A device for quickly measuring tool wear

A tool wear and tool technology, used in measuring/indicating equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of low detection efficiency, error reporting and increase the workload of staff, to reduce labor intensity, improve operating efficiency, increase The effect of high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

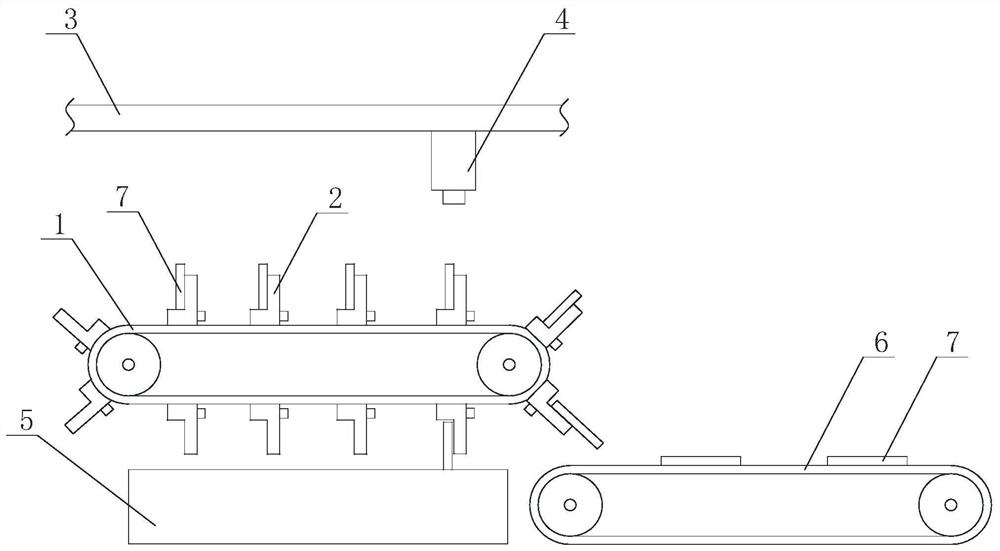

[0047] Such as figure 1 The shown device for quickly measuring tool wear includes a first conveyor belt 1, and a plurality of clamping mechanisms 2 are arranged on the first conveyor belt 1, and the clamping mechanisms 2 are capable of clamping a tool 7 to be detected. A tool wear detector 4 is arranged above the conveyor belt 1, and the tool wear detector 4 is used to detect a tool 7 to be detected, and a second conveyor belt 6 is arranged below the first conveyor belt 1, and the second conveyor belt 6 is used for transporting from The tool to be detected 7 disengaged from the clamping mechanism 2; the clamping mechanism 2 held includes a locked state and an unlocked state. In the locked state, the tool to be detected 7 is fixed relative to the clamping mechanism 2. In the unlocked state, The tool 7 to be detected can move relative to the installation groove.

[0048] In some embodiments, the tool wear detector 4 is installed on a slider, and the slider can move along the sl...

Embodiment 2

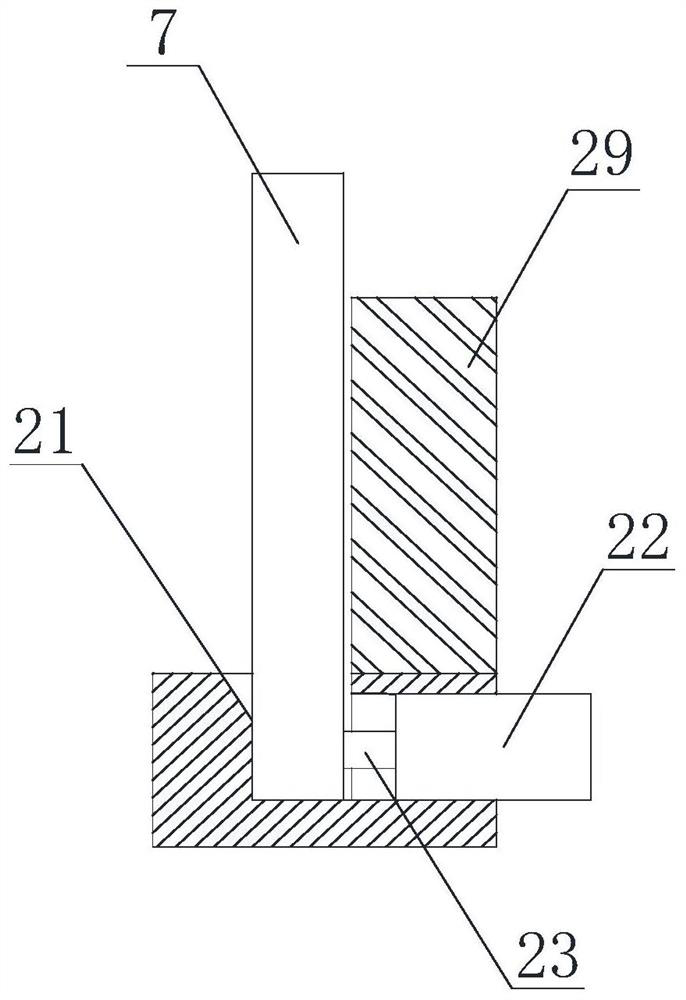

[0051] On the basis of Example 1, such as figure 2 As shown, the clamping mechanism 2 is provided with a slot 21 and an installation groove, the slot 21 is used to place the tool 7 to be detected, and a hydraulic cylinder 22 is arranged in the installation groove. In the locked state, the The piston rod 23 of the hydraulic cylinder 22 squeezes the side of the tool 7 to be detected, and the piston rod 23 and the inner wall of the slot 21 jointly form the clamping of the tool 7 to be detected; Reduced, the tool 7 to be detected can move relative to the slot 21.

