shell from inside to outside in sequence; the core material consists of SiO, Si, SiO<2> and silicate; the buffer layer material comprises carbon dots or graphene quantum dots; and the shellmaterial is a hard carbon material. The core material disclosed in the invention comprises a modified SiO material; through a high-temperature reaction between SiO and NaOH, nanometer silicon and sodium silicate are generated, so that the shortcoming of low initial coulombic efficiency caused by a reaction between SiO and Li in the initial charging process can be solved; meanwhile, by taking thegenerated sodium silicate as a buffer medium, volume change of the material in the lithium de-intercalation process can be suppressed effectively, and cycle performance of the electrode can be improved; and by taking conductive carbon as a coating layer and by introducing the carbon dots or graphene quantum dots, the material conductivity is improved and a buffer effect can be played, thereby realizing stable cycle performance and high reversible capacity of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

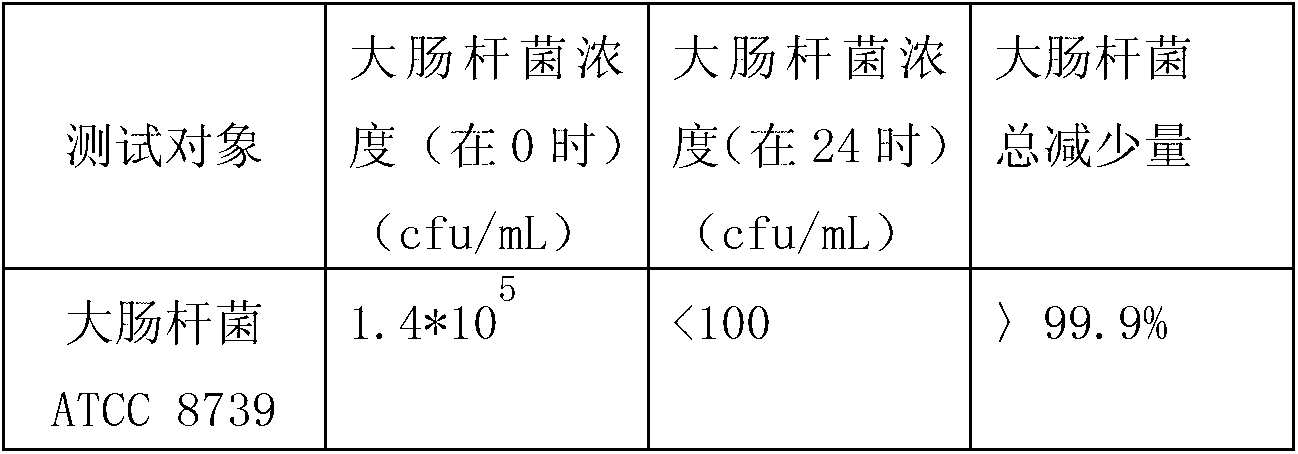

Antibacterial and odor removing fiber bed core and preparation method thereof

InactiveCN103054388AImprove bulkIncrease elasticityStuffed mattressesSpring mattressesFiberPolyester

The invention discloses an antibacterial and odor removing fiber bed core. The fiber bed core comprises at least one middle layer and a surface layer which is arranged on the upper surface or the lower surface of the middle layer, wherein the surface layer comprises a non-woven fabric prepared from the following components in percentage by weight: 15-40% of low melting point fibers and 60-85% of polyester fibers; and the middle layer comprises the following components in percentage by weight: 60-85% of raw bamboo fibers and 15-40% of low melting point fibers. The invention further discloses a preparation method of the fiber bed core; and the preparation method comprises the following steps: respectively preparing each layer including an upper surface layer, a lower surface layer and the middle layer; laying the upper surface layer, the lower surface layer and the middle layer in sequence; drying the upper surface layer, the lower surface layer and the middle layer in a drying box; and coldly rolling, cooling, cutting, inspecting and packaging the upper surface layer, the lower surface layer and the middle layer. The fiber bed core disclosed by the invention has the advantages as follows: antibacterial and odor removing properties, elasticity and bulkiness, healthcare property, ultraviolet resistance, moisture absorbing and removing properties and environment friendliness of the fiber bed core are greatly improved when being compared with those of a traditional mattress.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

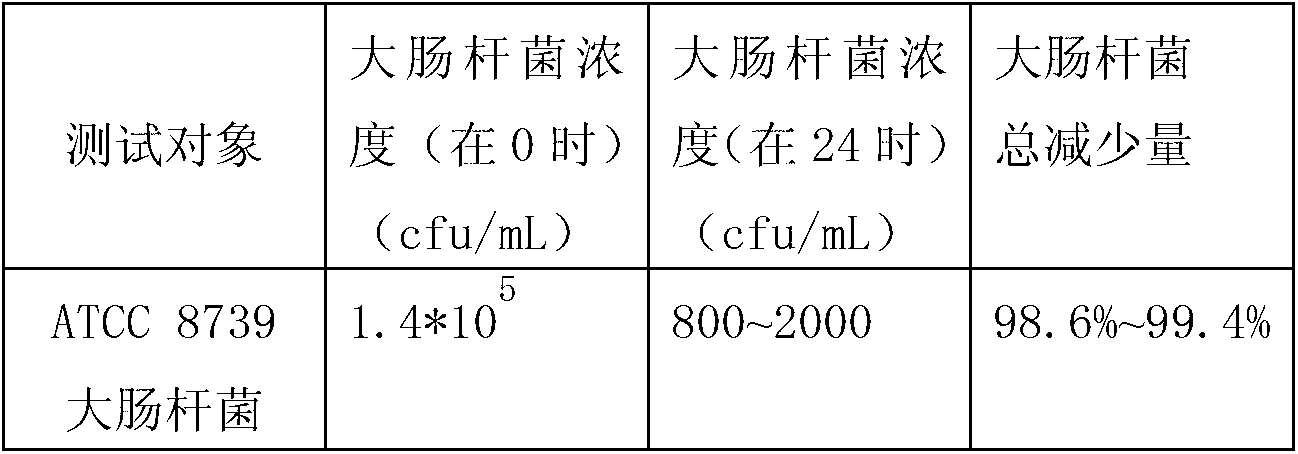

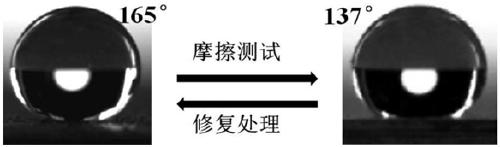

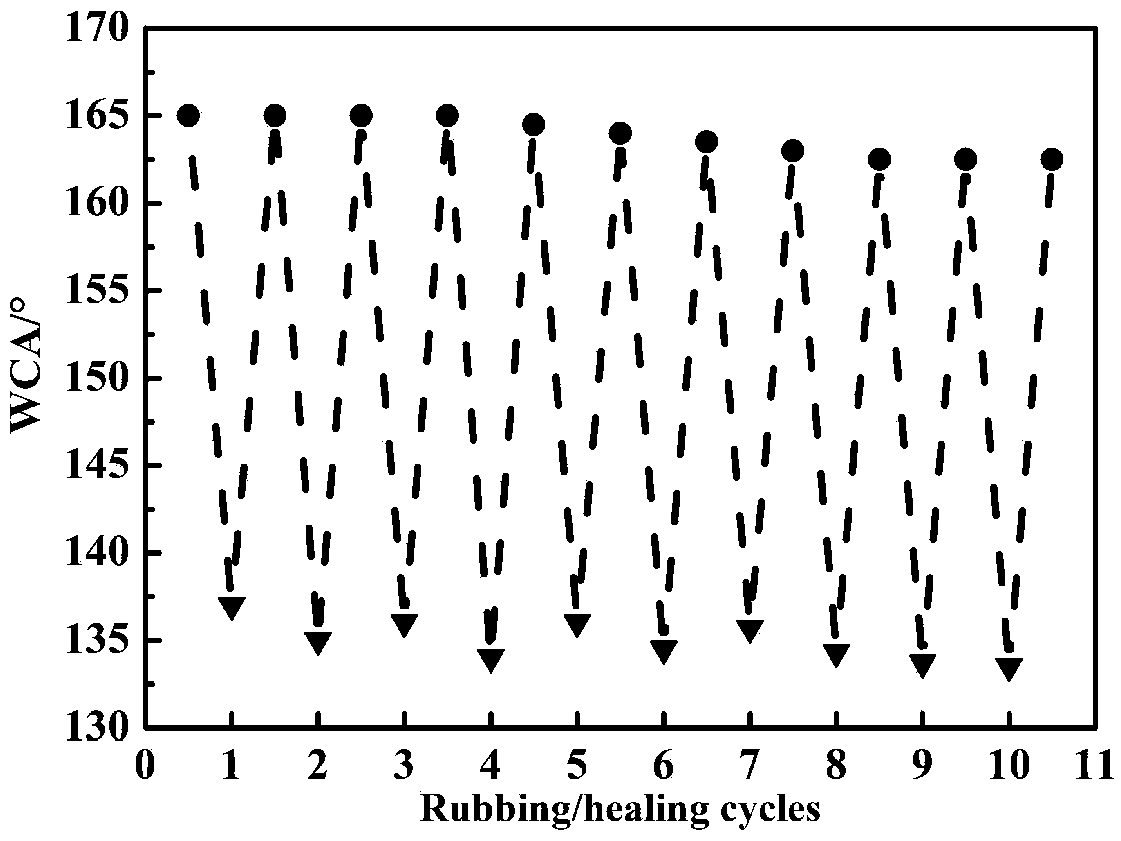

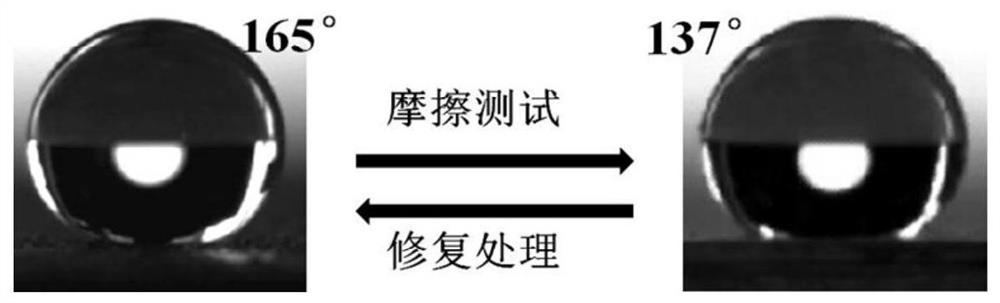

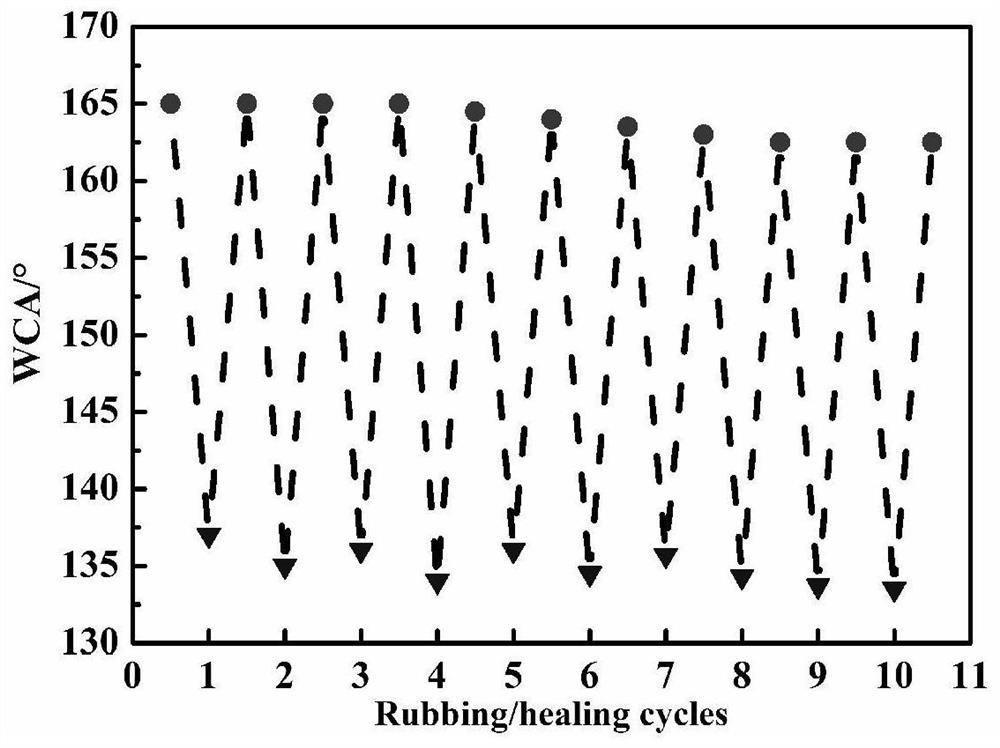

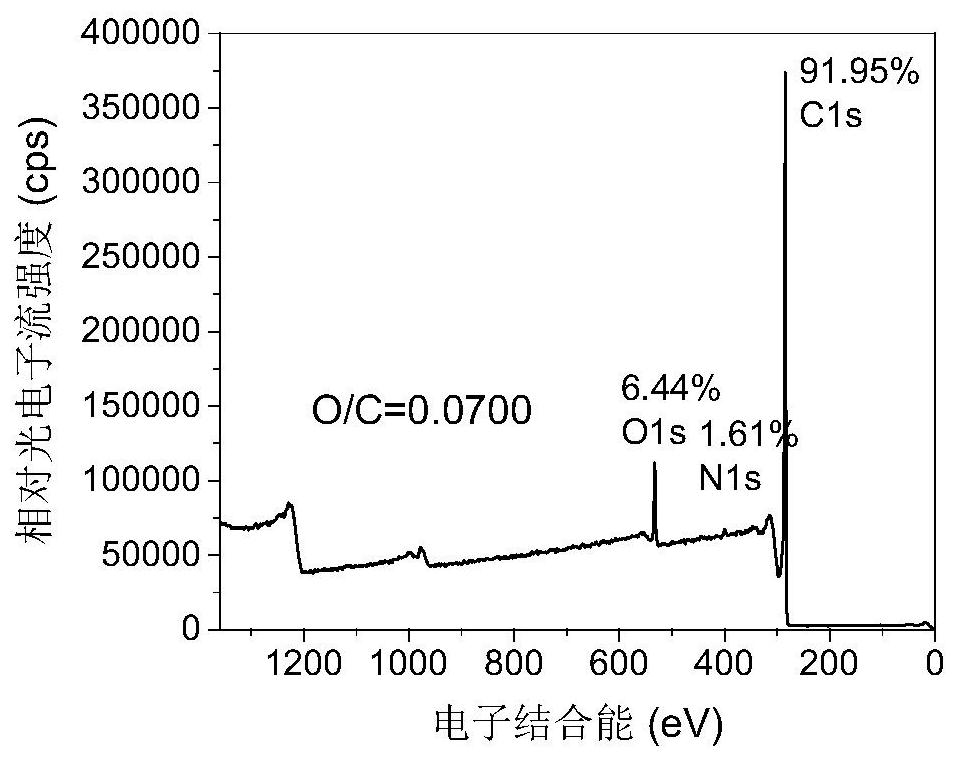

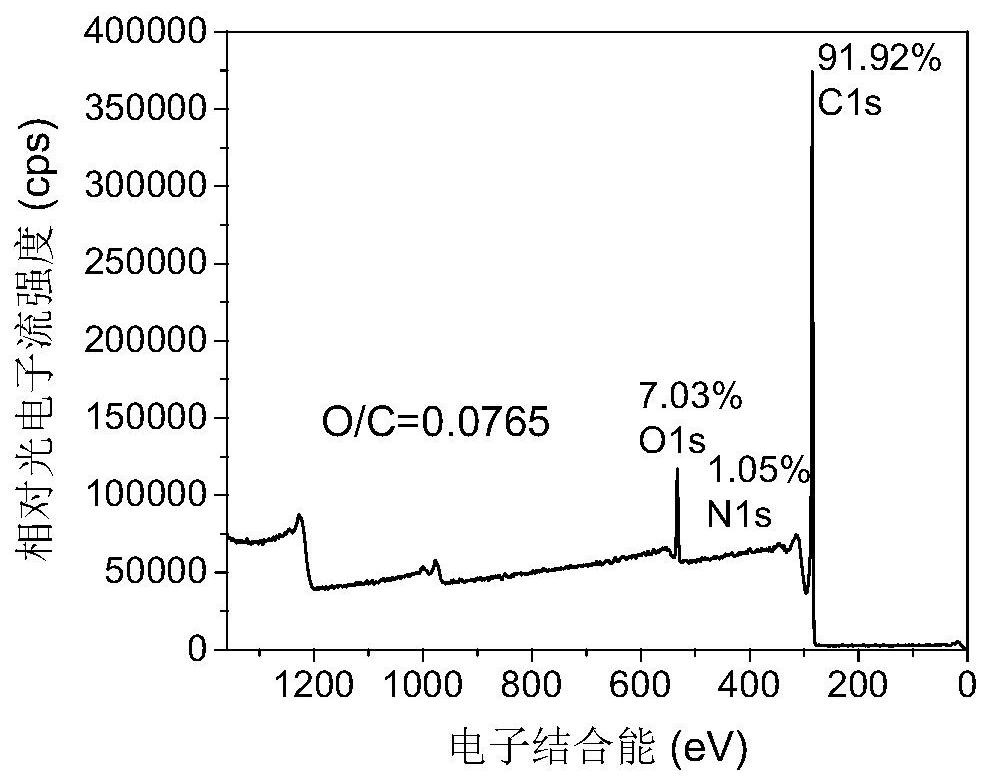

Superhydrophobic powder coating and preparation method thereof

ActiveCN109651920AImprove stabilityHas surface chemical composition repair functionAnti-corrosive paintsPowdery paintsChemical compositionSuperhydrophobic coating

The invention discloses a superhydrophobic powder coating. The superhydrophobic powder coating comprises a functional filler, and the functional filler comprises porous particles, a low surface energysubstance and vulcanized silicone rubber. A preparation method of the superhydrophobic powder coating comprises the following steps: the low surface energy substance is adsorbed in the pores of the porous particles to obtain modified porous particles; and the surface of the vulcanized silicone rubber is wrapped with the modified porous particles to obtain the functional filler. A problem that thesuperhydrophobic durability of the surface of an existing superhydrophobic coating layer is only enhanced by a single repairing chemical composition substance is solved; and the microstructure and the chemical composition materials of the damaged surface of the superhydrophobic coating layer are simultaneously repaired in the method, so the hydrophobic durability of the surface of the coating layer is effectively improved.

Owner:NORTHEAST GASOLINEEUM UNIV

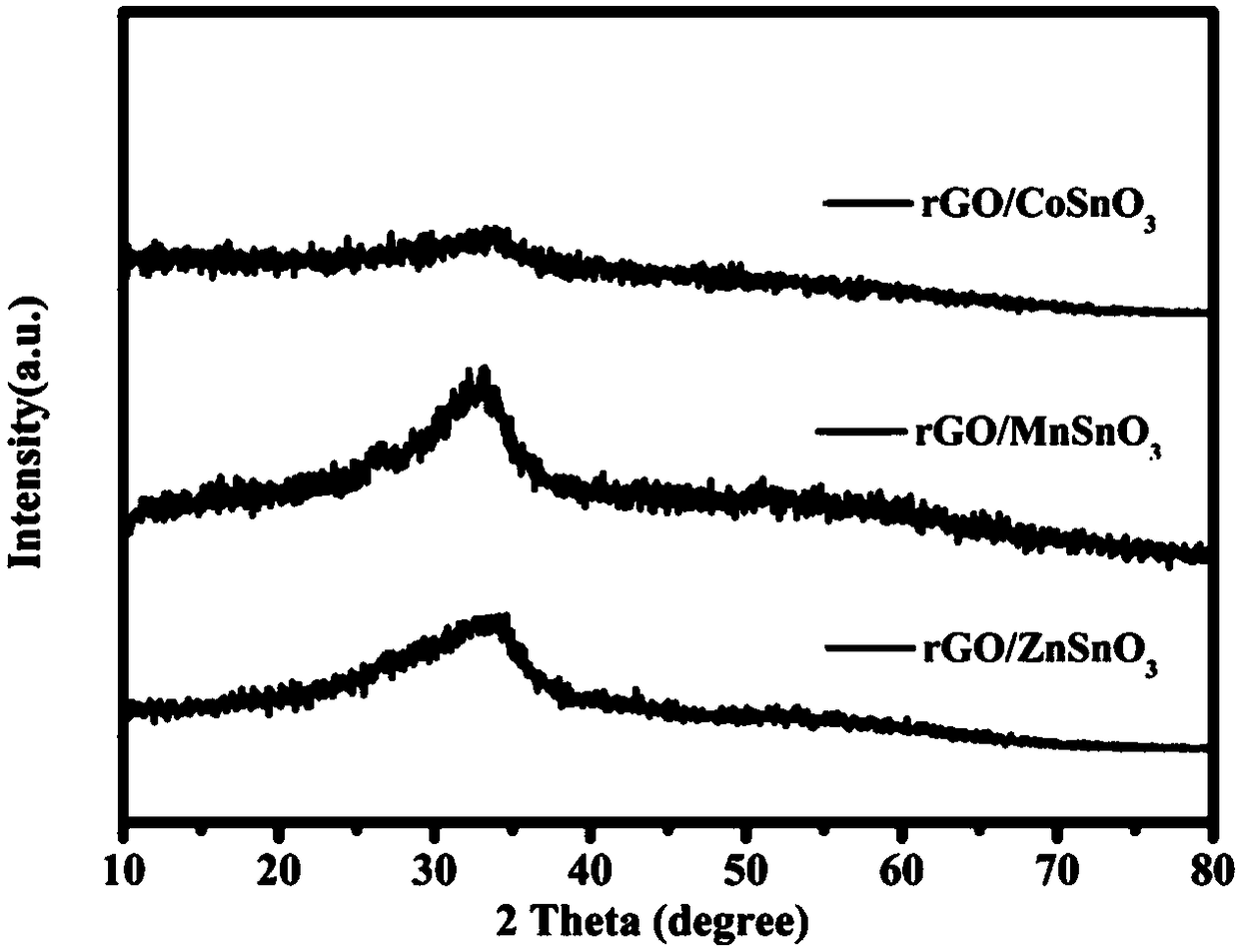

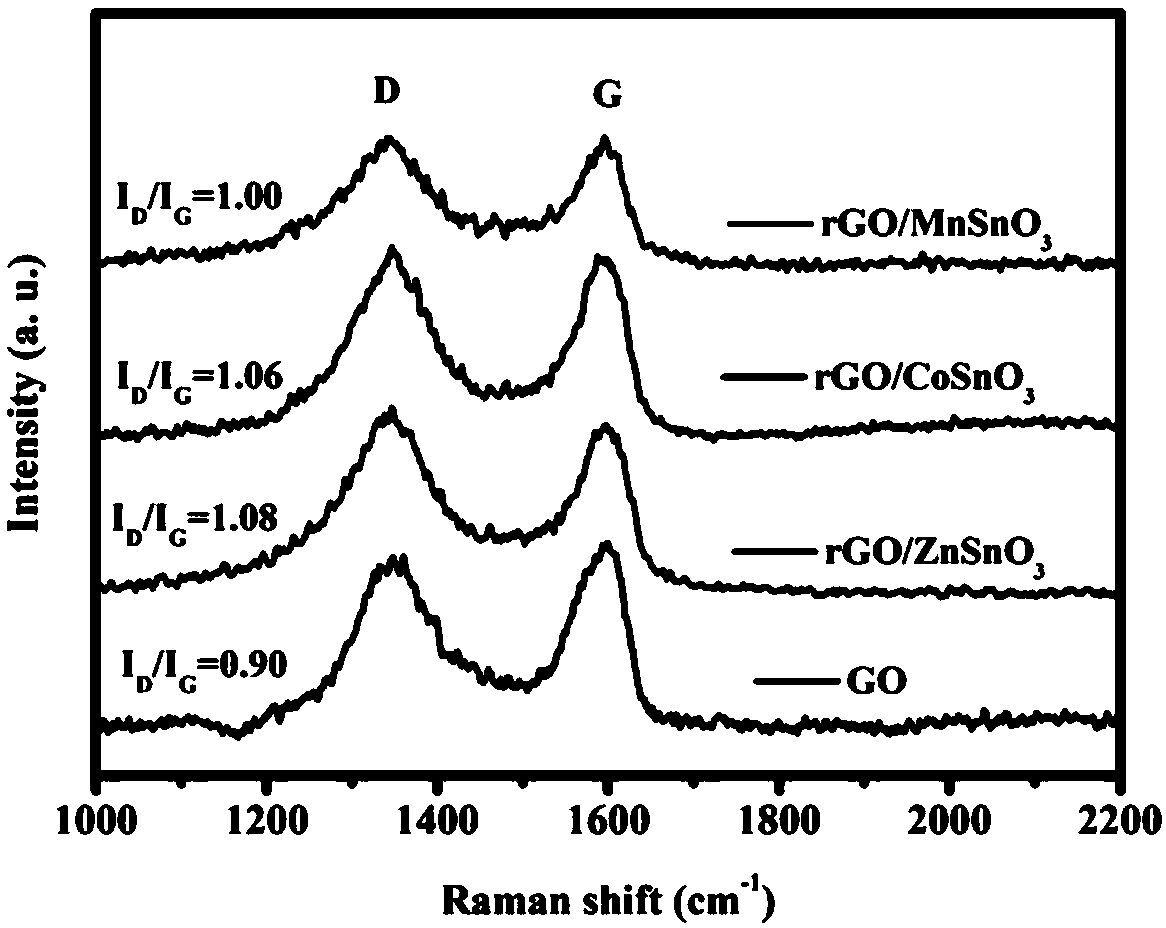

Reduced graphene oxide/stannate sodium ion battery negative electrode material and preparation method and application thereof

InactiveCN108807945AFacilitated DiffusionReduce polarizabilityMaterial nanotechnologyCell electrodesSodium-ion batteryStannate

The invention relates to a reduced graphene oxide / stannate sodium ion battery negative electrode material and a preparation method and application thereof. The preparation method comprises the following steps: dispersing an aqueous solution of chlorate and sodium stannate in a graphene oxide solution, performing a hydrothermal reaction to produce a suspension, performing solid-liquid separation toobtain a precipitate, and calcinating the precipitate at high temperature to obtain the reduced graphene oxide / stannate sodium ion battery negative electrode material, wherein the chlorate is manganese chloride, cobalt chloride hexahydrate or zinc chloride. Compared with the prior art, the preparation method provided by the invention has the advantages of a simple technology, easy process control, easy obtainment of raw materials, low cost and good repeatability. A prepared reduced graphene oxide / stannate (manganese stannate, cobalt stannate and zinc stannate) composite structure has good electrochemical sodium storage performance, and is a good sodium ion battery negative electrode material.

Owner:SHANGHAI UNIV OF ENG SCI

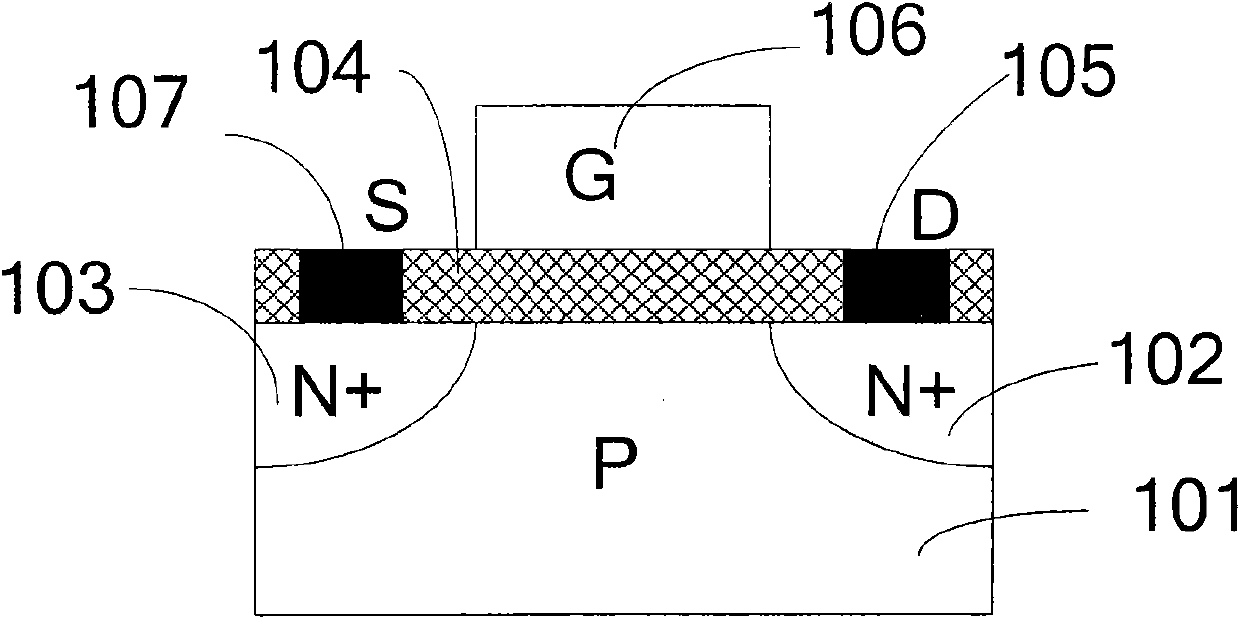

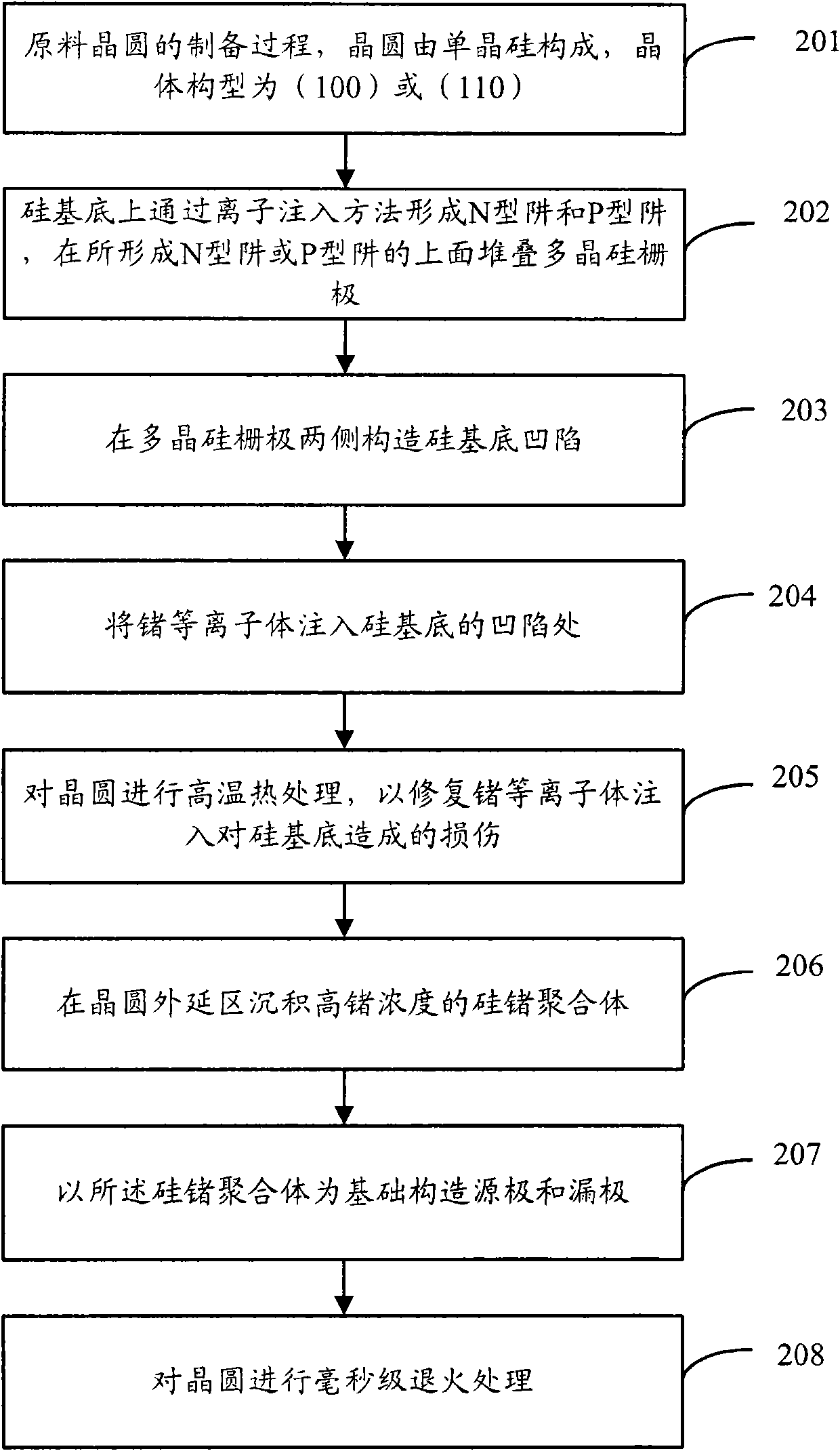

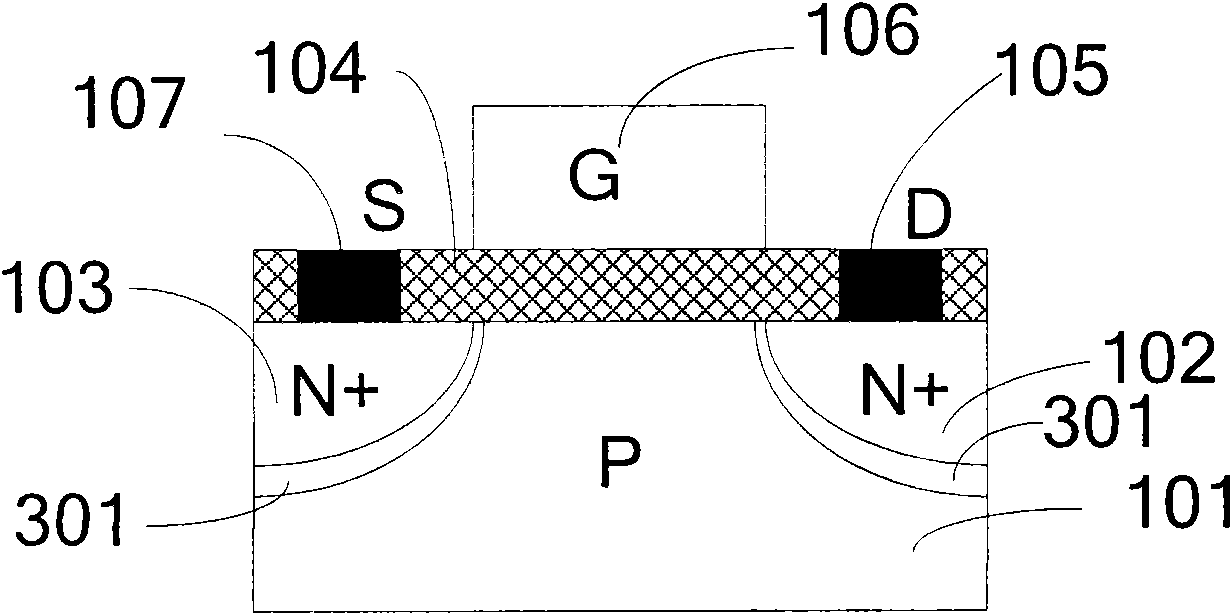

Metal oxide semiconductor field effect transistor and manufacturing method thereof

InactiveCN102024849APrevent stress relaxationAct as a buffer layerTransistorSemiconductor/solid-state device manufacturingMOSFETStress relaxation

The invention discloses a metal oxide semiconductor field effect transistor (MOSFET), comprising a silicon substrate and a source and a drain which are formed by doped silicon-germanium polymers, wherein buffer layers formed by injection of germanium plasmas are respectively arranged between the silicon substrate and the source as well as between the silicon substrate and the drain. The invention also discloses a manufacturing method of the MOSFET. The invention can effectively avoid the defects caused by stress relaxation of the silicon-germanium polymer layers.