[0052] In some embodiments, such as figure 2 As shown, the clamping mechanism as a whole is roughly a cylinder, and an arc-shaped baffle is arranged above the cylinder. Preferably, the center of the arc-shaped baffle is concentric with the center of the cylinder, and the position of the arc-shaped baffle is configured so that when When the clamping mechanism is located above the first conveyor belt, the arc-shaped b...

Embodiment 3

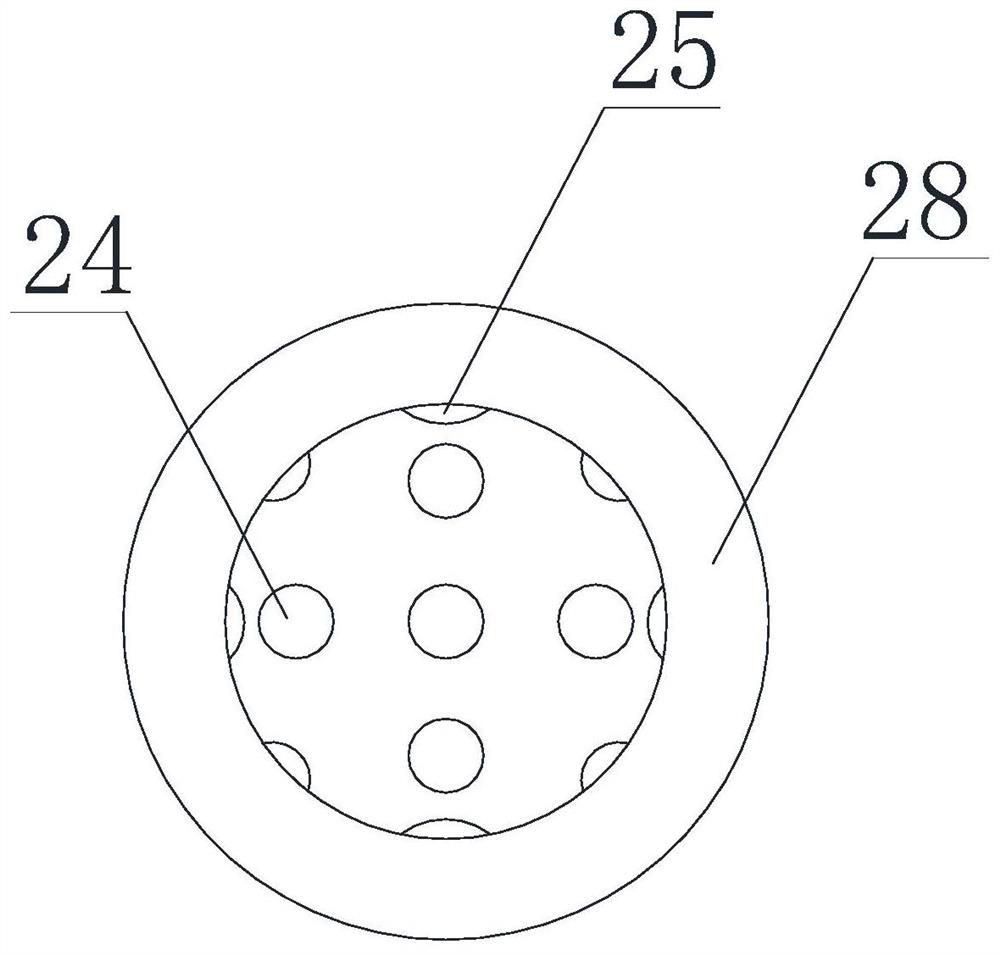

[0055] On the basis of the above examples, if image 3 and Figure 4 As shown, a protective sleeve 28 is also included, and the protective sleeve 28 can be tightly sleeved on the bottom of the tool 7 to be detected. The protective sleeve 28 is provided with a slot 26, and the size of the slot 26 is the same as that of the piston rod 23. match; the protective cover 28 is made of rubber material; the bottom of the protective cover 28 is provided with a through hole 24; the inner wall of the protective cover 28 is provided with several convex points 25; A clasp 27 is arranged inside the 26, and the clasp 27 is made of metal material.

[0056] In this embodiment, by setting the protective cover, on the one hand, it can play the role of a buffer layer, avoiding the surface of the piston rod from scratching the side of the tool to be detected, and increasing the friction between the two. On the other hand, the protective cover has a thickness and can The deformability can fill the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com