Owner:SEMICON MFG INT (SHANGHAI) CORP

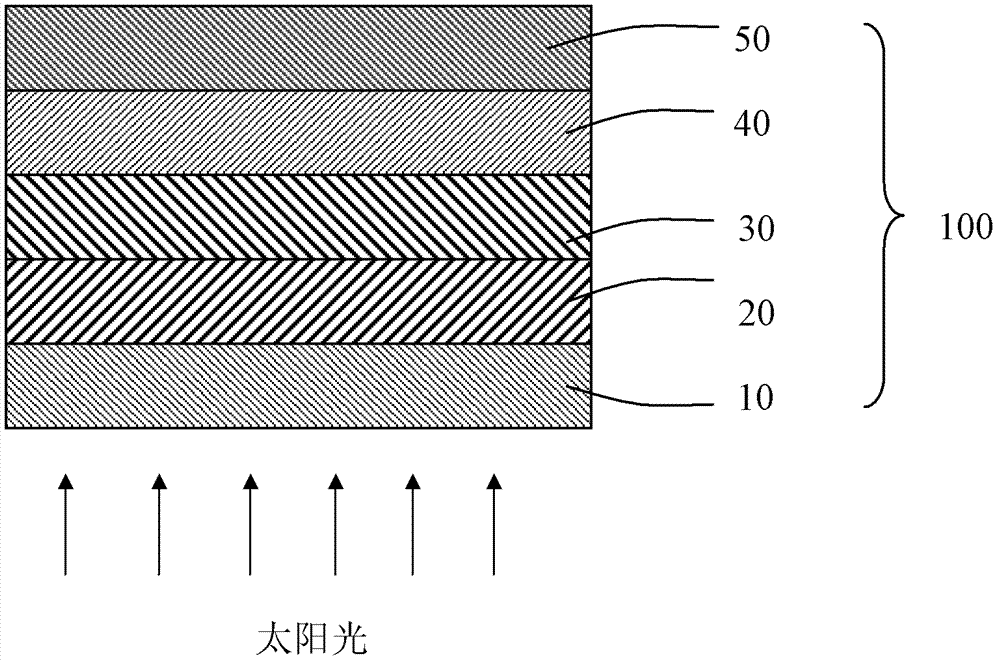

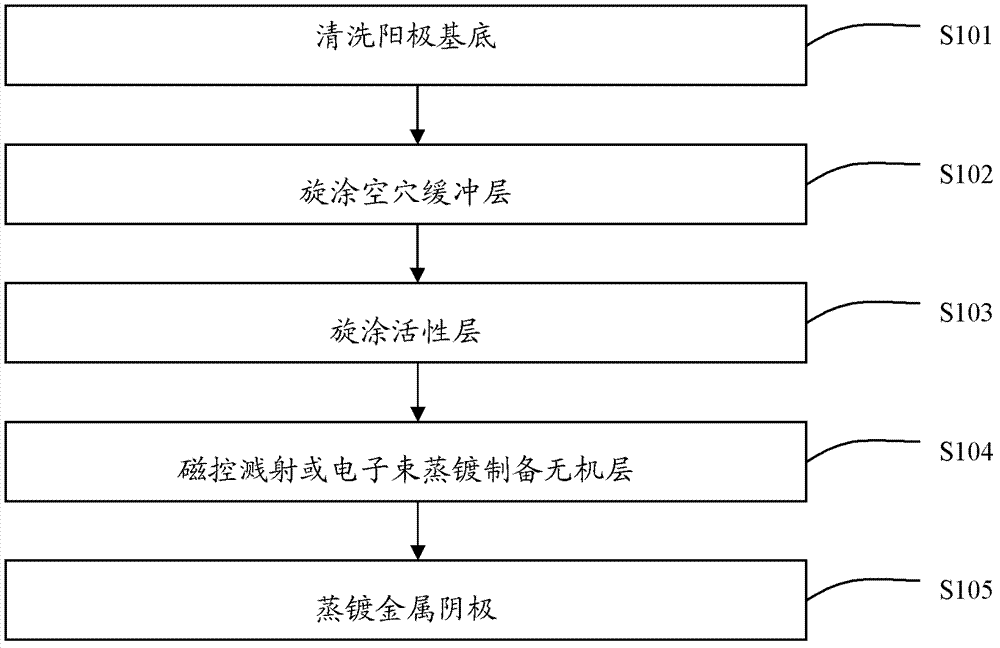

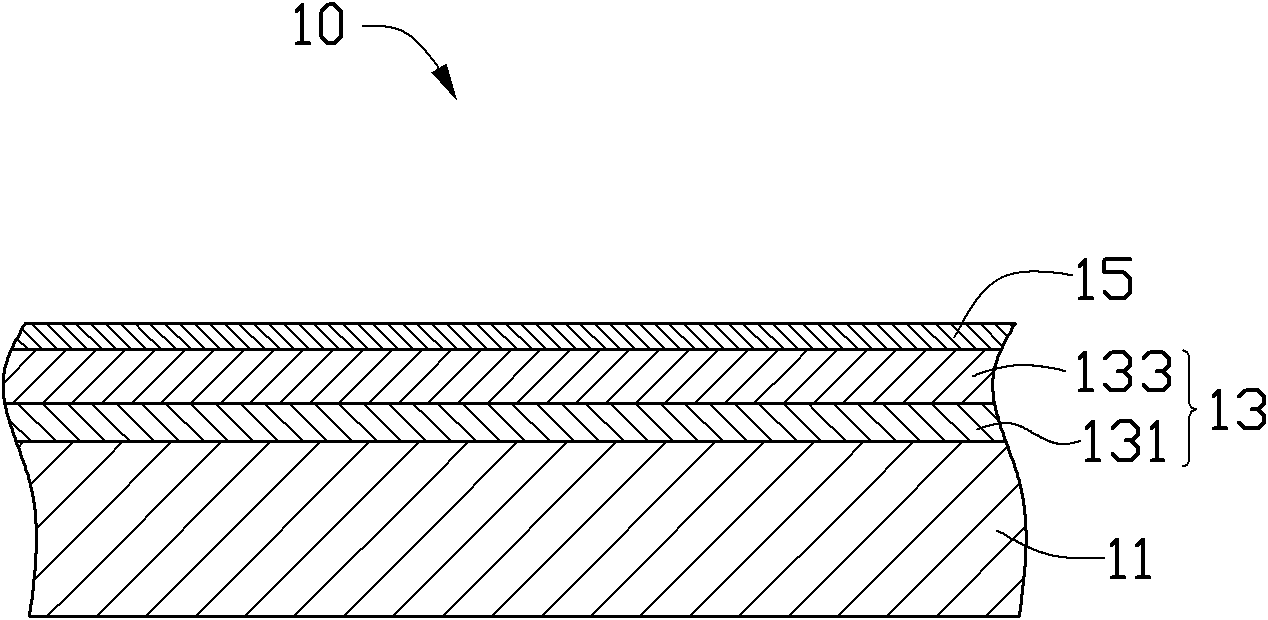

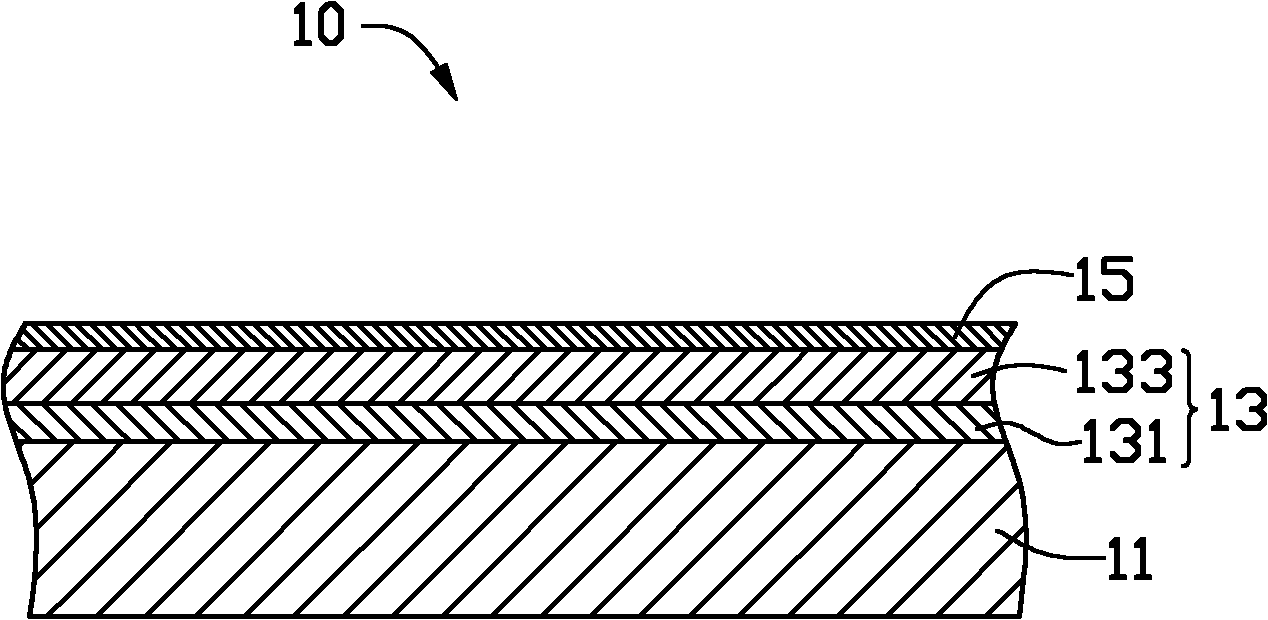

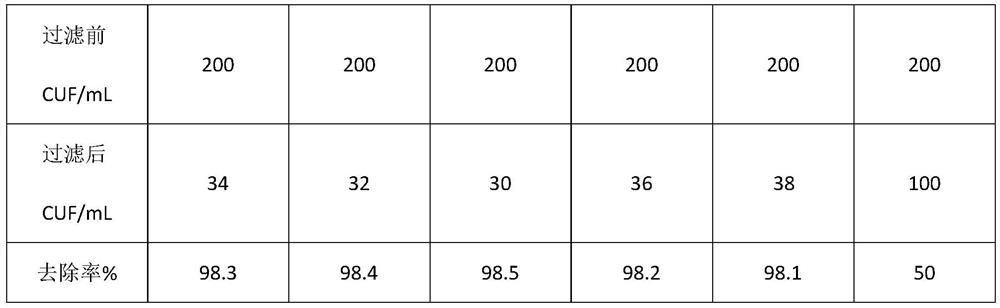

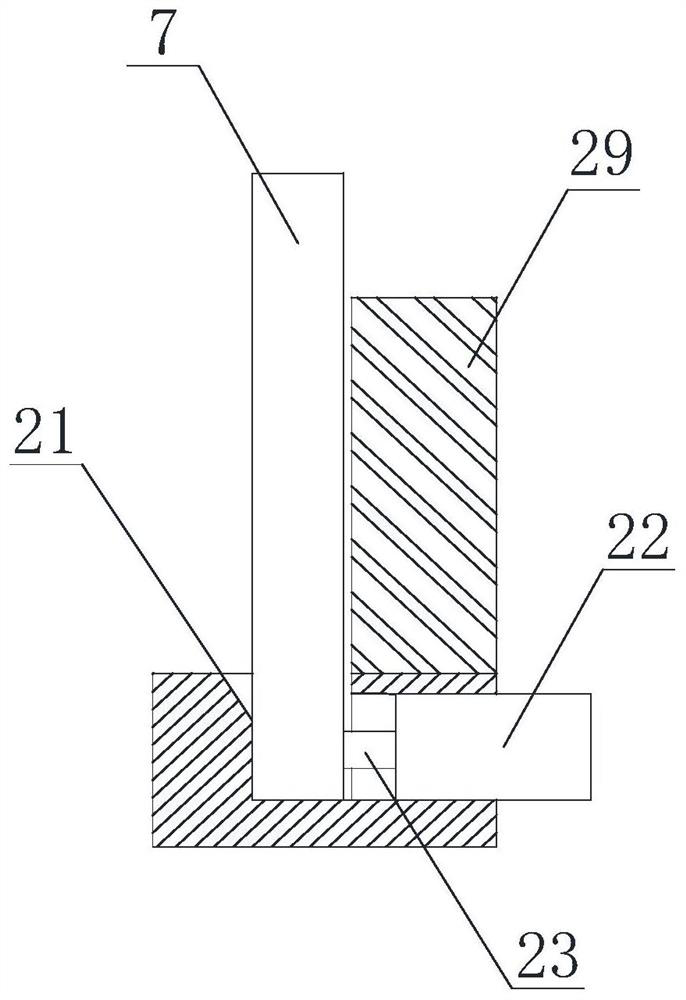

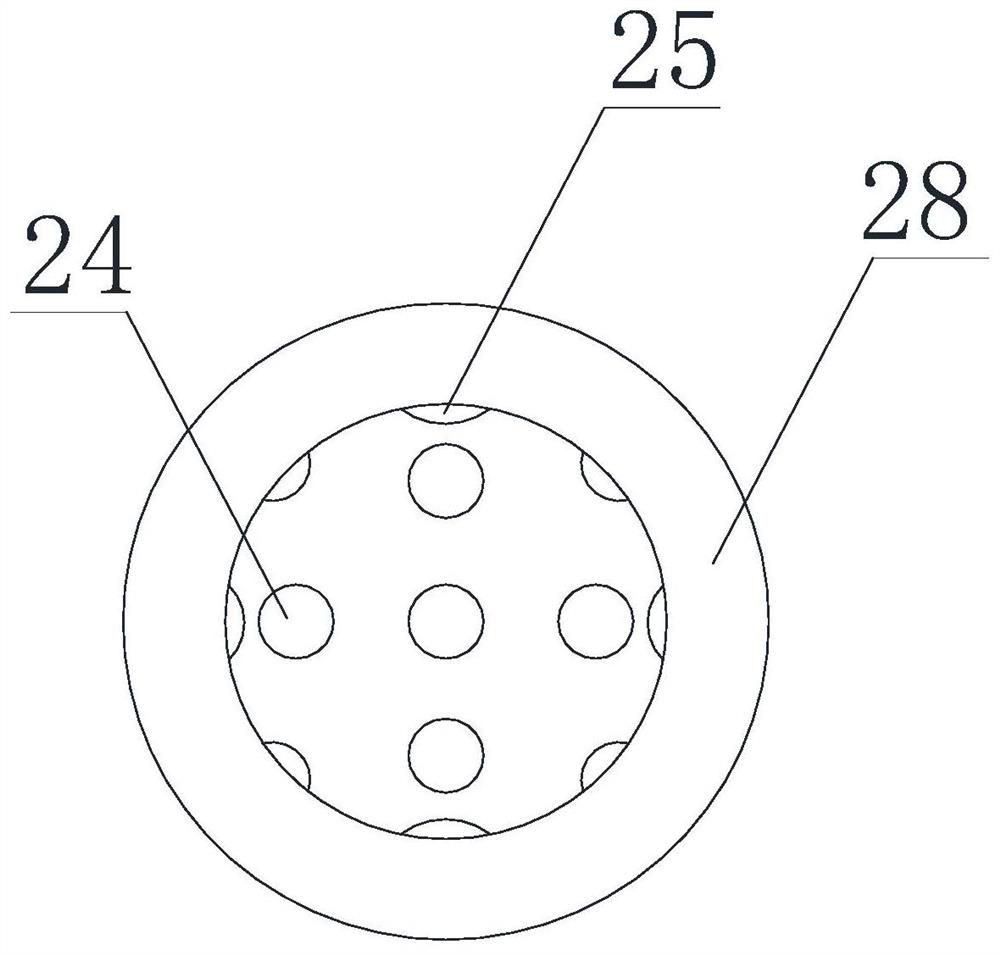

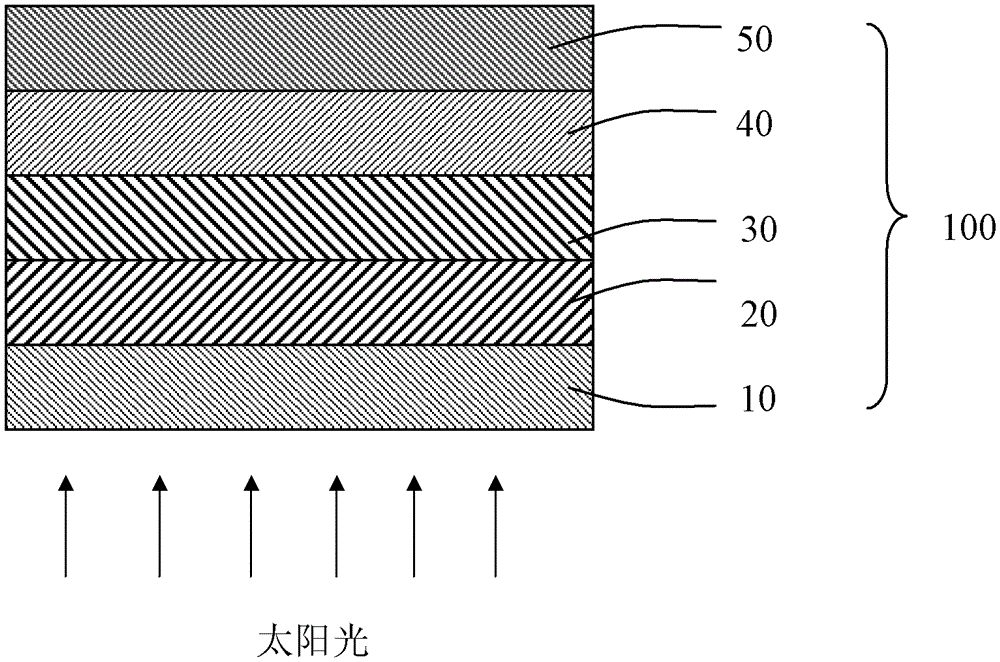

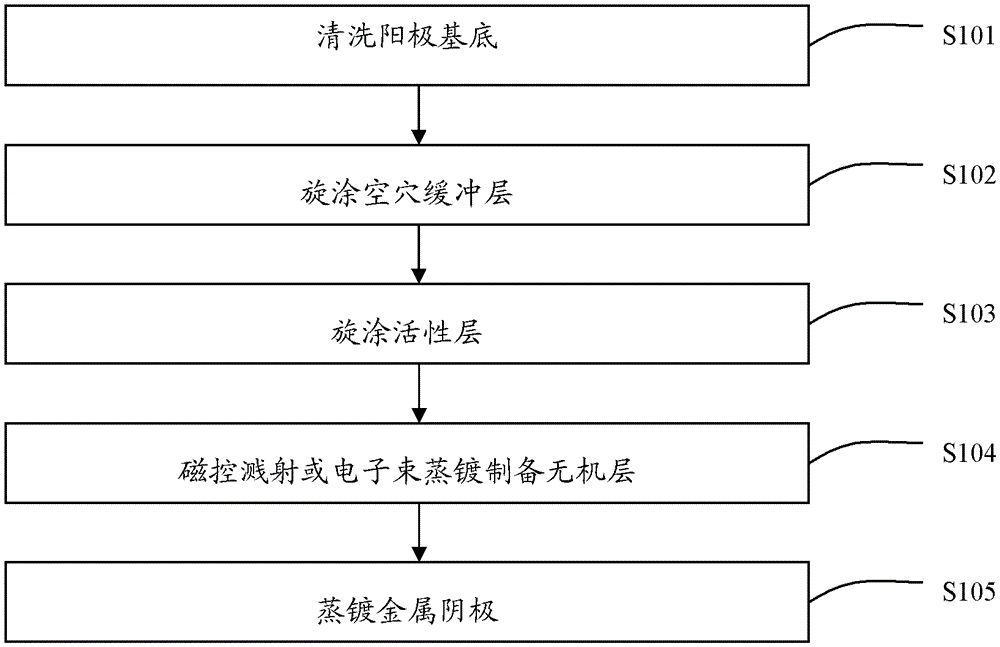

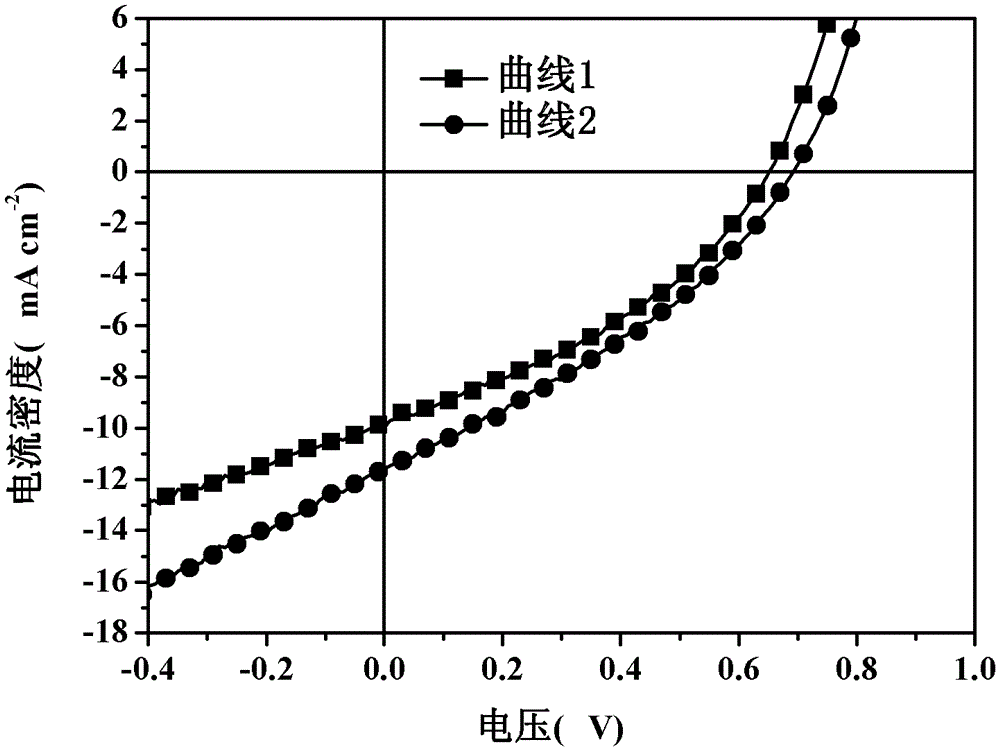

Polymer solar battery and preparation method thereof

ActiveCN102956826AImprove collection efficiencyImprove distributionSolid-state devicesSemiconductor/solid-state device manufacturingSolar batteryElectron

The invention relates to a polymer solar battery and a preparation method of the polymer solar battery. The polymer solar battery comprises an anode substrate, a cavity buffer layer, an active layer and a metal cathode which are sequentially stacked, and also comprises an inorganic layer arranged between the active layer and the metallic cathode.\The polymer solar battery comprises the active layer / inorganic layer structure, the distribution of an optical field in the active layer can be improved, so that a generating region of a carrier is changed, a good place is provided for exciton dissociation, and meanwhile, the transmission efficiency of the carrier is improved; and a contacting interface of the active layer and the cathode is separated, so that metal atoms are prevented from diffusing to the active layer to further destroy the structure of the active layer, the role of a buffering layer is played, and the collection efficiency of electrons at the position of the electrode is improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

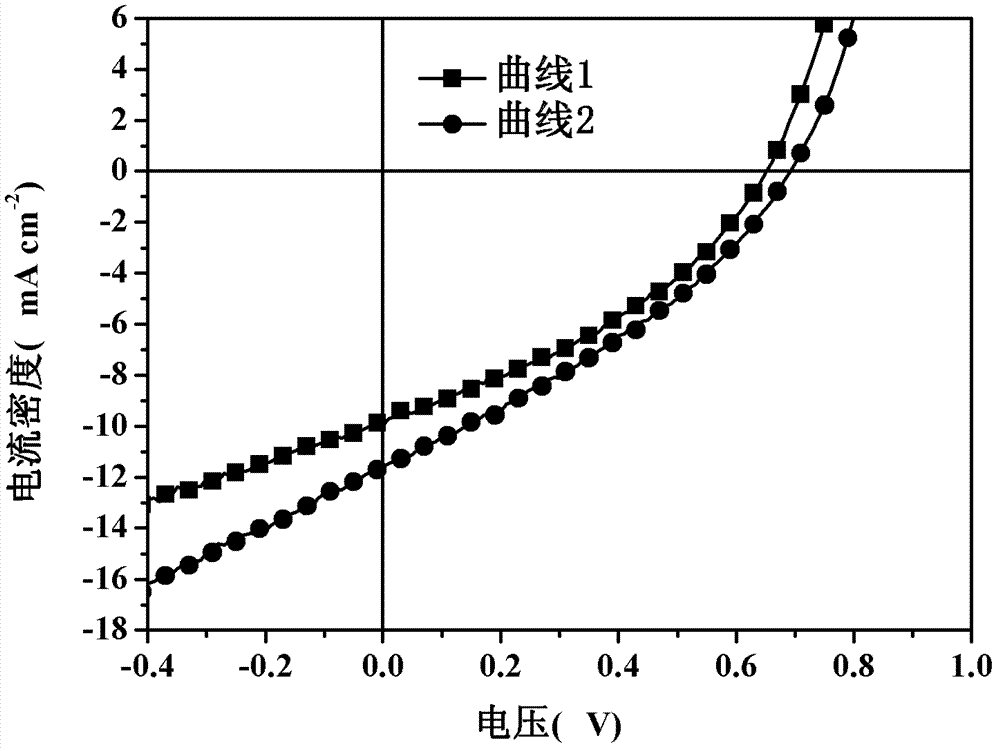

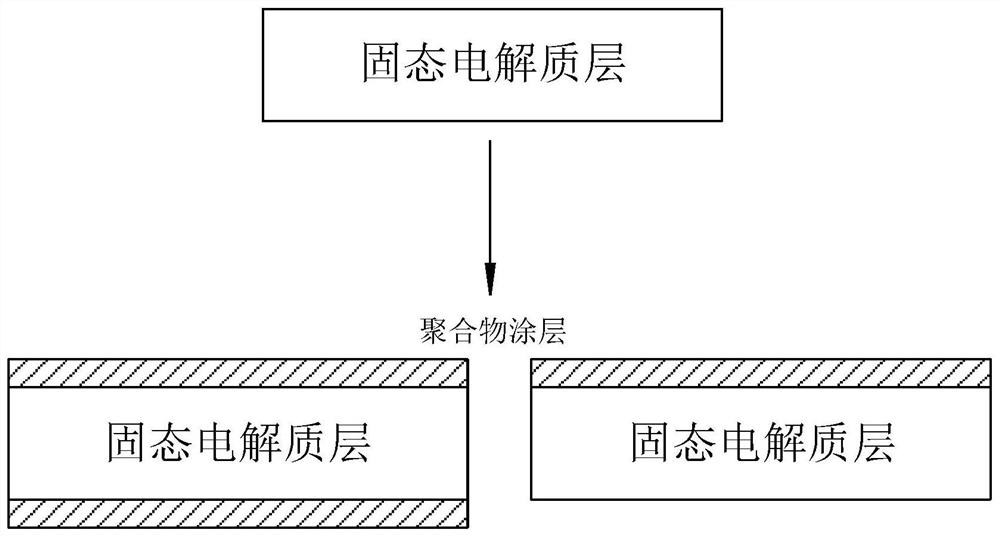

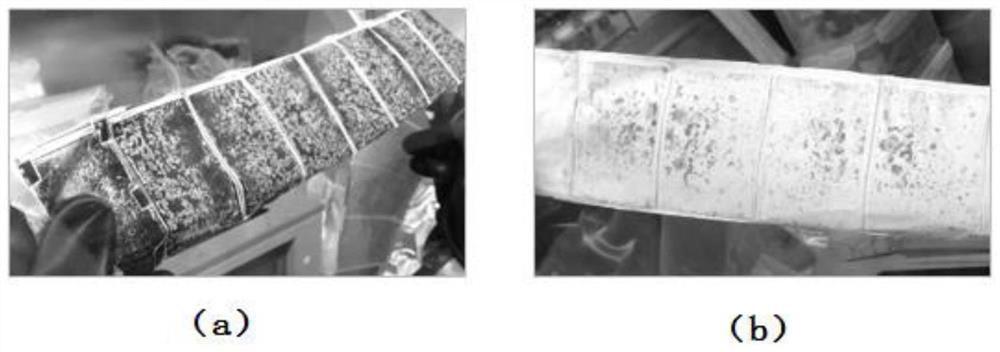

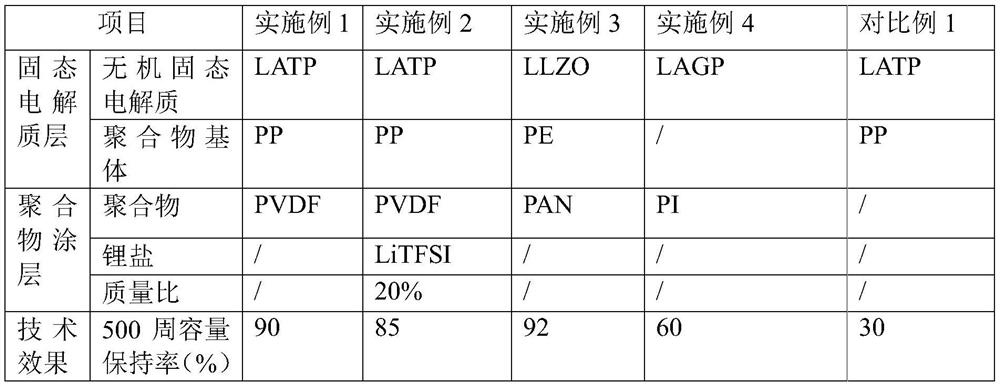

Composite electrolyte membrane, preparation method and application thereof, and solid-state lithium battery

ActiveCN112838266AImprove performanceImprove solid-solid contact problemsSolid electrolytesSecondary cells servicing/maintenanceSolid state electrolyteComposite electrolyte

The invention discloses a composite electrolyte membrane, a preparation method and application thereof, and a solid-state lithium battery. The composite electrolyte membrane comprises a solid electrolyte layer, wherein one side or two sides of the solid electrolyte layer are coated with a polymer coating; the solid electrolyte layer includes an inorganic solid electrolyte. The composite electrolyte membrane can reduce interface resistance, inhibit interface side reaction and relieve lithium deposition; the solid-state lithium battery based on the composite electrolyte membrane is good in cycle performance and good in safety.

Owner:SHANGHAI ELECTRICGROUP CORP

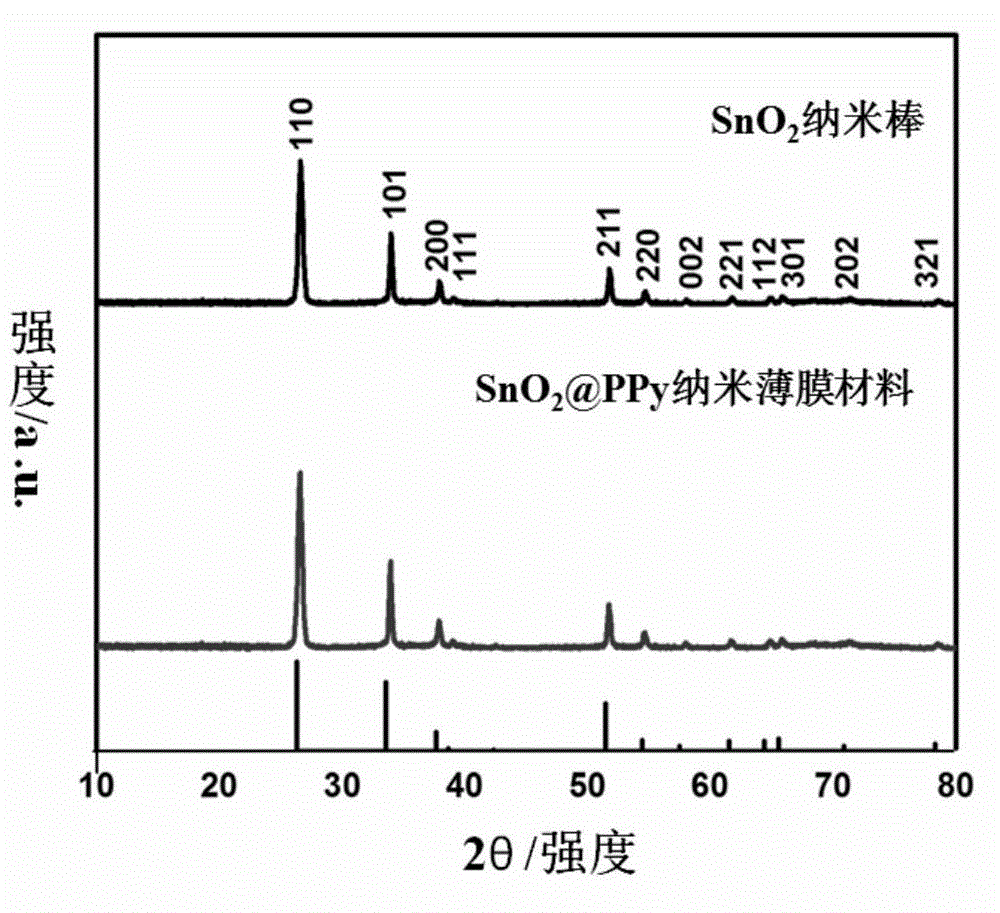

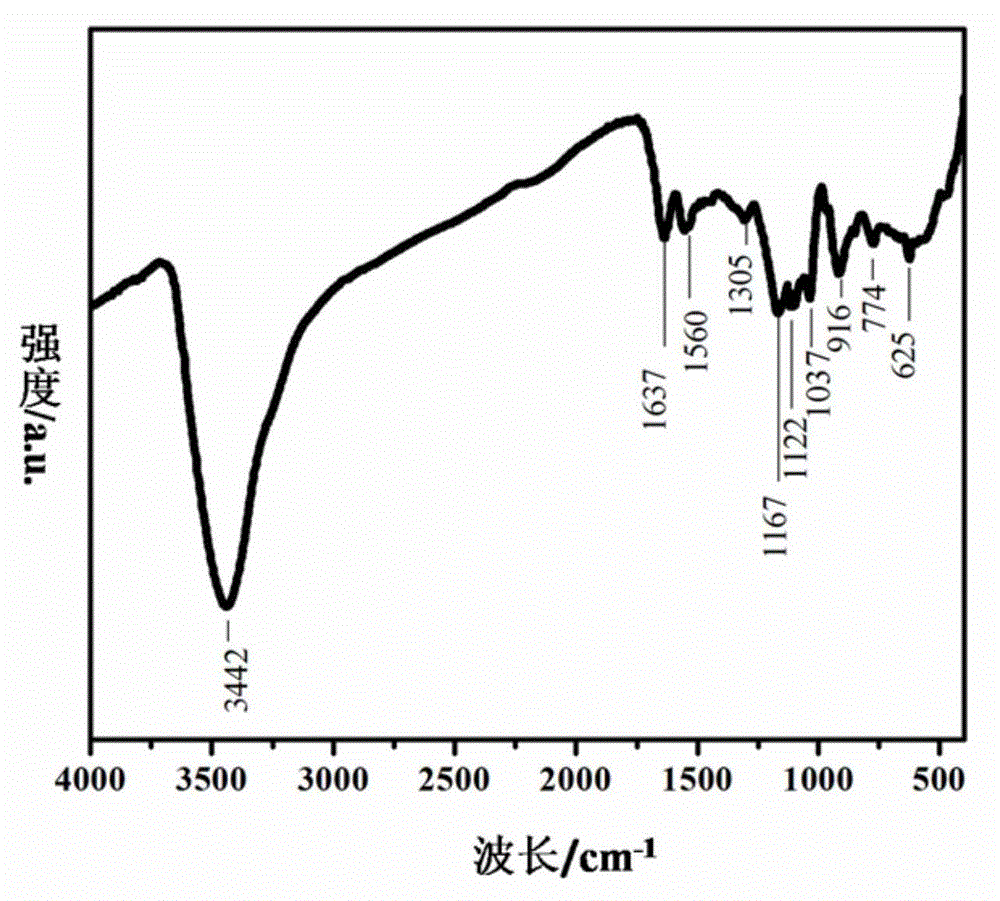

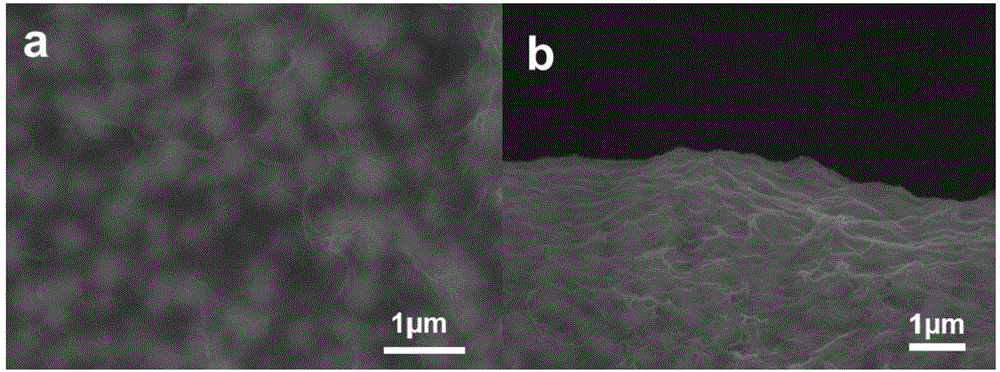

SnO2@PPy nano-film structural material as well as preparation method and application thereof

InactiveCN104600264AImprove conductivityAvoid structural damageMaterial nanotechnologyNegative electrodesPolymer sciencePyrrole

The invention relates to a SnO2@PPy nano-film structural material as well as a preparation method and application thereof. The SnO2@PPy nano-film structural material is formed by coating the surfaces of SnO2 nanorods growing on nickel foam with polymer pyrrole (PPy), wherein the thickness of the film formed by PPy is 0.8-1.5mu m and is prepared by the following method comprising the following steps: (1) dispersing pyrrole monomer in 50ml lithium perchlorate-acetonitrile solution, mixing and stirring for 30 minutes; (2) by taking nickel foam on which SnO2 nanorod arrays grow as a working electrode, Ag / AgCl as a reference electrode and a platinum electrode as a counter electrode, carrying out electrodeposition for 2000 seconds at a current density of 2.5mA / cm<2> and washing. The SnO2@PPy interconnection nano-sheet structural material has the beneficial effects that PPy grows on the surfaces of the SnO2 nanorods by adopting an electrochemical-deposition method so that the effect of a buffer layer can be achieved, the electrical conductivity of the material is increased and the cycling stability of the electrode material is improved.

Owner:WUHAN UNIV OF TECH

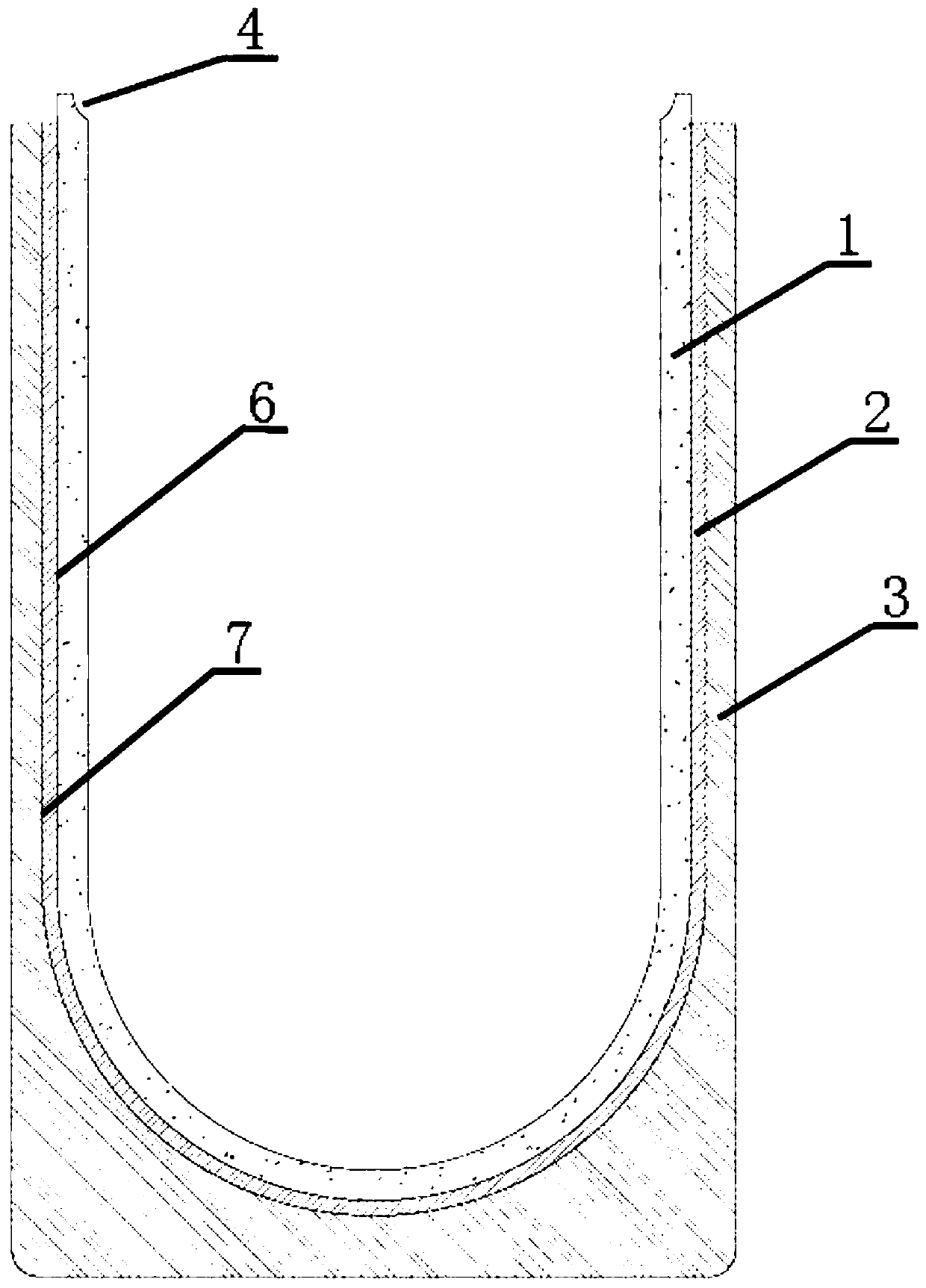

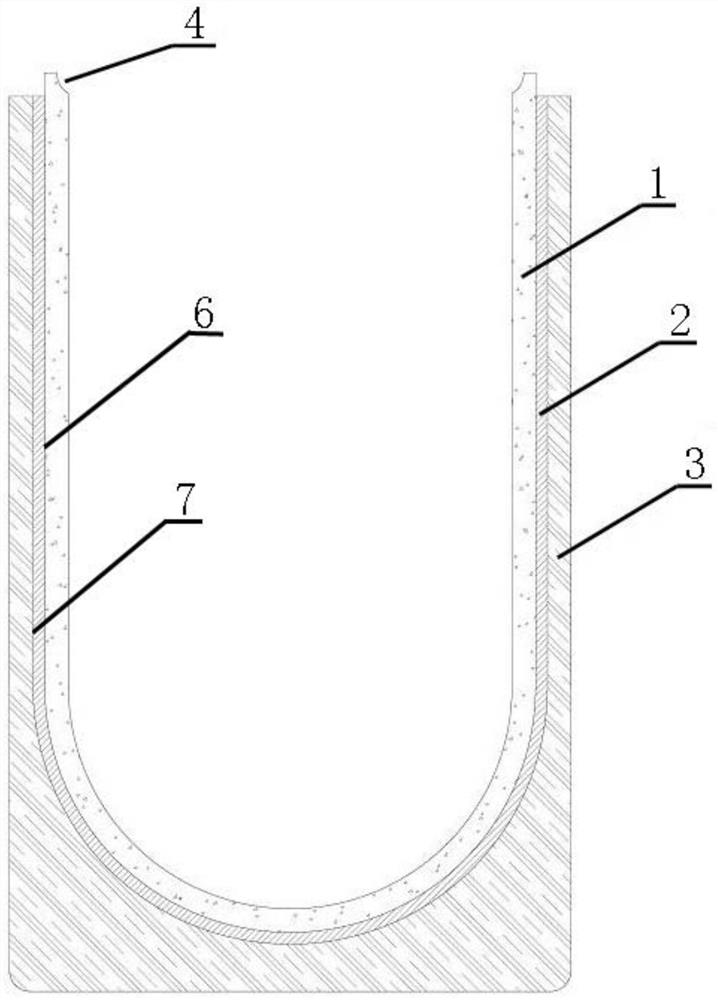

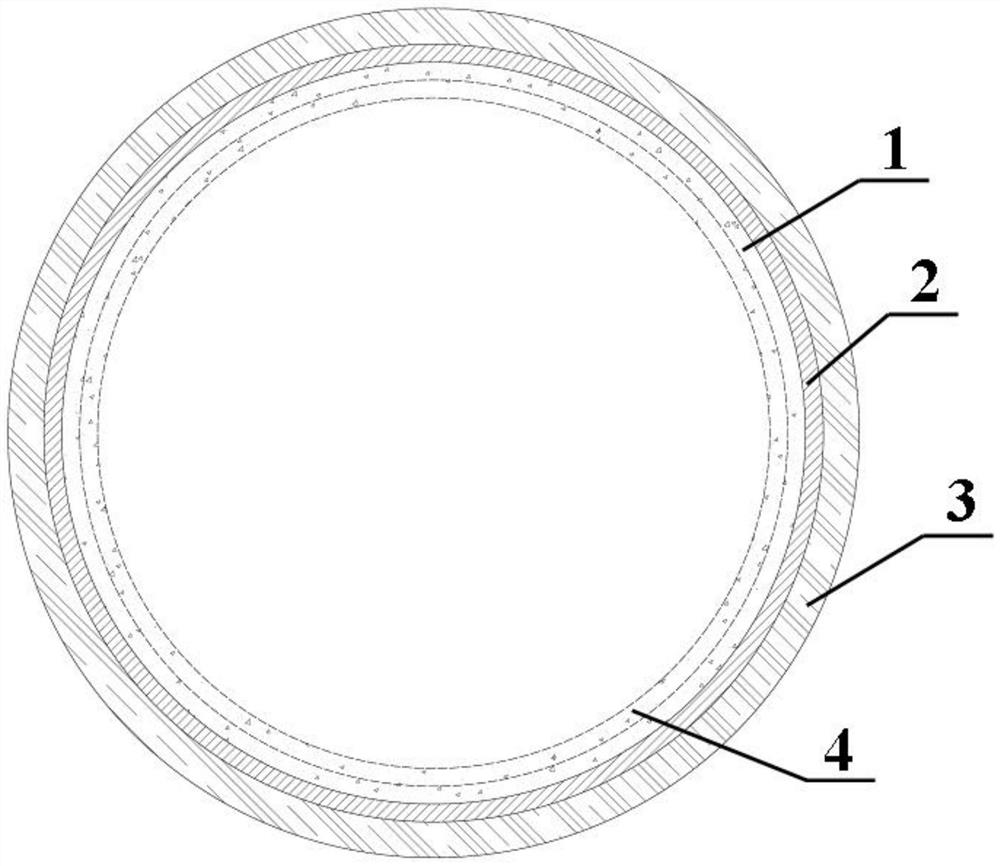

Composite multi-layer crucible for induction melting of bismuth aluminum alloy and preparation method thereof

ActiveCN109824370AImprove structural strengthChemically stableLayered productsCrucibleSmelting process

The invention discloses a composite multi-layer crucible for induction melting of a bismuth aluminum alloy and a preparation method thereof.The problem in the prior art thata crucible suitable for theinduction melting of the bismuth aluminum alloy does not exist is solved. The composite multi-layer crucible comprises an inner layer crucible, a middle layer crucible and an outer layer crucible which are fixedly connected from the inside to the outside; the inner layer crucible is prepared from 92.5-97.5 parts of cerium oxide, 1.0-2 parts of calcium oxide, 0.5-2.0 parts of bismuth oxide and 1.0-3.5 parts of silicon carbide; the middle layer crucible is made of graphite; the outer layer crucible is prepared from 90-95 parts of calcium oxide, 1-3 parts of magnesium oxide, 2-4 parts of ceriumoxide, 1-1.5 parts of zirconiaand 0.5-1.5 parts of clay. The composite multi-layer crucible has a high strength structure, can shield a considerable portion of an induced magnetic field, has stable chemical properties, and has no splashing phenomenon in the smelting process, the degree of oxygenation is low, some single-layer structures can be replaced and can be reused, and the service life is long.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

CF/PPS composite material with high impact toughness and preparation method thereof

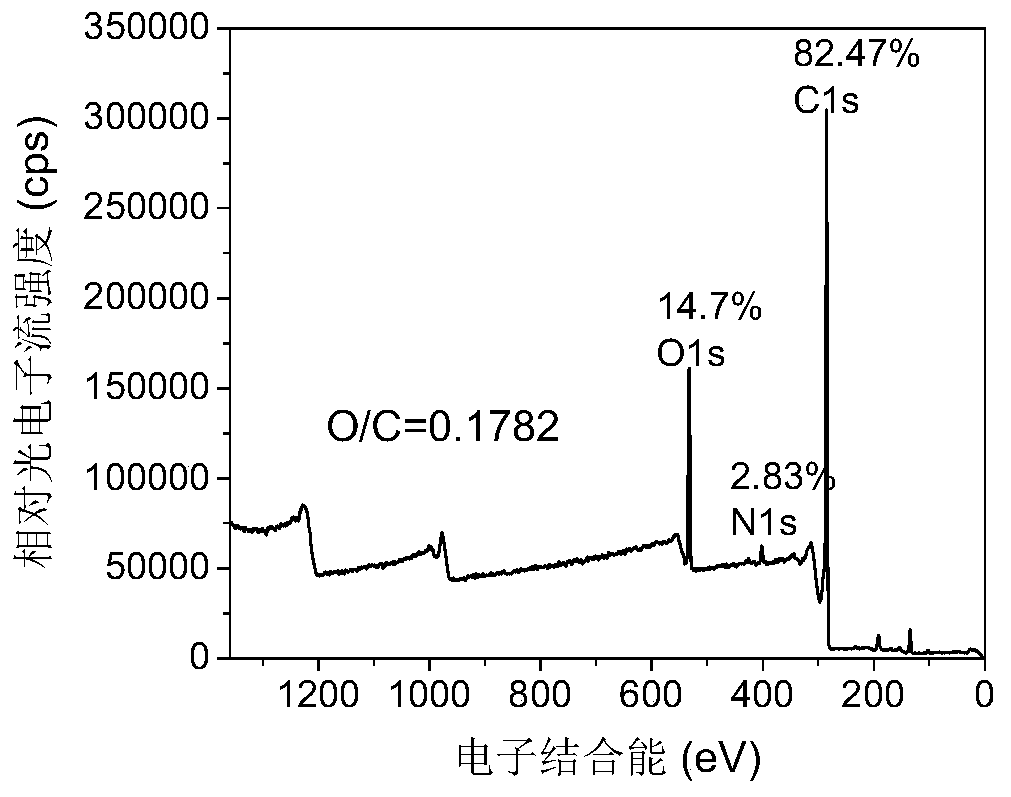

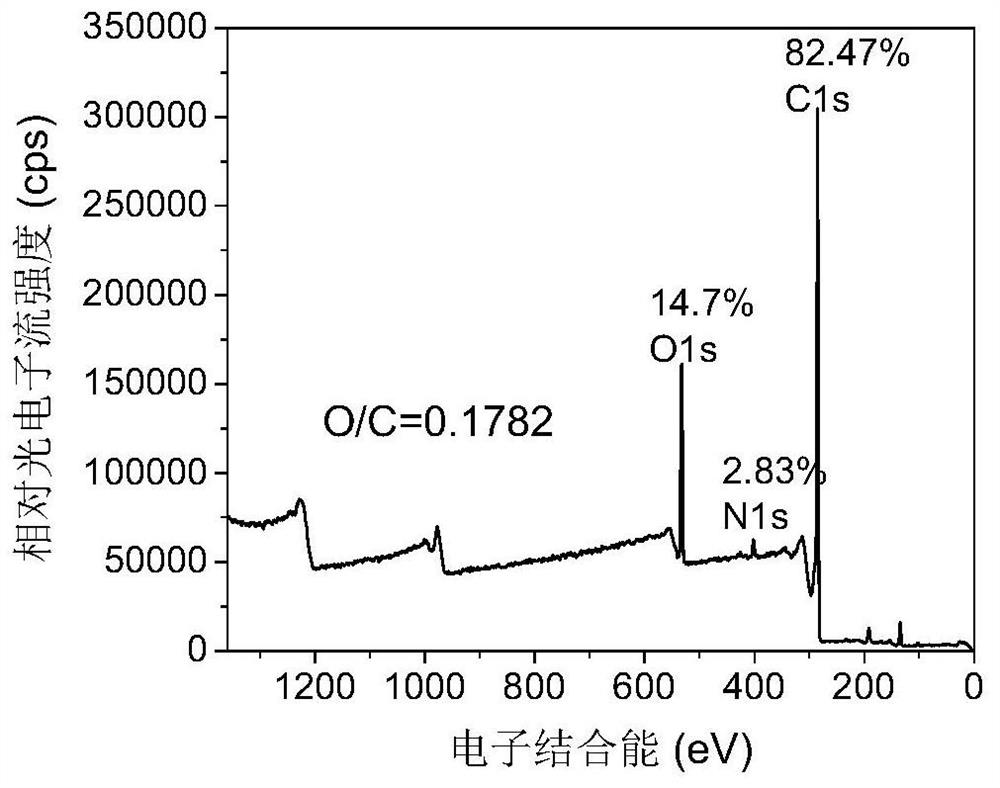

The invention relates to a CF / PPS composite material with high impact toughness and a preparation method of the CF / PPS composite material. The preparation method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing the ACF into polyether sulfone / dimethylformamide, and drying to obtain sized carbon fiber MCF; (4) laminating and hot-pressing the MCF anda PPS material; (5) cooling to a certain temperature at a rate of 50-70 DEG C / min after hot pressing is finished, applying a certain pressure, maintaining the pressure for a period of time, and then relieving the pressure to obtain the CF / PPS composite material with high impact toughness. The tensile strength of the composite material is 650-820 MPa, the tensile modulus of the composite material is 50-63 GPa, the interlaminar shear strength of the composite material is 60-80 MPa, and the residual compression strength of the composite material after impact is 260-300 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared composite material can replace metal to be applied to the fields of aerospace, machinery, automobiles, rail transit, petroleum transportation and the like.

Owner:合肥东华复材科技有限公司

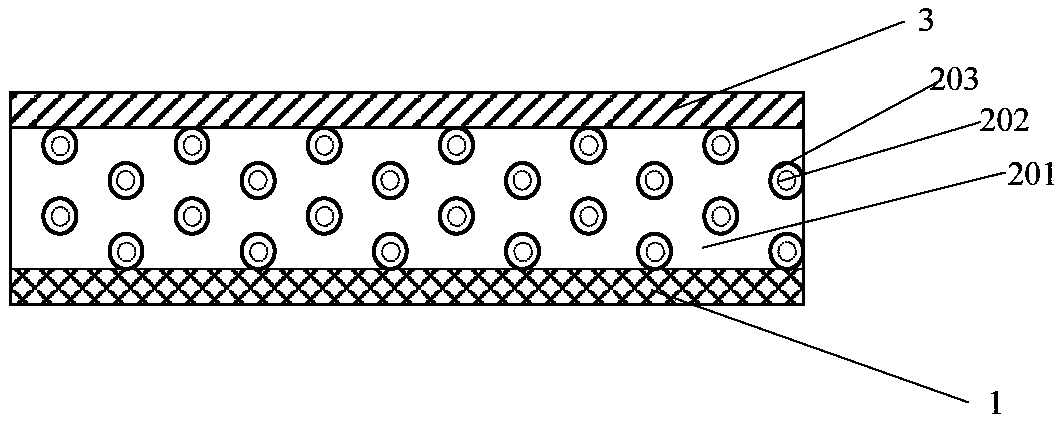

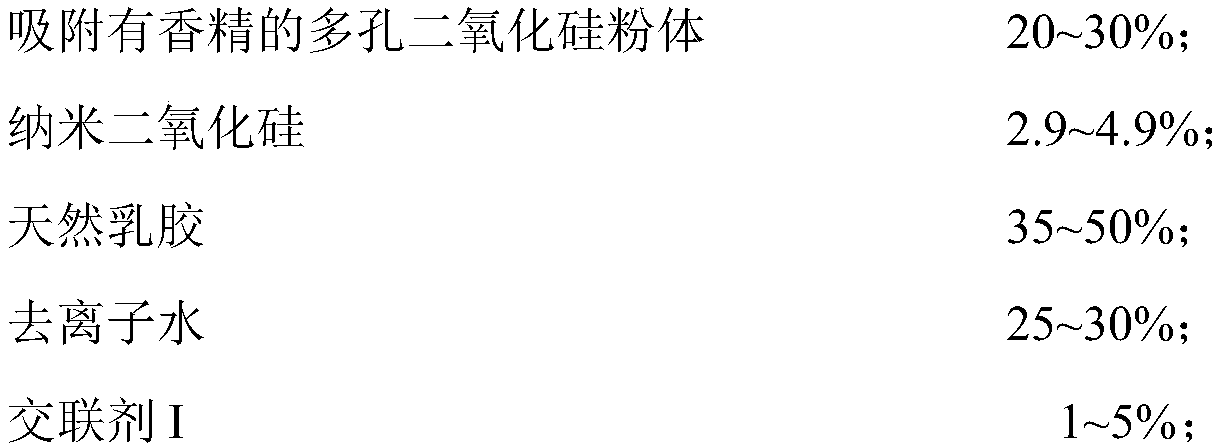

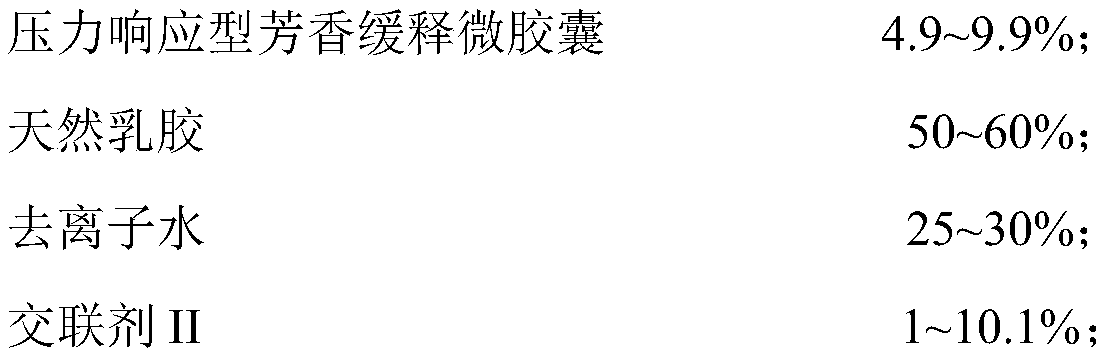

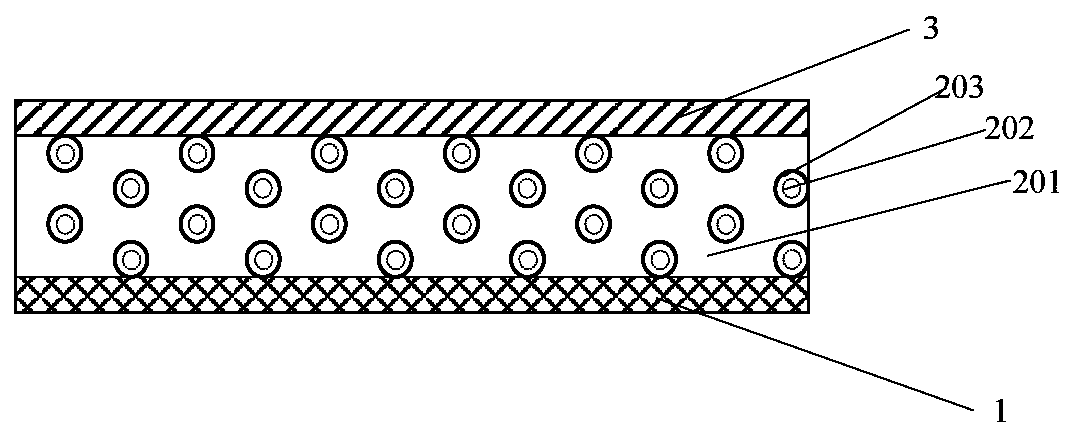

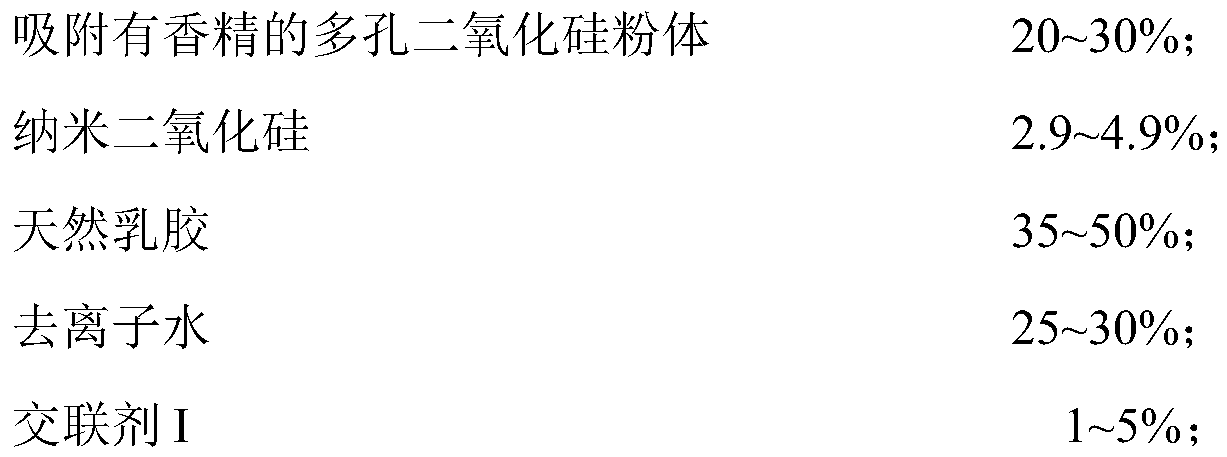

Pressure-responsive fragrant sustained-release microcapsule, and preparation method and application thereof

ActiveCN108816163ASpeed up churnAvoid affecting the sustained release effectEssential-oils/perfumesMicroballoon preparationCross-linkSilicon dioxide

The invention relates to a pressure-responsive fragrant sustained-release microcapsule, and a preparation method and an application thereof. The microcapsule comprises a core material and a wall material coated outside the core material. The preparation method comprises the following steps: dispersing an essence-adsorbed porous silicon dioxide powder into deionized water under stirring, adding nanometer silicon dioxide, natural latex and a cross-linking agent I for cross-linking so as to prepare the pressure-responsive fragrant sustained-release microcapsule. The pressure-responsive fragrant sustained-release microcapsule is applied through the following steps: adding the natural latex into the prepared microcapsule, then adding a cross-linking agent II and the deionized water, carrying out uniform dispersing, injecting a dispersion into a mold, carrying out drying, cross-linking and cooling so as to prepare an elastic material, and coating an EVA hot melt adhesive onto two sides of the elastic material so as to prepare an elastic carpet. According to the invention, the preparation method is simple; raw materials are easily-available; and the essence release speed of the fragrant sustained-release microcapsule has a certain relationship with the pressure that the fragrant sustained-release microcapsule bears, so the release effect of an essence in the interior of the microcapsule is effectively improved; the usage amount of perfumes is saved; the service life of the carpet is prolonged; and significant application prospects are achieved.

Owner:DONGHUA UNIV

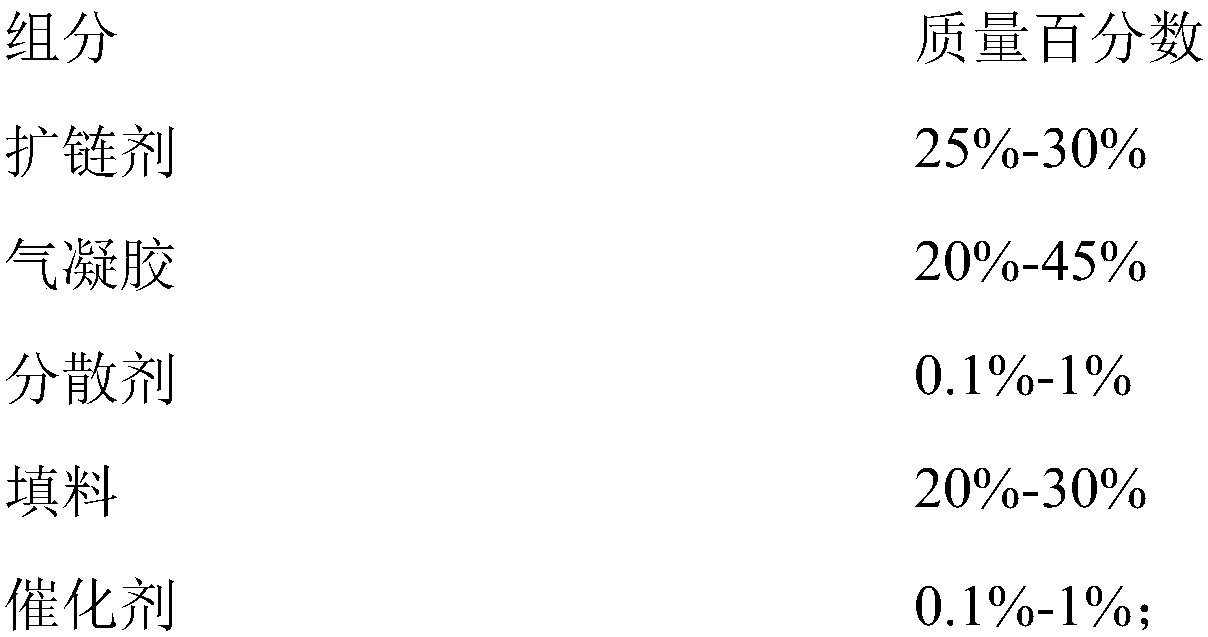

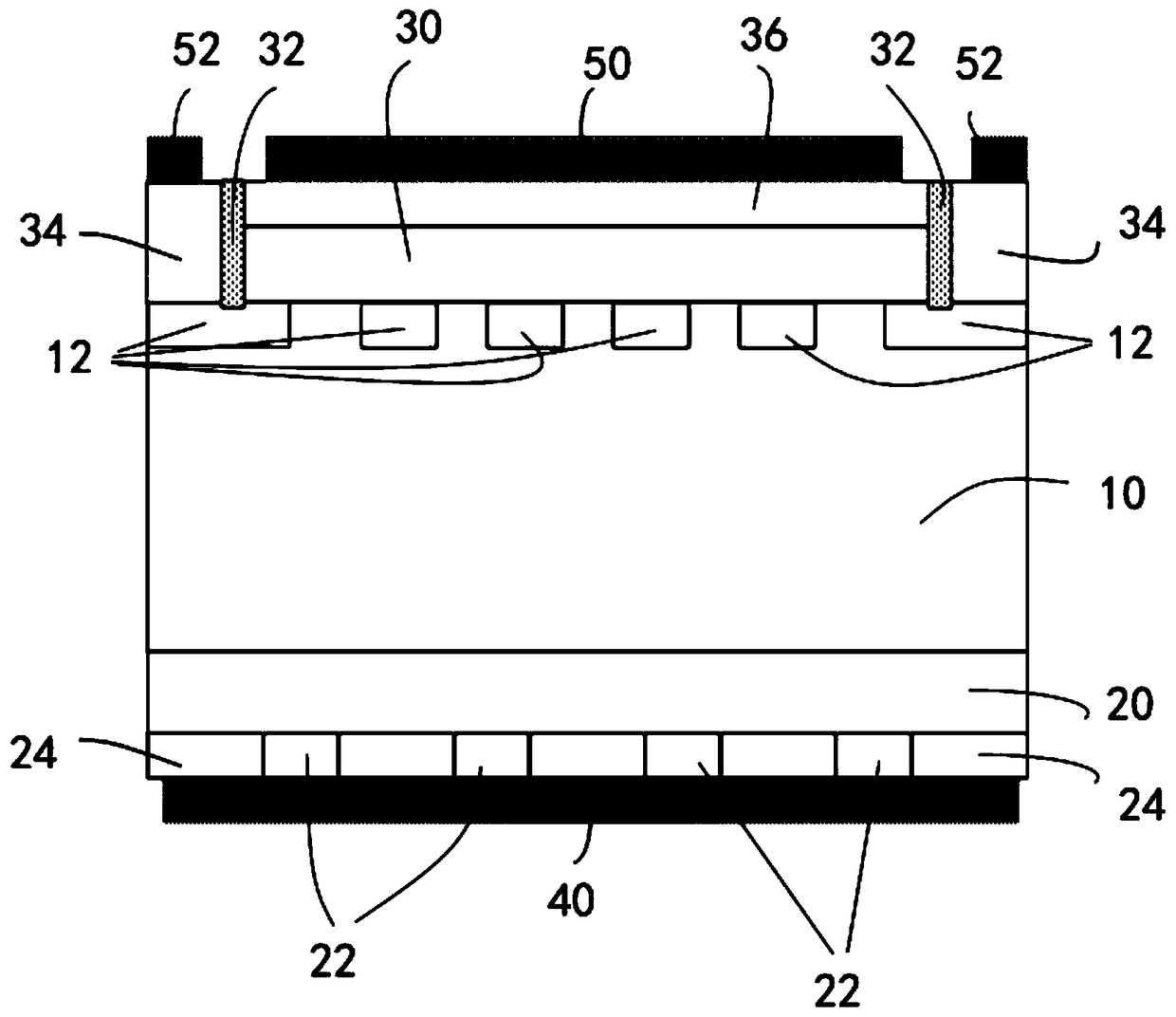

Bulletproof polyurethane-fiber composite material and preparation method thereof

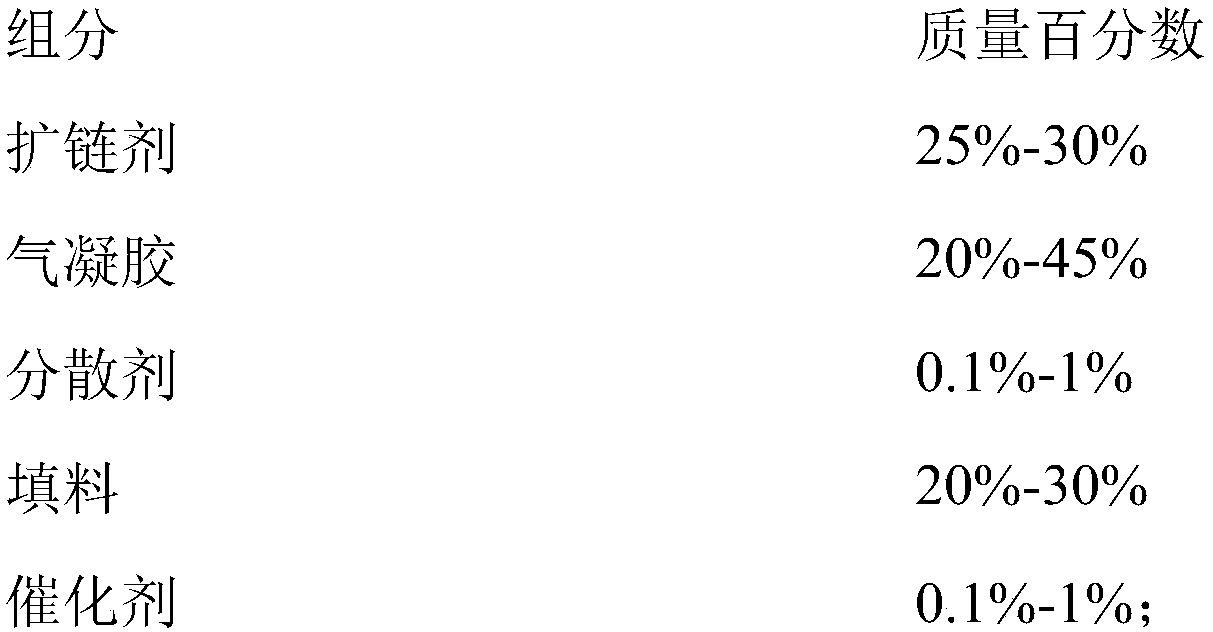

The invention relates to the field of bulletproof materials and discloses a bulletproof polyurethane-fiber composite material and a preparation method thereof. The polyurethane-fiber composite material comprises the following components in percent by weight: 20wt.%-60wt.% of fiber and 40wt.%-80wt.% of polyurethane composition, wherein the polyurethane composition is prepared by mixing a componentA and a component B according to the volume ratio of 1-10:1; the component A is isocyanate prepolymer synthesized by 40wt.%-60wt.% of isocyanate and 40wt.%-60wt.% of polymer polyol; the component B isprepared by mixing 25wt.%-30wt.% of chain expanding agent, 20wt.%-45wt.% of aerogel, 0.1wt.%-1wt.% of dispersing agent, 20wt.%-30wt.% of filler and 0.1wt.%-1wt.% of catalyst. The polyurethane-fiber composite material and the preparation method disclosed by the invention have the beneficial effects that the instantaneous deformation resistance and capability of responding to bad weather environment of a bulletproof plate can be enhanced, and better protection can be provided for the material and structure of a bullet inserting plate, so that the protective capability and the service life of the bulletproof plate are improved; simultaneously, due to good toughness of the polyurethane material, certain buffering-layer action also can be achieved, and the damage caused by deformation of the bulletproof inserting plate can be reduced.

Owner:长沙盾甲新材料科技有限公司

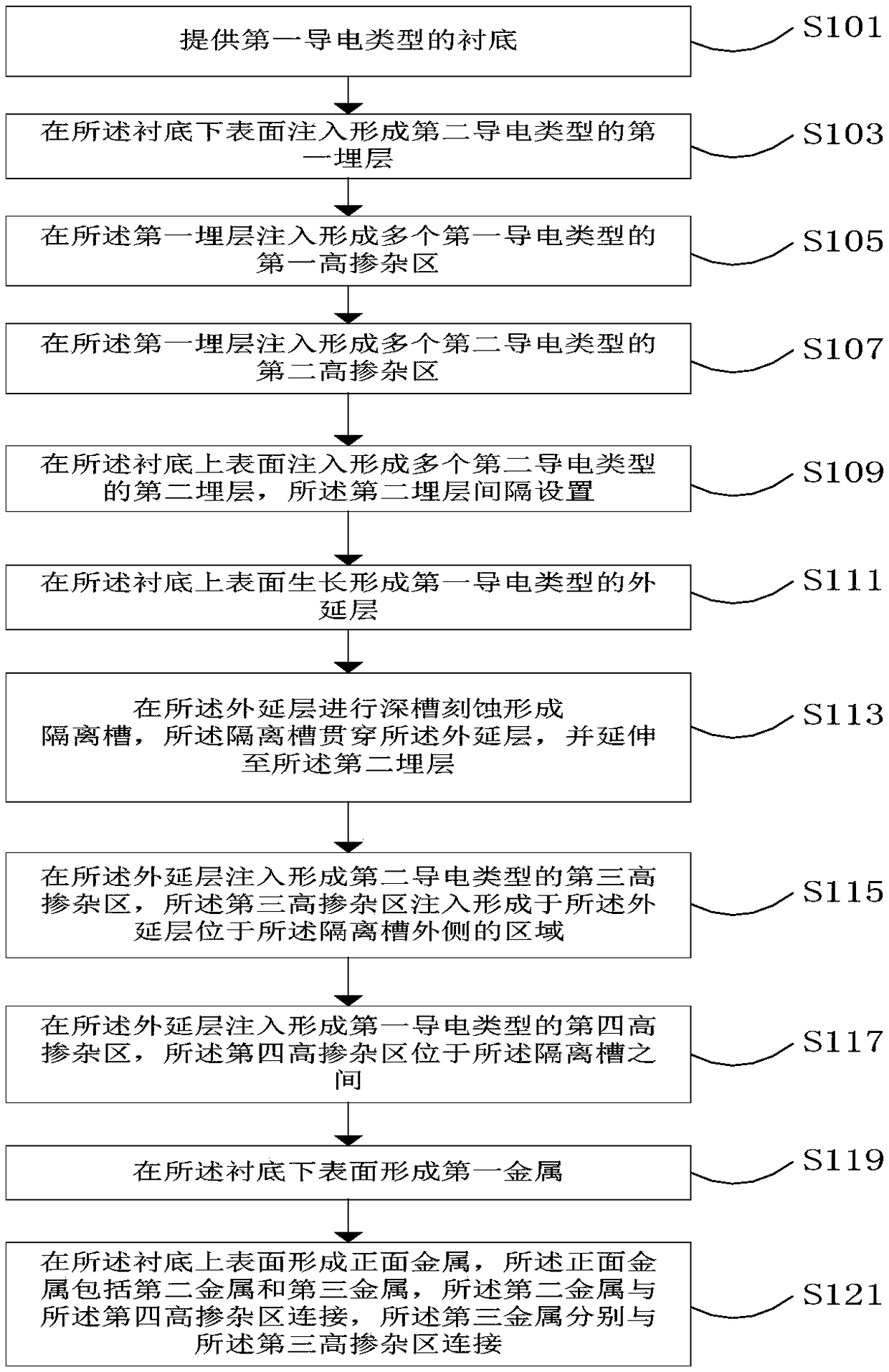

Static induction thyristor and manufacturing method thereof

InactiveCN109449205AReduce switching lossesReduce power consumptionThyristorSemiconductor/solid-state device manufacturingReverse recoveryVoltage drop

The invention provides a static induction thyristor and a manufacturing method thereof, and solves the problem that an SITH obtained in the prior art cannot meet the latest use requirements. A first highly-doped region is added to a positive electrode region of a device, so that a parasitic transistor is formed; the conduction voltage drop of the SITH is reduced, and meanwhile, the injection efficiency of a positive electrode is reduced by the first highly-doped region of the positive electrode region, so that the reverse recovery time is shortened, and the reverse recovery charge is also obviously reduced; and the final SITH device has a higher switching speed and lower switching loss. An epitaxial layer is also added between a fourth highly-doped region and a substrate, so that the effect of a buffer layer is achieved; during the reverse recovery period, the electric field intensity of the substrate and the epitaxial layer is reduced and the extraction speed of carriers is reduced, so that high-voltage oscillation is remarkably reduced, and a softer recovery characteristic is obtained; and the reverse recovery charge is less, so that the power consumption of the device is furtherreduced.

Owner:中健共创(深圳)大健康产业投资有限公司

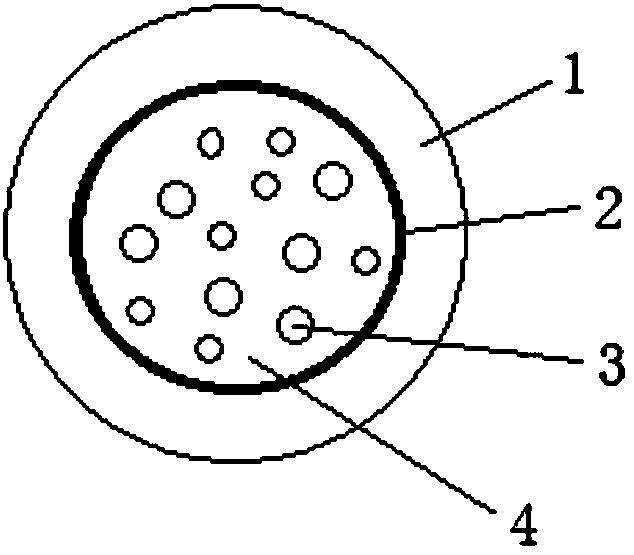

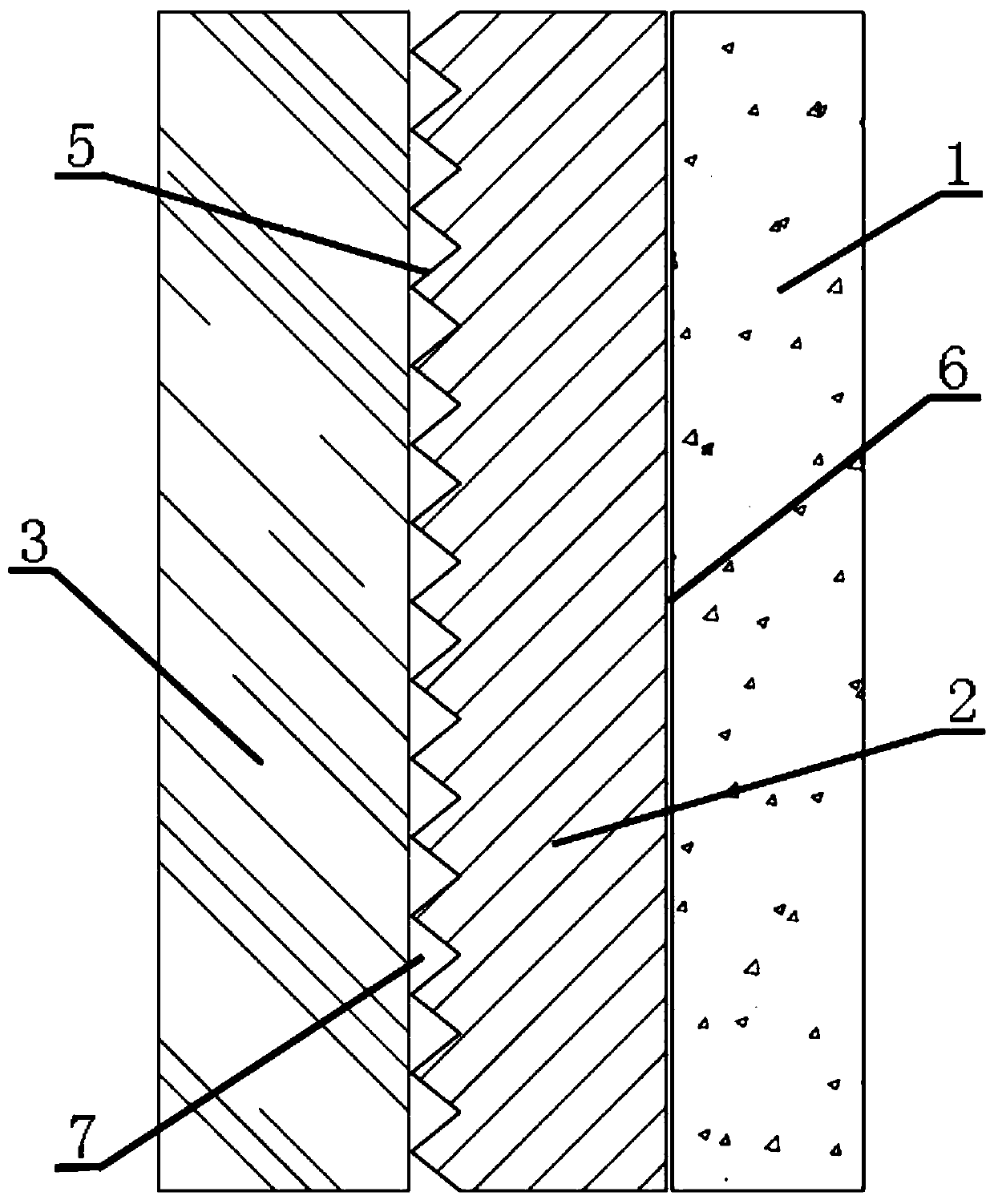

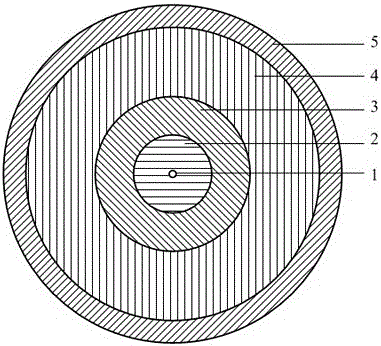

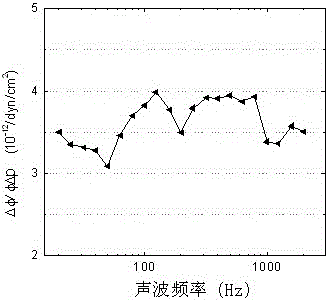

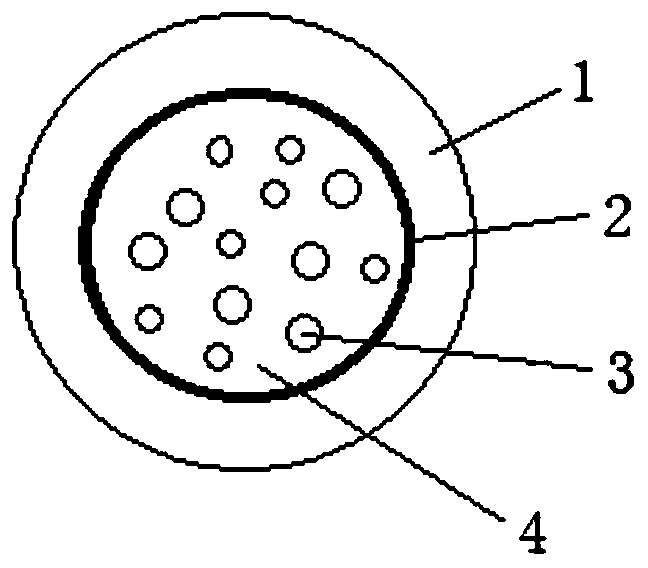

A kind of vibration sensitive optical fiber and its manufacturing method

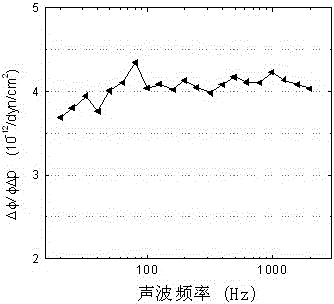

ActiveCN104049298BHigh vibration sensitivityAct as a buffer layerGlass making apparatusCladded optical fibreMonitoring systemYoung's modulus

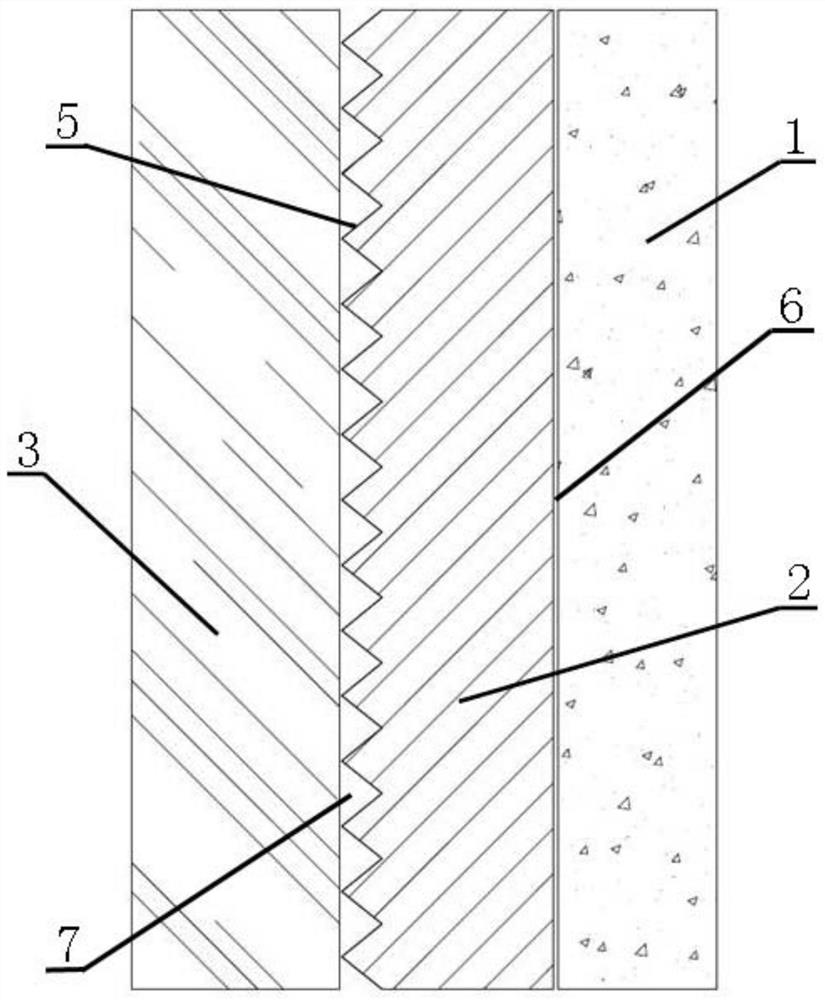

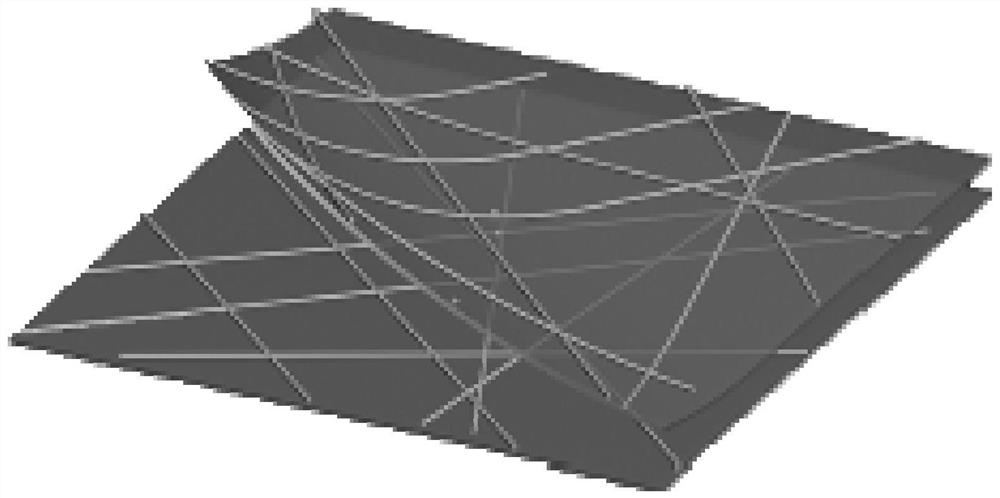

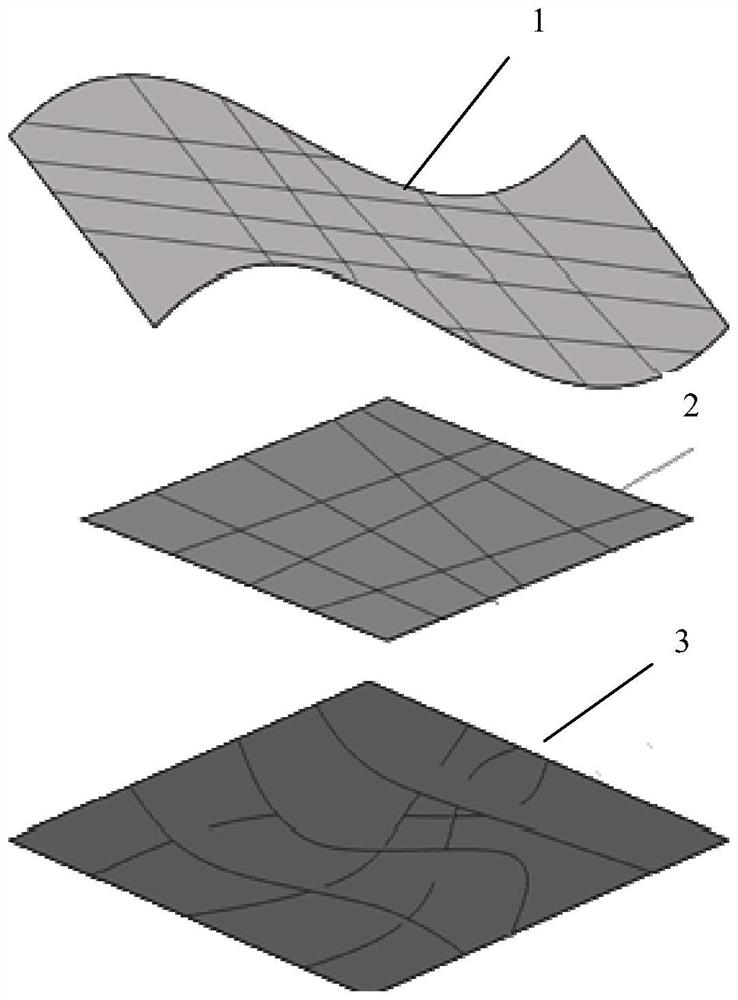

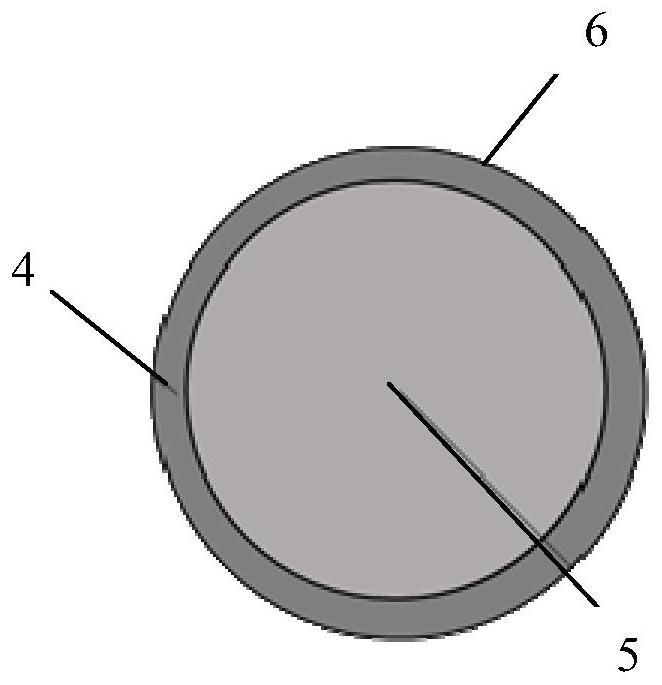

The invention relates to a vibration-sensitive optical fiber and a manufacturing method thereof, belonging to the technical field of optical fibers. The vibration-sensitive optical fiber includes a core, a silica cladding coated on the outside of the core, and a medium modulus coating coated on the outside of the silica cladding. The Young's modulus of the medium modulus coating after curing is between Between 50MPa and 200MPa, the single side wall thickness of the medium modulus coating layer is between 70 μm and 150 μm, and the vibration sensitizing layer is coated on the outside of the medium modulus coating layer. The invention adopts a layer of medium modulus coating layer to replace the low modulus inner coating layer and high modulus outer coating layer of ordinary commercially available optical fibers, and uses high elasticity as the vibration sensitization layer, which can effectively improve the optical fiber's resistance to vibration. The sensitivity of sound and other mechanical vibrations improves the performance of optical fibers as vibration and sound sensing media, thereby improving the sensitivity of the corresponding detection and monitoring systems.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

A silicon-carbon negative electrode material with core-shell structure and preparation method thereof

ActiveCN107863512BSolve the disadvantages of low first-time Coulombic efficiencyInhibition of volume changeCell electrodesSecondary cellsGraphiteSodium silicate

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Shell and manufacture method thereof

InactiveCN102485936AImprove corrosion resistanceImprove decorative appearanceVacuum evaporation coatingSputtering coatingSputteringMagnesium nitride

The invention provides a shell which comprises a magnesium or magnesium alloy matrix, an anticorrosion layer formed on the surface of the magnesium or magnesium alloy matrix and a color layer formed on the surface of the anticorrosion layer, wherein, the anticorrosion layer comprises a magnesium layer and a magnesium nitride layer, which are sequentially formed on the surface of the magnesium or magnesium alloy matrix, and the shell has good corrosion resistance and a decorative appearance. The invention also provides a manufacture method for the shell. The method comprises the following steps: providing the magnesium or magnesium alloy matrix; forming the anticorrosion layer on the magnesium or magnesium alloy matrix through magnetron sputtering, wherein the anticorrosion layer comprises the magnesium layer and the magnesium nitride layer, which are sequentially formed on the surface of the magnesium or magnesium alloy matrix; and forming the decorative color layer on the anticorrosion layer through magnetron sputtering.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Wide-range high-toughness nanoscale conductive rubber sensor, preparation method thereof and packaging method thereof

ActiveCN112388889ACompact structureImprove high pressure performanceDomestic articlesPhysical chemistryPolymer chemistry

The invention relates to the technical field of pressure measurement, and provides a wide-range high-toughness nanoscale conductive rubber sensor, a preparation method thereof and a packaging method thereof. The preparation method adopts a high-temperature internal mixing method to improve the dispersion of conductive filler, and a sandwich structure is cured under a high-pressure condition, so that a rubber structure is more compact. The nanoscale conductive rubber sensor prepared according to the preparation method is wide in measurement range, high in sensitivity, and high in stability. According to the wide-range high-toughness nanoscale conductive rubber sensor, the preparation method thereof and the packaging method thereof, a rubber matrix is used for packaging the nanoscale conductive rubber sensor, and a case, a cover plate and a sealing cover are used for sealing the rubber matrix packaged with the sensor so as to achieve an ingenious packaging structure. Therefore, the sensor is stressed in a balanced manner, and the situation of structural damage caused by stress concentration is avoided. Meanwhile, through the packaging of the rubber matrix, the whole sensor has the excellent characteristics of high-temperature resistance, water resistance, fire resistance, ultraviolet resistance, acid and alkali corrosion resistance and the like, and is better in aging-resistant stability, and longer in service life and high in safety under a high-load condition.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

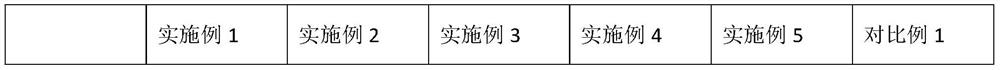

Bacteria filter bag with good filter effect and preparation method thereof

InactiveCN113599912AImprove filtering effectImprove adsorption capacityMembrane filtersFiltration separationMicrospherePolystyrene

The invention discloses a bacteria filter bag with a good filter effect and a preparation method thereof. The preparation method comprises the four steps of: preparing chitosan microspheres, preparing quaternized chitosan microspheres, preparing polystyrene cross-linked quaternized chitosan microspheres and preparing the bacteria filter bag. The quaternized chitosan microspheres provided by the invention have a rich pore structure, can effectively adsorb bacteria in the process of filtering bacteria, achieve an antibacterial purpose by inhibiting the growth of cells, and meanwhile, release xanthan gum to break the cells of the bacteria so as to achieve an antibacterial effect. In addition, the introduction of SiO2 can effectively protect the morphology of the quaternized chitosan microspheres, the porous structure of the quaternized chitosan microspheres provides an accommodation place for redundant bacteria and plays a role of a buffer layer, and sterilization and bacteriostasis are achieved while bacteria are filtered.

Owner:深圳市斯达辉科技有限公司

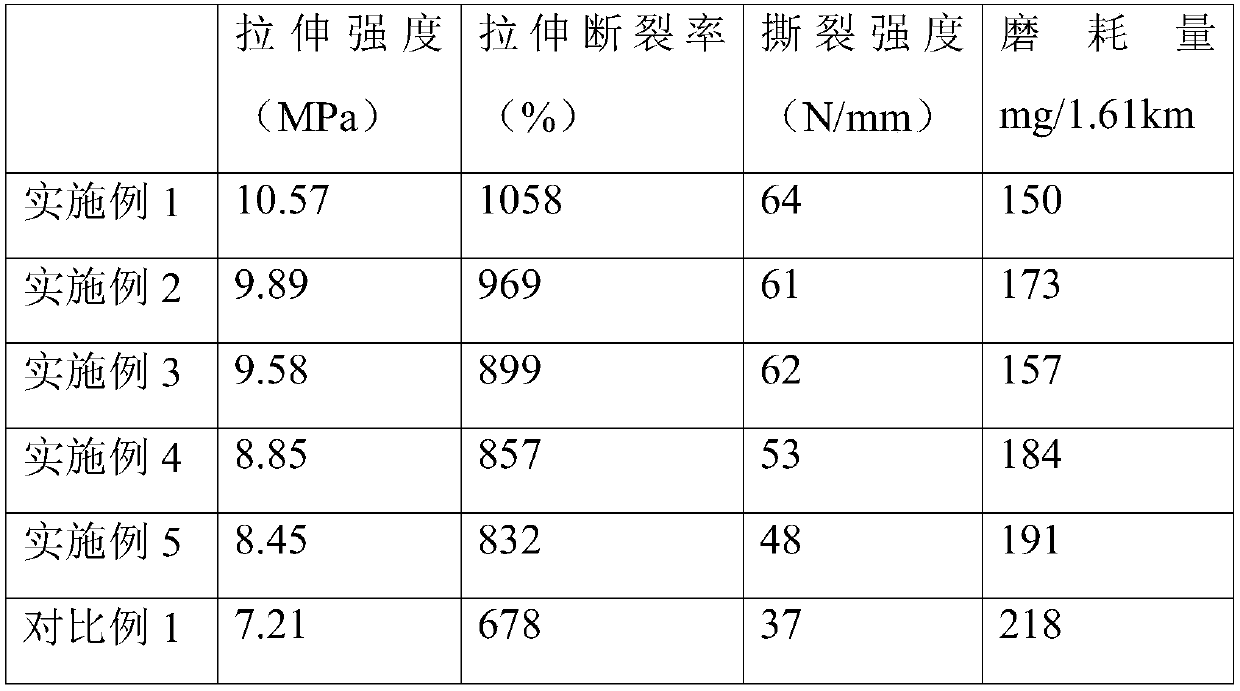

A packaging structure and packaging method for improving the mechanical strength of frit packaging

ActiveCN106206474BImprove package strengthImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesButt jointFrit

The invention discloses an encapsulating structure and method for improving Frit encapsulating mechanical strength. A metal film layer is made on a substrate; a Frit encapsulating layer and inorganic quantum dot nano-film layers are prepared on an encapsulating area of cover plate glass; the cover plate glass and an encapsulating area of the substrate are subjected to butt joint; a light source is used for illuminating the cover plate glass and the encapsulating area of the substrate, and the cover plate glass and the substrate are welded and sealed. According to the encapsulating structure and method for improving the Frit encapsulating mechanical strength, the Frit encapsulating strength is enhanced through the inorganic quantum dot nano-film layers, the fused Frit encapsulating layer can permeate into gaps of the nano-film layers, a glass material and nano-film layer composite enhancing system is formed, the welding strength is improved, and the adhesion of the Frit encapsulating layer and the cover plate glass is improved; meanwhile, the uniform and compact film layers formed by the inorganic quantum dot nano-film layers can perform the action of a buffer layer and the action of releasing stress when the cover plate glass is extruded; absorption of lasers can be increased through quantum dots, a smaller laser welding Frit encapsulating layer can be adopted, and the thermal stress impact of a screen body is reduced.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

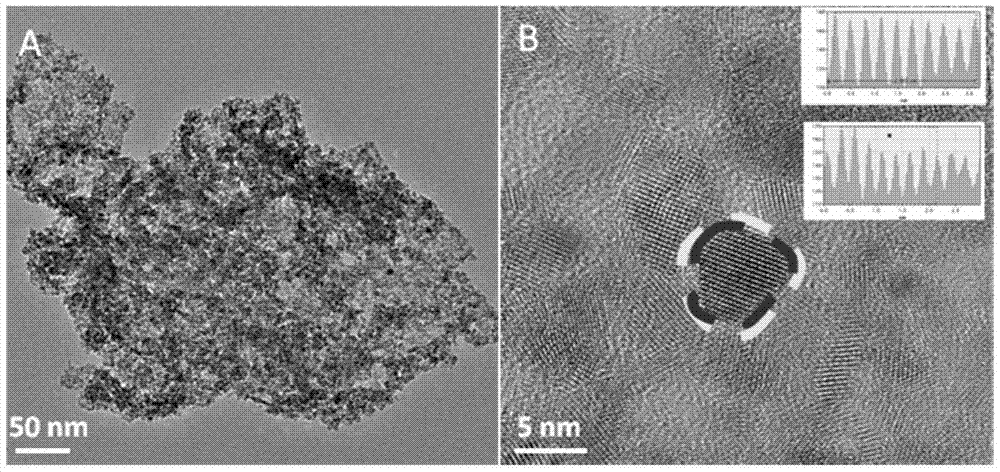

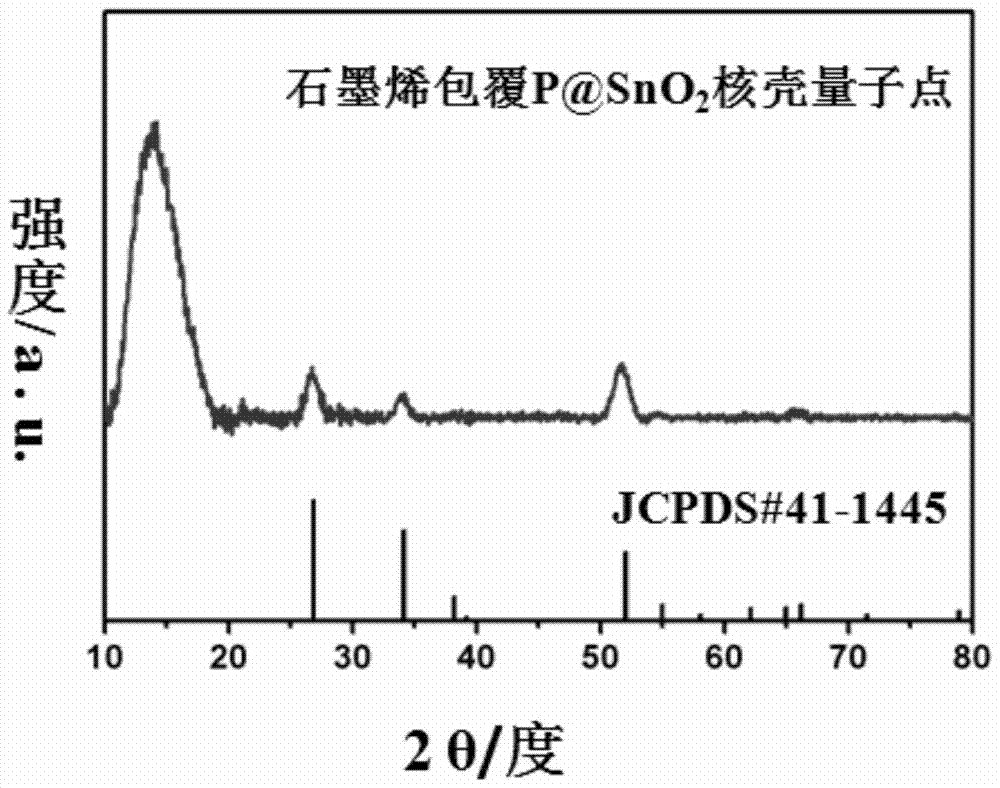

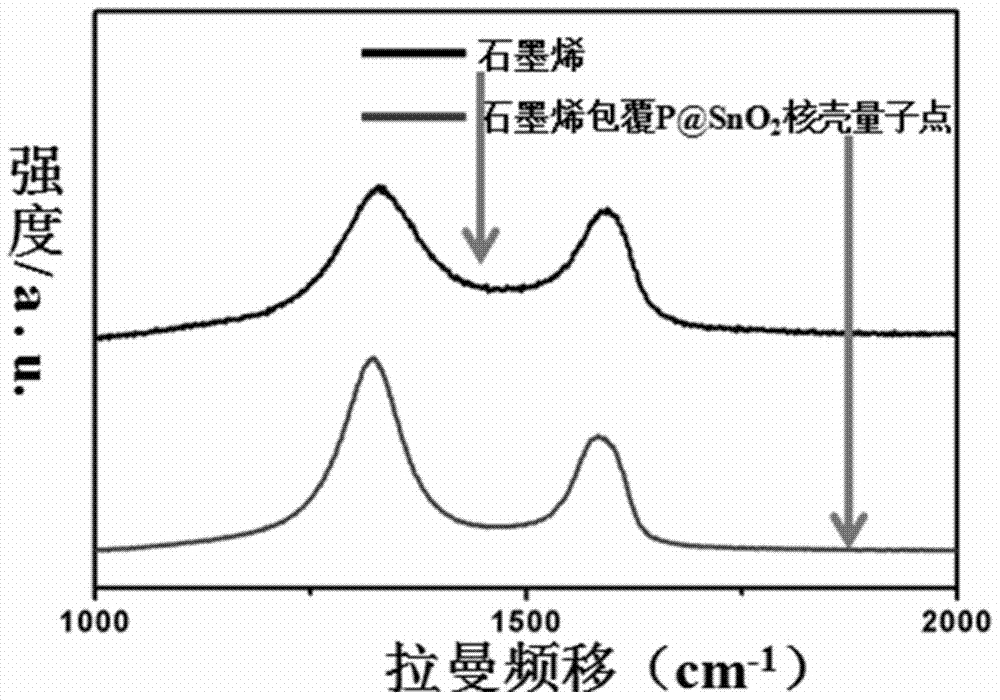

Graphene coated p@sno 2 Core-shell quantum dot electrode material and its preparation method and application

ActiveCN105226246BGuaranteed stabilityImproves ion/electron transport capabilitiesCell electrodesSecondary cellsGreen chemistryElectron

The invention relates to a graphene-coated P@SnO2 core-shell quantum dot electrode material and a preparation method and an application thereof. The method comprises the following steps: (1) preparing graphene through a Hummer method; (2) adding anhydrous stannous chloride to ethanolamine, stirring and dissolving the anhydrous stannous chloride to obtain a solution, then sequentially adding red phosphorus and graphene and carrying out ultrasonic mixing to obtain a black solution; and (3) transferring the black solution into a reaction kettle for hydrothermal reaction in an oven, cooling and washing the black solution with ethyl alcohol, and drying the black solution to obtain the electrode material finally. The graphene-coated P@SnO2 core-shell quantum dot electrode material has the beneficial effects that the ion / electron transport capacity of the material is improved; the diffusion path of the material is lowered; the cycling stability of the electrode material is effectively improved; the graphene-coated P@SnO2 core-shell quantum dot anode material is prepared through a hydrothermal method; and the graphene-coated P@SnO2 core-shell quantum dot anode material demonstrates the characteristics of high discharge capacity, high power and good cycling stability when taken as an anode active material of a lithium-ion battery, is high in feasibility and easy to amplify, and conforms to the characteristics of green chemistry.

Owner:WUHAN UNIV OF TECH

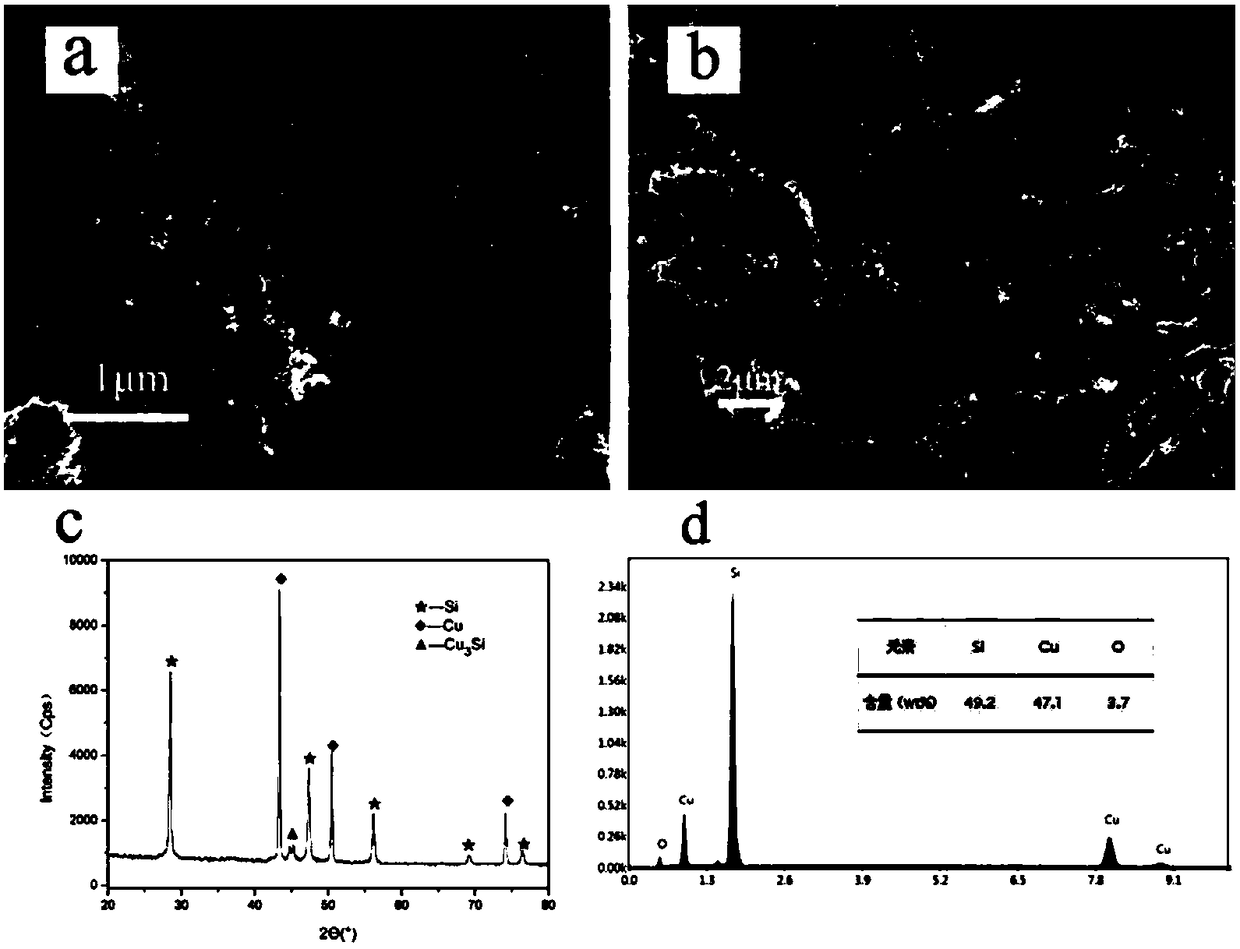

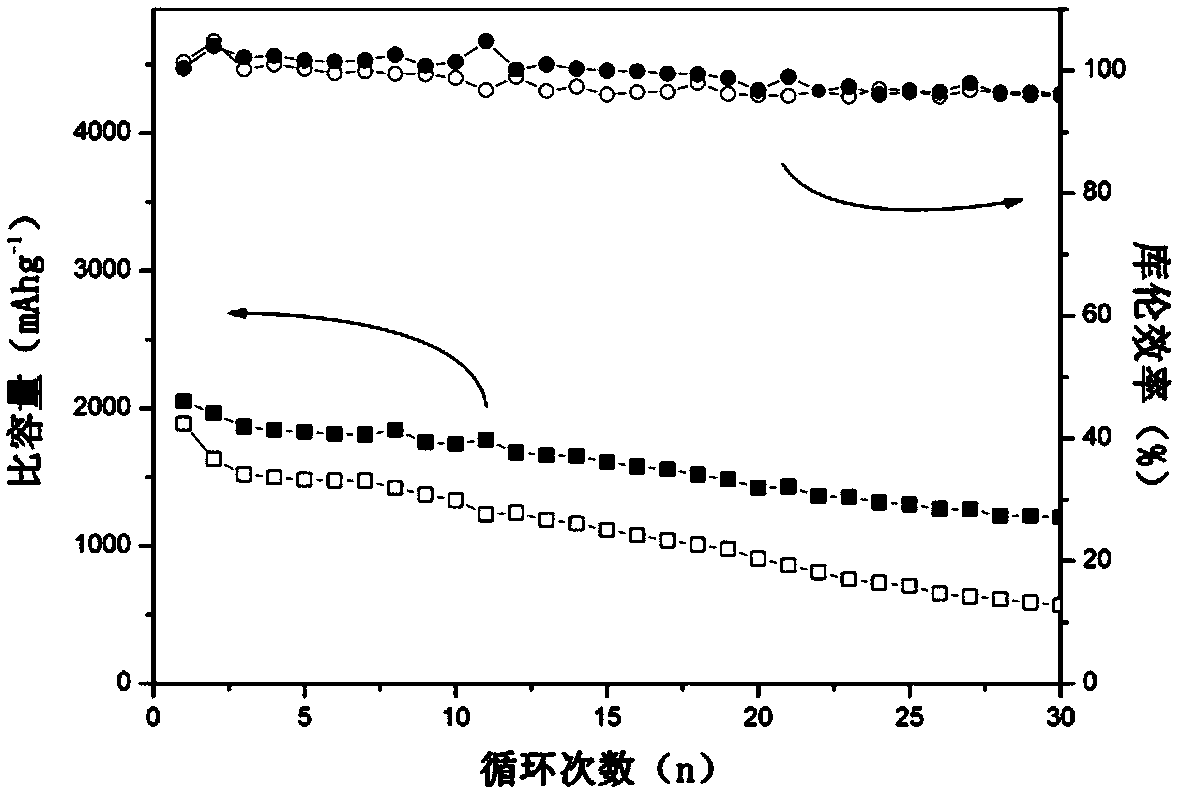

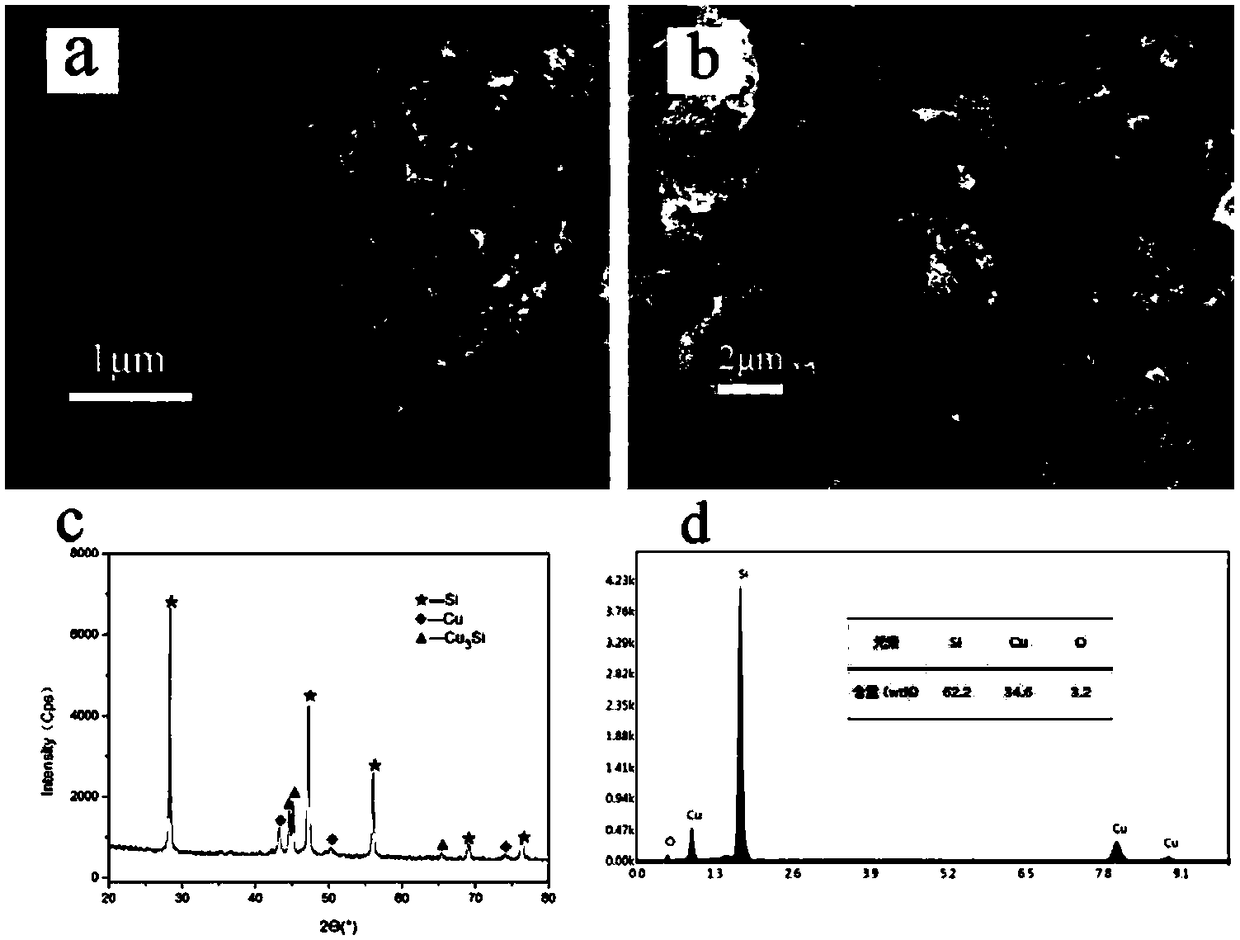

A kind of porous silicon-copper composite material and its preparation method and application

ActiveCN105826528BSolve the real problemVolume expansion limitCell electrodesSecondary cellsLithiumSize change

The invention discloses a method for preparing a porous silicon-copper composite material.The preparation method specifically comprises the steps that CuO powder and Mg2Si powder are mixed to be uniform to be subjected to heat treatment at the temperature of 600 DEG C-700 DEG C and then subjected to acid pickling and aftertreatment to obtain the porous silicon-copper composite material.According to the preparation method, the preparation technology is simple, the great operability is achieved, the adopted raw materials are rich in source and low in price, and the adopted method way is easily conducted in a factory; particularly, a replacement reaction of magnesium and copper oxide is ingeniously utilized, nano-scale copper particles are generated and uniformly dispersed on the surface of porous silicon while porous silicon is prepared, and the improvement role of copper on the conductivity of a whole material system and the buffer role of the copper particles on the size changes of silicon during extraction and insertion of lithium ions are more fully played.Through the potential method, the silicon-copper composite material with a unique structure can be massively synthesized.

Owner:ZHEJIANG UNIV

A kind of superhydrophobic powder coating and preparation method thereof

ActiveCN109651920BImprove stabilityHas surface chemical composition repair functionAnti-corrosive paintsPowdery paintsSuperhydrophobeCoated surface

The invention discloses a superhydrophobic powder coating, which includes functional fillers, and is characterized in that the functional fillers include porous particles, low surface energy substances and vulcanized silicone rubber; the preparation method is: adsorbing low surface energy substances on porous The step of obtaining modified porous particles inside the pores of the particles; and the step of wrapping the surface of the modified porous particles with the vulcanized silicone rubber to obtain the functional filler. It solves the problem that the existing superhydrophobic coating surface only enhances the superhydrophobic durability of the coating surface through a single repair chemical composition substance, and the method of the present invention repairs the microstructure and chemical composition substances of the damaged superhydrophobic coating surface at the same time, effectively Improves the hydrophobic durability of the coated surface.

Owner:NORTHEAST GASOLINEEUM UNIV

CF/PPS composite material with high impact toughness and preparation method thereof

ActiveCN111393689BGuaranteed normal windingMake up or offset the lossInterlaminar shearSaturated water vapor

The invention relates to a CF / PPS composite material with high impact toughness and a preparation method of the CF / PPS composite material. The preparation method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing the ACF into polyether sulfone / dimethylformamide, and drying to obtain sized carbon fiber MCF; (4) laminating and hot-pressing the MCF anda PPS material; (5) cooling to a certain temperature at a rate of 50-70 DEG C / min after hot pressing is finished, applying a certain pressure, maintaining the pressure for a period of time, and then relieving the pressure to obtain the CF / PPS composite material with high impact toughness. The tensile strength of the composite material is 650-820 MPa, the tensile modulus of the composite material is 50-63 GPa, the interlaminar shear strength of the composite material is 60-80 MPa, and the residual compression strength of the composite material after impact is 260-300 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared composite material can replace metal to be applied to the fields of aerospace, machinery, automobiles, rail transit, petroleum transportation and the like.

Owner:合肥东华复材科技有限公司

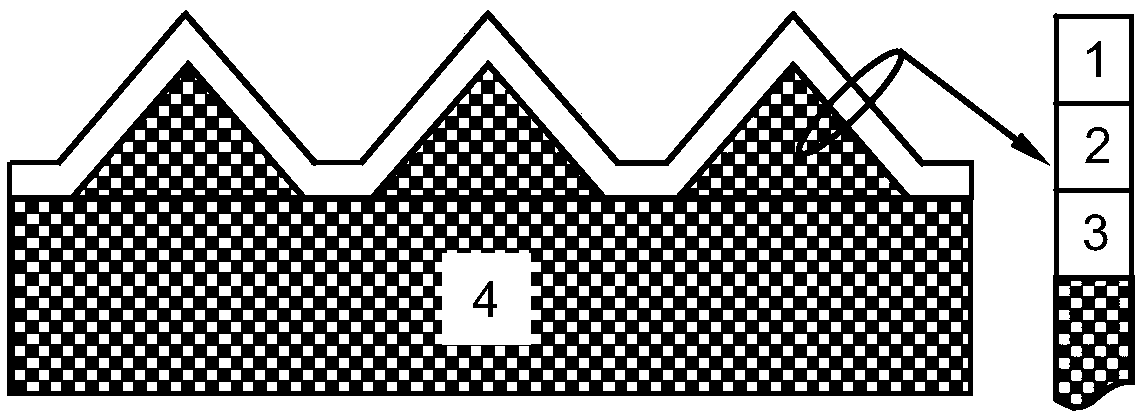

Sapphire pattern substrate structure capable of improving luminous efficiency of GaN-based LED

PendingCN108598232AQuality improvementImprove luminous efficiencySemiconductor devicesSapphireLuminous efficacy

The invention discloses a sapphire pattern substrate structure capable of improving the luminous efficiency of a GaN-based LED. The sapphire pattern substrate structure comprises: a sapphire pattern substrate and a sandwich reflection structure deposited on the sapphire pattern substrate. The sandwich reflection structure consists of a first Al2O3 multilayer structure deposited on the sapphire pattern substrate, a Bragg reflector deposited on the first Al2O3 multilayer structure, and a second Al2O3 multilayer structure deposited on the Bragg reflector. Therefore, the quality of the GaN-based LED material and the luminous efficiency of the GaN-based LED are improved. The sapphire pattern substrate structure has the great commercial value.

Owner:ZHEJIANG UNIV

Composite multilayer crucible for beryllium aluminum alloy induction melting and preparation method thereof

ActiveCN109824370BImprove structural strengthChemically stableLayered productsMaterials scienceAluminium alloy

The invention discloses a composite multilayer crucible for beryllium-aluminum alloy induction melting and a preparation method thereof, which solves the problem in the prior art that there is no crucible suitable for beryllium-aluminum alloy induction melting. The composite multi-layer crucible of the present invention comprises an inner layer crucible, a middle layer crucible and an outer layer crucible which are fixedly connected sequentially from the inside to the outside; the inner layer crucible is composed of 92.5-97.5 parts of beryllium oxide, 1.0-2.0 parts of calcium oxide, and 0.5-2.0 parts of yttrium oxide. 2.0 parts, made of 1.0-3.5 parts of silicon carbide; the middle crucible is made of graphite; the outer crucible is made of 90-95 parts of calcium oxide, 1-3 parts of magnesium oxide, 2-4 parts of yttrium oxide, and 1-1.5 parts of zirconia , made from 0.5 to 1.5 parts of clay. The composite multilayer crucible structure of the invention has high structural strength and can shield a considerable part of the induced magnetic field. The chemical properties are stable, there is no splashing of the melt during the melting process, the degree of oxygenation is low, and some single-layer structures are replaceable and reusable, with long service life.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Silver nanotube network film based on electromagnetic interference shielding and preparation method thereof

ActiveCN114161795AAvoid damageBrittleFibre typesSynthetic resin layered productsFilm baseElectromagnetic interference

The invention belongs to the technical field of electromagnetic shielding materials, and particularly relates to a silver nanotube network film based on electromagnetic interference shielding and a preparation method. Based on a uniform and large-scale nanofiber skeleton, a stable, integrated and interconnected high-performance silver nanotube network film is prepared by adopting a physical deposition technology. The simple integrated preparation process can bring high comprehensive performance to a large-scale AgNTs network. The results show that the flexible transparent EMI shielding film based on the AgNTs network has huge potential in aviation and industrial optical systems and has a good market prospect.

Owner:DALIAN UNIV OF TECH

A pressure-responsive aromatic sustained-release microcapsule, its preparation method and its application

ActiveCN108816163BAffect the sustained release effectAvoid the problem of accelerated churnEssential-oils/perfumesMicroballoon preparationPolymer scienceLatex rubber

The invention relates to a pressure-responsive fragrant sustained-release microcapsule, and a preparation method and an application thereof. The microcapsule comprises a core material and a wall material coated outside the core material. The preparation method comprises the following steps: dispersing an essence-adsorbed porous silicon dioxide powder into deionized water under stirring, adding nanometer silicon dioxide, natural latex and a cross-linking agent I for cross-linking so as to prepare the pressure-responsive fragrant sustained-release microcapsule. The pressure-responsive fragrant sustained-release microcapsule is applied through the following steps: adding the natural latex into the prepared microcapsule, then adding a cross-linking agent II and the deionized water, carrying out uniform dispersing, injecting a dispersion into a mold, carrying out drying, cross-linking and cooling so as to prepare an elastic material, and coating an EVA hot melt adhesive onto two sides of the elastic material so as to prepare an elastic carpet. According to the invention, the preparation method is simple; raw materials are easily-available; and the essence release speed of the fragrant sustained-release microcapsule has a certain relationship with the pressure that the fragrant sustained-release microcapsule bears, so the release effect of an essence in the interior of the microcapsule is effectively improved; the usage amount of perfumes is saved; the service life of the carpet is prolonged; and significant application prospects are achieved.

Owner:DONGHUA UNIV

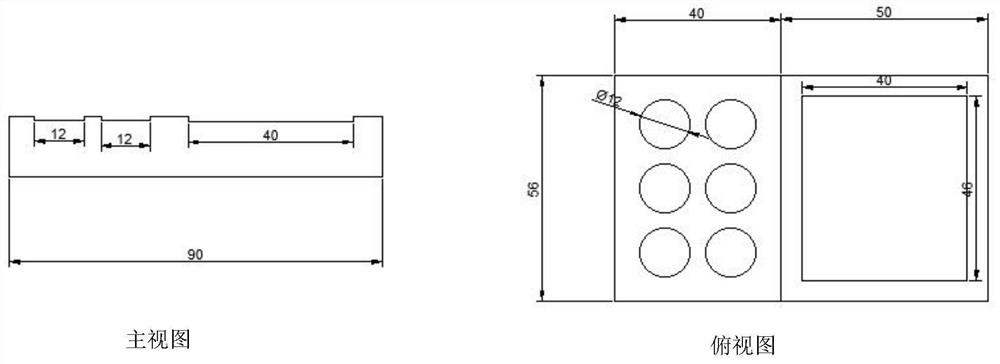

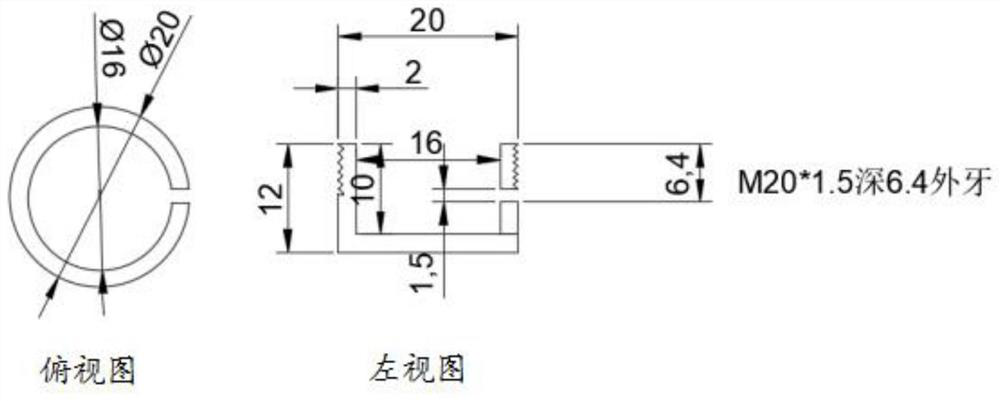

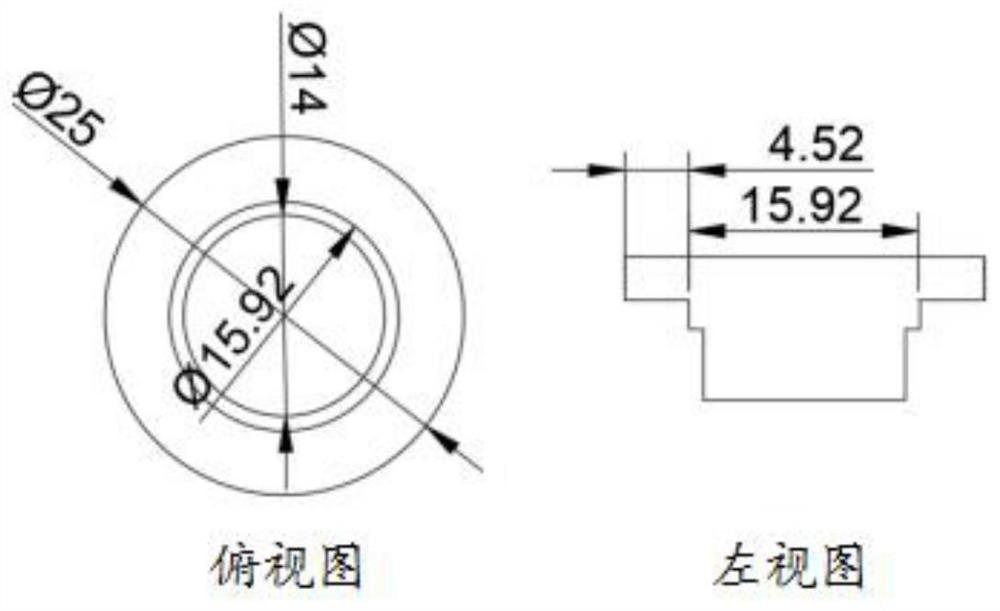

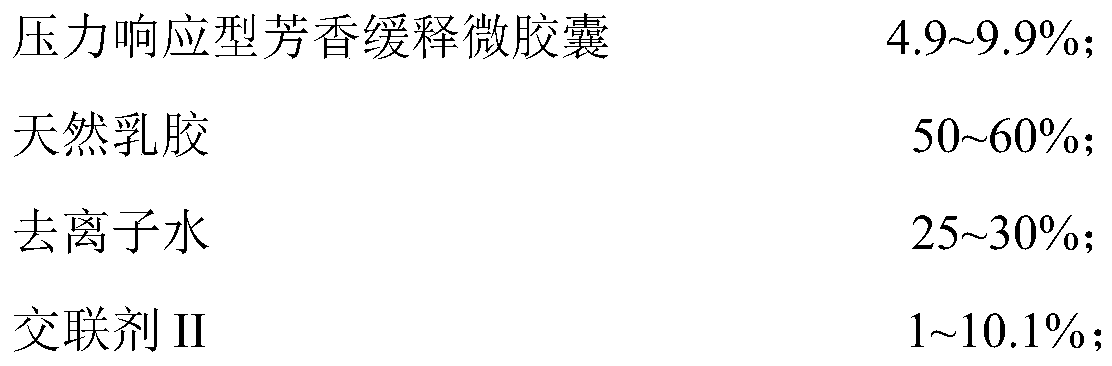

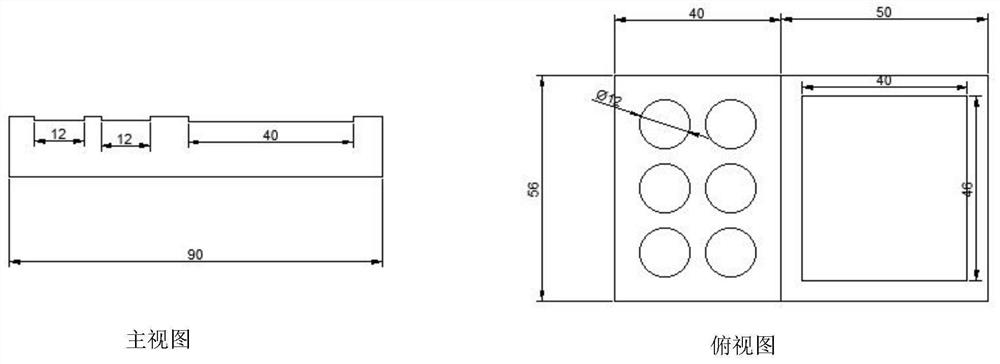

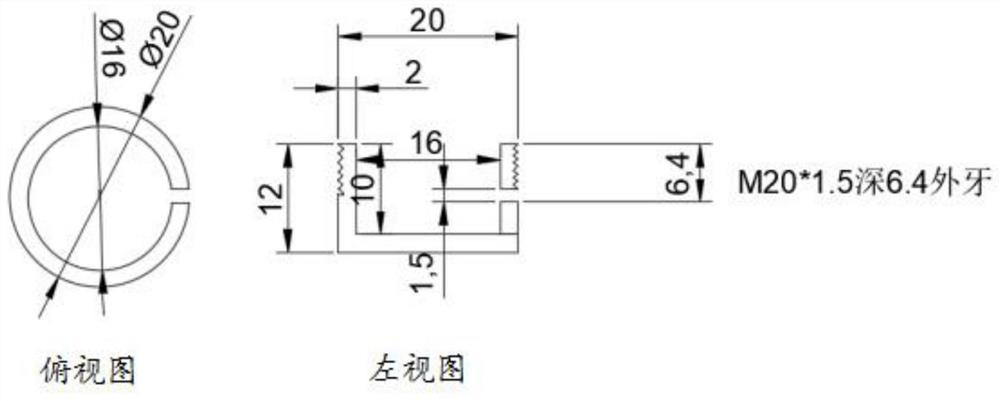

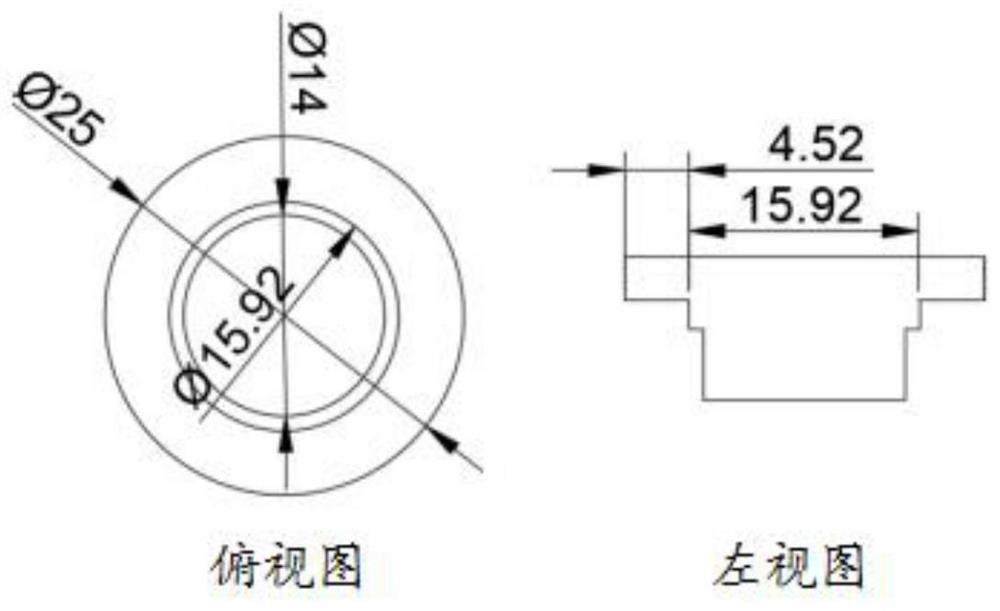

A device for quickly measuring tool wear

ActiveCN111203760BReduce labor intensityRealize one by one detectionMeasurement/indication equipmentsSortingMechanical engineeringTool wear

The invention discloses a device for rapidly measuring cutter abrasion. The device for rapidly measuring cutter abrasion comprises a first conveying belt, a plurality of clamping mechanisms are arranged on the first conveying belt, the clamping mechanisms can clamp a cutter to be detected, a cutter abrasion detector is arranged above the first conveying belt, the cutter abrasion detector is used for detecting the cutter to be detected, and a second conveying belt is arranged below the first conveying belt and is used for conveying the to-be-detected cutter separated from the clamping mechanisms. According to the device for rapidly measuring cutter abrasion, one-by-one detection of a plurality of to-be-detected cutters in the same batch can be realized, and the clamping mechanisms can be controlled to release the clamping of the to-be-detected cutters at the specified position according to the detection result, so that qualified or unqualified to-be-detected cutters are correspondinglyconveyed to different places for collection, thereby the automatic classification is realized, the overall operation efficiency of the system is effectively improved, frequent manual taking-out is notneeded, the labor intensity of workers is reduced, and the device has wide popularization value.

Owner:江苏厚道数控科技有限公司

Polymer solar cell and preparation method thereof

ActiveCN102956826BImprove collection efficiencyImprove distributionSolid-state devicesSemiconductor/solid-state device manufacturingCharge carrierSolar battery

The invention relates to a polymer solar battery and a preparation method of the polymer solar battery. The polymer solar battery comprises an anode substrate, a cavity buffer layer, an active layer and a metal cathode which are sequentially stacked, and also comprises an inorganic layer arranged between the active layer and the metallic cathode.\The polymer solar battery comprises the active layer / inorganic layer structure, the distribution of an optical field in the active layer can be improved, so that a generating region of a carrier is changed, a good place is provided for exciton dissociation, and meanwhile, the transmission efficiency of the carrier is improved; and a contacting interface of the active layer and the cathode is separated, so that metal atoms are prevented from diffusing to the active layer to further destroy the structure of the active layer, the role of a buffering layer is played, and the collection efficiency of electrons at the position of the electrode is improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

A large-scale high-toughness nano-conductive rubber sensor and its preparation and packaging method

The invention relates to the technical field of pressure measurement, and provides a large-scale high-toughness nano-conductive rubber sensor and a preparation and packaging method thereof. The invention adopts the method of high-temperature banburying to improve the dispersibility of the conductive filler, and solidifies the sandwich structure under high pressure to make the rubber structure itself more compact; the nanometer conductive rubber sensor prepared by the invention has wide measurement range, good sensitivity and stability. The invention uses a rubber matrix to encapsulate the nano-conductive rubber sensor, and uses a casing, a cover plate and a sealing cover to seal the rubber matrix encapsulated with the sensor. At the same time, the rubber matrix package makes the sensor as a whole have excellent performances such as high temperature resistance, waterproof, fire resistance, ultraviolet resistance and acid and alkali corrosion resistance, better aging resistance stability, and longer service life under high load conditions longevity and safety.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com